6061/6063 Aluminum Insulation for Steam Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

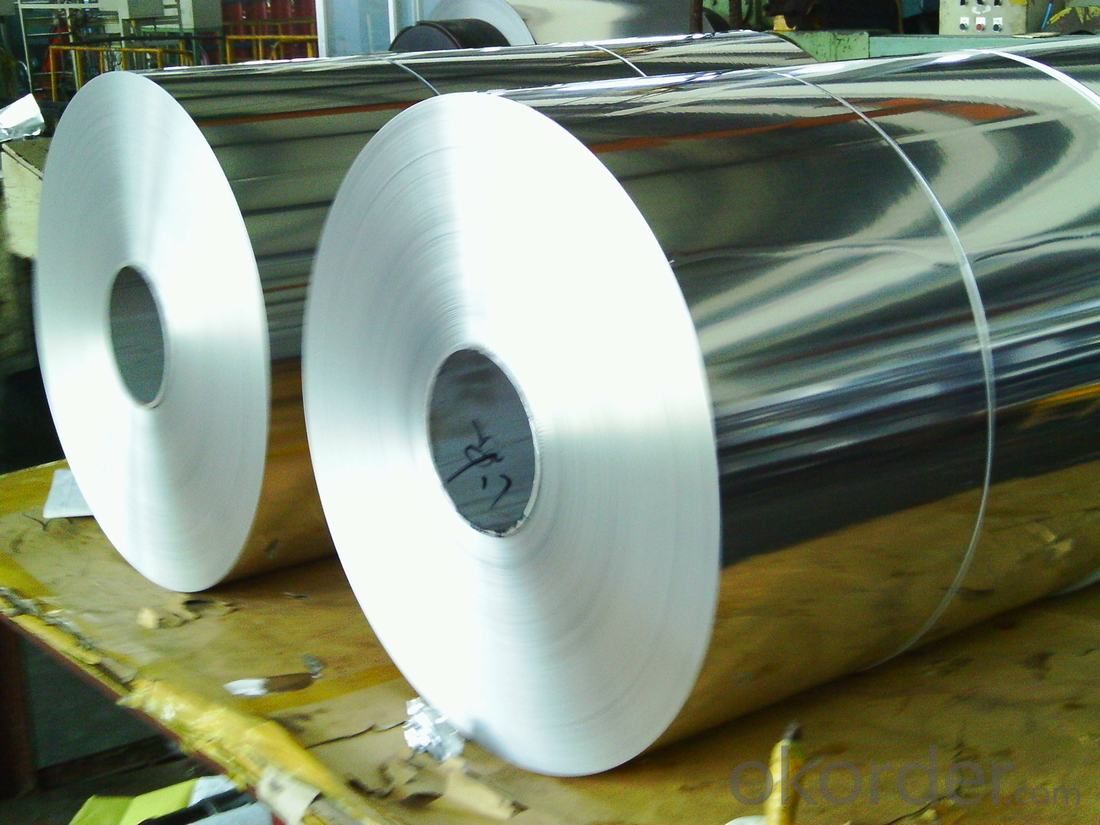

6061/6063 Aluminum Insulation for Steam Pipe

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

Place | China |

Grade | Aluminium coil & roll |

Alloy | 1100,1050,1060,3003,3105,5052,5083,8011 |

Temper | O,H12,H14,H16,H18,H19,H22,H24 |

Standard | GB/T3 190-1999 GB/T3 190-2003 YS/T 430-2000 |

Width | 15mm-2200mm |

Length | customized avaiable |

Inner Diameter | 75mm,150mm,200mm,220mm,300mm,405mm |

Application | Widely used in air-conditioning,cable,exchanger,cigarettes,food,medicine, decoration,packing,electrical and products,etc. |

Character. |

|

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight and durable material that is commonly used in the construction of bus bodies. Its high strength-to-weight ratio makes it an ideal choice for bus manufacturers, as it allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, which is beneficial for vehicles that are constantly exposed to various weather conditions. Moreover, aluminum can be easily formed and fabricated, allowing for the creation of complex shapes and designs. Overall, aluminum sheets are a popular choice for bus bodies due to their strength, lightness, corrosion resistance, and versatility.

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: Describe the process of selecting an appropriate color for an exterior wall made from aluminum sheets.

- <p>Choosing a suitable color for an exterior wall made of aluminum sheets involves considering several factors. First, think about the architectural style and the existing color scheme of the building. Neutral colors like white, gray, or beige are versatile and can complement most designs. Consider the local climate; lighter colors reflect heat and are suitable for hot climates, while darker colors can absorb heat, making them ideal for cooler regions. Factor in the environment and surroundings; colors that blend with the natural landscape can create a harmonious look. Additionally, consider the maintenance and durability of the color, as some may fade or show dirt more easily. Finally, consult with an architect or designer for professional advice tailored to your specific project.</p>

- Q: Can the aluminum sheets be used for manufacturing heat exchanger fins?

- Yes, aluminum sheets can be used for manufacturing heat exchanger fins. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity and corrosion resistance. The lightweight and malleable nature of aluminum sheets make them ideal for forming fins with high surface area to enhance heat transfer. Additionally, aluminum is readily available and cost-effective, making it a popular choice in heat exchanger manufacturing.

- Q: avaliable in the uk preferably in a high street store and preferably anti-perperant aswell

- Are you allergic to aluminum or are you refusing to use it because it is not natural? Aluminum has solid research to back its antiperspirant ability. As long as the deodorant or antiperspirant is well-formulated, it is good. There is no best. You should make a search on Amazon UK with key word like natural or organic deodorant or antiperspirant because those terms usually filter out aluminum ones. But, whether or not it will be effective is a different story.

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: Can aluminum sheets be used for modular construction?

- Yes, aluminum sheets can be used for modular construction. Aluminum is a versatile and lightweight material that offers several benefits for modular construction projects. It is durable, corrosion-resistant, and has a high strength-to-weight ratio, making it suitable for various structural applications. Aluminum sheets can be easily fabricated and formed into different shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum is recyclable, making it an environmentally friendly choice for sustainable construction practices. Overall, aluminum sheets are a viable option for modular construction due to their strength, durability, and versatility.

- Q: What is the cost of an aluminum sheet?

- The cost of an aluminum sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or conduct market research to get accurate and up-to-date pricing information.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Can aluminum sheets be used for lithographic printing plates?

- Yes, aluminum sheets can be used for lithographic printing plates. Aluminum is commonly used in lithography due to its excellent characteristics such as light weight, corrosion resistance, and durability, which make it suitable for the printing process.

Send your message to us

6061/6063 Aluminum Insulation for Steam Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords