5xxx Series Color Coated Aluminum Coil for Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil for Curtain Wall System

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coated Aluminum Coil for Curtain Wall System

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil for Curtain Wall System

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

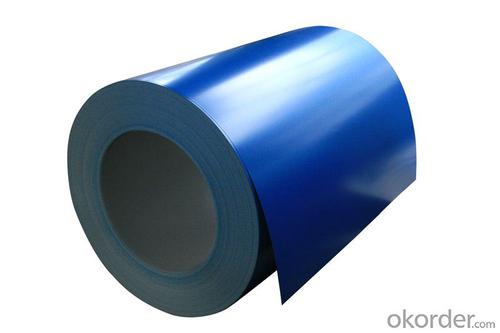

5. Image of Color Coated Aluminum Coil for Curtain Wall System

6. Package and shipping of Color Coated Aluminum Coil for Curtain Wall System

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for manufacturing cookware?

- Yes, aluminum coils are suitable for manufacturing cookware. Aluminum is a popular choice for cookware due to its excellent heat conductivity, which allows for even heating and efficient cooking. It also has a lightweight and durable nature, making it easy to handle and long-lasting. Additionally, aluminum is resistant to rust and corrosion, making it an ideal material for cookware that is frequently exposed to water and heat. However, it is important to note that uncoated aluminum cookware may react with certain acidic or alkaline foods, leading to a metallic taste. To overcome this, many aluminum cookware manufacturers use non-stick coatings or anodized finishes to prevent food reactions and improve the durability of the cookware. Overall, aluminum coils are a suitable material for manufacturing cookware, but it is essential to consider the specific requirements and coatings needed for different types of cookware to ensure safety and optimal performance.

- Q: How are aluminum coils protected against UV exposure during storage?

- Aluminum coils are typically protected against UV exposure during storage through the application of a protective coating or the use of UV-resistant packaging materials. Aluminum coils are highly susceptible to UV degradation, which can result in discoloration, surface damage, and reduced performance. Therefore, manufacturers and distributors take special precautions to ensure that the coils are shielded from harmful UV rays. One common method is the application of a protective coating on the surface of the coils. This coating acts as a barrier between the aluminum material and UV radiation, preventing direct exposure. The coating is typically a specialized paint or lacquer that contains UV inhibitors, which absorb or reflect UV rays, thereby minimizing damage to the coils. This protective layer also helps to preserve the aesthetic appearance of the coils and extend their lifespan. In addition to coatings, aluminum coils can also be stored in UV-resistant packaging materials. These materials are designed to block or absorb UV radiation, effectively creating a shield around the coils. Common UV-resistant packaging materials include polyethylene films, which are specifically formulated to provide excellent UV protection. By storing the coils in such packaging, they are safeguarded against direct sunlight and other sources of UV radiation. It is worth noting that UV protection measures are particularly crucial during long-term storage or transportation, as the coils may be exposed to UV rays for extended periods. By implementing these protective measures, manufacturers and distributors ensure that the aluminum coils maintain their quality and performance, even when stored in environments with high UV exposure.

- Q: How are aluminum coils used in the production of consumer electronics?

- Consumer electronics rely heavily on the utilization of aluminum coils for a multitude of purposes. A prevalent example is their application in the creation of heat sinks. These heat sinks are instrumental in dissipating the heat produced by electronic components like microprocessors, thus averting overheating and ensuring optimal performance. To achieve this, aluminum coils are often molded into fins or plates and subsequently affixed to these components, exploiting the exceptional thermal conductivity of aluminum. Another way aluminum coils find use in the realm of consumer electronics is through their incorporation into electromagnetic shields. The primary objective of these shields is to obstruct or redirect electromagnetic interference (EMI) generated by electronic devices. Given aluminum's exceptional electrical conductivity, it is an ideal material for the construction of these shields. Manufacturers shape the coils into diverse forms and sizes in accordance with the specific requirements of the electronic device, seamlessly integrating them into the overall design to minimize EMI. In addition, aluminum coils serve a vital purpose in the production of electrical connectors and wiring within consumer electronics. Aluminum's lightweight nature, durability, and commendable electrical conductivity make it an excellent choice for these applications. Manufacturers frequently process and shape the coils into thin, flexible strips or wires that can be effortlessly integrated into the electronic circuitry. To summarize, the indispensability of aluminum coils in the manufacturing process of consumer electronics is undeniable. Their ability to function as heat sinks for thermal management, electromagnetic shields for EMI protection, and electrical connectors and wiring for efficient electrical conductivity underscores their versatility. Coupled with their outstanding thermal and electrical properties, aluminum coils are an integral component in the production of a diverse range of consumer electronic devices.

- Q: Are aluminum coils resistant to mold and mildew?

- Generally, aluminum coils have resistance to mold and mildew. Unlike materials like wood or fabric, aluminum is non-porous and does not absorb moisture. This characteristic reduces its susceptibility to mold and mildew growth. Moreover, protective finishes are often applied to aluminum coils, enhancing their resistance to mold and mildew. Nevertheless, it is important to remember that although aluminum coils are less prone to mold and mildew, they are not entirely immune. If exposed to excessive moisture or humidity, mold and mildew can still develop. Thus, regular cleaning and maintenance are essential to prevent potential mold or mildew growth.

- Q: Can aluminum coils be used in automotive body panels?

- Automotive body panels can indeed utilize aluminum coils. Being both lightweight and corrosion-resistant, aluminum proves to be a suitable material for automotive purposes. The employment of aluminum coils in body panels yields numerous benefits, such as enhanced fuel efficiency owing to the reduced vehicle weight, improved handling and maneuverability, and increased durability. Moreover, aluminum boasts high recyclability, rendering it an environmentally conscious alternative for automotive production. Numerous automakers have already begun integrating aluminum coils into their vehicles, and this trend is anticipated to persist as the industry aims for lighter and more environmentally sustainable automobiles.

- Q: Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

- Q: How are aluminum coils protected against moisture during storage?

- Various methods and materials are typically employed to safeguard aluminum coils against moisture during storage. One commonly utilized technique involves the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which establishes a barrier between the coil and any moisture present in the surroundings. This coating effectively prevents direct contact between the aluminum surface and water, thereby minimizing the likelihood of corrosion or other forms of moisture-induced harm. In addition to protective coatings, it is possible to store aluminum coils in a controlled environment with low humidity levels. This can be accomplished by placing the coils in a dry warehouse or utilizing dehumidifiers to eliminate excess moisture from the storage area. By regulating the humidity, the probability of moisture condensation on the coils is diminished, affording them further protection against potential damage. Moreover, appropriate packaging plays a vital role in shielding aluminum coils from moisture during storage. Frequently, the coils are enveloped in moisture-resistant materials, such as plastic or moisture-proof paper, which create a barrier to prevent moisture from reaching the coils. Additionally, the packaging is often sealed to establish an airtight environment, thereby minimizing the chances of moisture infiltration. Regular inspection and maintenance are also crucial to ensure the ongoing protection of aluminum coils during storage. This entails examining the integrity of the protective coatings, monitoring the storage environment for any fluctuations in humidity levels, and promptly addressing any indications of moisture damage. On the whole, the utilization of protective coatings, controlled storage environments, appropriate packaging, and regular maintenance are key elements in safeguarding aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the coils' quality and integrity until they are ready for utilization.

- Q: Can aluminum coils be used for food storage containers?

- Indeed, food storage containers can be made from aluminum coils. Aluminum is widely chosen as a material for such containers because of its numerous advantageous qualities. Notably, it is lightweight, sturdy, and possesses exceptional thermal conductivity, enabling it to distribute heat evenly for effective cooking or cooling purposes. Moreover, aluminum is non-toxic, devoid of odor, and resistant to corrosion, rendering it a secure option for food storage. Additionally, it acts as a proficient shield against light, moisture, and oxygen, thereby assisting in maintaining the freshness and quality of the stored food. All in all, opting for aluminum coils for food storage containers can be a dependable and practical decision.

- Q: Can aluminum coils be recycled multiple times?

- Aluminum coils possess the remarkable ability to be recycled numerous times. This is due to the fact that aluminum is an exceptionally recyclable substance, and its quality remains unaltered throughout the recycling process. As a result, aluminum coils can be melted and reshaped into fresh coils on multiple occasions, without experiencing any deterioration in their performance or characteristics. The act of recycling aluminum not only aids in the preservation of natural resources, but it also conserves a significant amount of energy compared to the production of new aluminum using raw materials. Consequently, opting for aluminum coils is a sustainable and eco-friendly decision, as they can be recycled multiple times.

- Q: What are the typical dimensions for aluminum coils?

- <p>The standard size of aluminum coils can vary depending on the specific application and industry requirements. Commonly, aluminum coils are available in widths ranging from 600mm to 2000mm and thicknesses from 0.2mm to 6.0mm. The length of the coils can be from 500 meters to over 3000 meters, depending on the weight and the manufacturing process. It's important to note that these dimensions are not fixed and can be customized to meet specific project needs.</p>

Send your message to us

5xxx Series Color Coated Aluminum Coil for Curtain Wall System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords