5083 Aluminum Sheets Canada for Marine Use Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

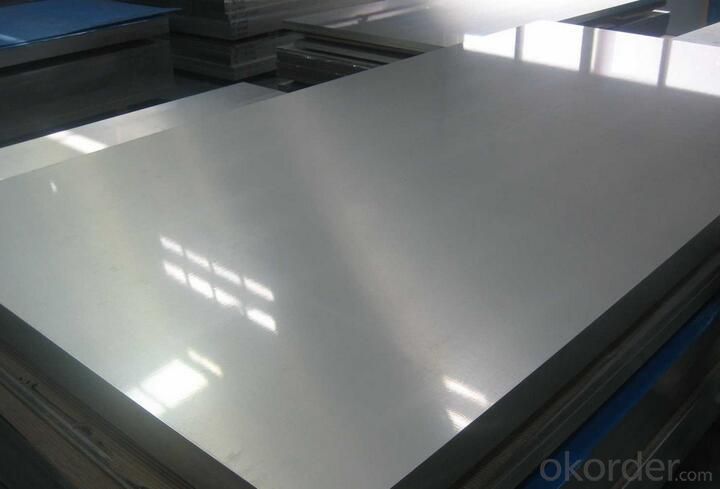

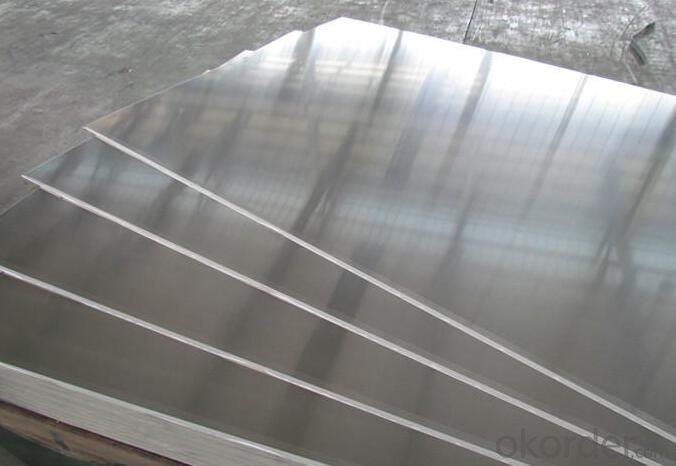

5083 Aluminium Sheet for Marine Use Material

1. Commodity: 5083 Aluminium Plain Sheet for Marine Use

2. Alloy No.: 050 1060 1100 3003 3004 3104 3005 3105 5005 5052 8011

3. Size: Thickness: 0.15-5.00mm(Tolorance±0.02mm) Width:200-1600mm(Tolorance±1mm) Length:500-1500mm(Tolorance±1mm)

4.Application:

1) air plane, refrigerators ,audio equipment

2)building materials: ceilings, walls

3)telephones, digital cameras

4) plastic composite board, aluminum and plastic pipe

5.Month Capacity: 5000MT/Month

6.Pattern: 2 bars, 3 bars, 5 bars, diamond bar

1. | Item | Aluminum plate/ Aluminum sheet,aluminium plate price, aluminium chequer plate,aluminium sheet,aluminium sheet price | |

2. | Standard | ATSTM,AISI,JIS,EN,GB | |

3. | Material | 1060,1200,1100,a1100P,3003,3004,5052,5652,5154,5254,5454,5083, 5086,5056,5456,2A21,2024,2014,6061,6063,7072,7075,etc. | |

4. | Specifications | Thickness | 0.5mm~200mm |

Width | 100mm~3000mm | ||

Length | 2m,3m,5.8m,6m,or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

7. | Price Term | Ex-work, FOB, CIF , CFR, etc. | |

8. | Payment Term | T/T, L/C, Western Union, etc. | |

9. | Delivery Time | According to order’s quantity. | |

10. | Package | Export standard package: bundled wooden box, suit for all kinds of transport, or be required. | |

11. | MOQ | 500kg | |

12. | Export to | Singapore,Indonesia,Ukraine,Korea,Thailand, Viet Nam, Saudi Arabia, Brazil, Spain, Canada, USA, Egypt, Iran, India, Kuwait, Dubai, Oman, Kuwait, Peru, Mexico, Iraq,Russia,Malaysia, etc. | |

13. | Application | 1) Kitchenware, food and chemical products processing and storage devices; 2) Aircraft fuel tanks, oil pipe, rivets, wire; 3) Cans cover, car body panels, steering plates, stiffeners, brackets and other components; 4) Manufacturing trucks, tower building, ship, train, furniture, machinery parts, precision machining with the tubes, rods, shaped, sheet metal. | |

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: What are the maximum dimensions available for aluminum sheets?

- The maximum dimensions available for aluminum sheets vary depending on the manufacturer and specific requirements. However, commonly available sizes range from 48 inches by 96 inches (4 feet by 8 feet) to 60 inches by 120 inches (5 feet by 10 feet).

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- The mechanical properties and performance characteristics of 101 aluminum sheets are used to evaluate their strength and durability. In terms of strength, these sheets possess moderate strength that is appropriate for various applications. They have a tensile strength of approximately 27,000 psi and a yield strength of around 21,000 psi. This means that they can withstand moderate levels of stress and load without deforming or breaking. Regarding durability, 101 aluminum sheets exhibit good resistance to corrosion, making them suitable for outdoor and marine applications. They also have high resistance to different forms of weathering, including UV radiation and extreme temperatures. Their corrosion resistance is primarily due to the presence of a thin, protective oxide layer on the surface, which prevents further oxidation and ensures long-lasting durability. However, it is important to note that 101 aluminum sheets are not the most durable option available. They are not as strong or durable as certain other aluminum alloys, such as 6061 or 7075, which have higher tensile and yield strengths. Therefore, if a project requires exceptional strength or durability, it may be advantageous to consider using a different aluminum alloy. In conclusion, 101 aluminum sheets offer moderate strength and good durability, making them suitable for a wide range of applications. Nevertheless, if the project necessitates higher strength or exceptional durability, it may be necessary to explore alternative aluminum alloys with superior mechanical properties.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are highly suitable for marine vessel construction. Aluminum possesses excellent corrosion resistance properties, making it ideal for use in saltwater environments. It is lightweight yet strong, providing a great balance between durability and weight savings. This allows for increased fuel efficiency and higher payload capacity. Additionally, aluminum is easy to fabricate, weld, and repair, making it a preferred choice for shipbuilders. Its high strength-to-weight ratio, along with its ability to withstand extreme temperatures, also makes it suitable for various marine applications, including hulls, decks, superstructures, and other structural components. Overall, the use of aluminum sheets in marine vessel construction offers numerous advantages, making it a popular choice in the maritime industry.

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- AlSO4 CaCl

- Q: How could two pieces of aluminium flakes be welded together?

- its welding strength is very high. you can use the following methods to weld two pieces of aluminum sheets together: 1, strict deformation control requirement. 3, it can prevent some flux remnant during welding. 3,the welding wire welding of low temperature M51 and M51-F is operated under 179?C.or they are welded in the situation of being especially thin.4, it can solve the welding of 3 series aluminium alloys and casting, and its welding temperature is 380-400?C.its advantage is that you don't need any flux during welding. WE53 low temperature aluminium welding wire has a high affinity in welding 7 series aluminium alloys. and Q303 low temperature aluminum welding wire has a high affinity for the welding of 1 series aluminium alloys, die casting or 6 series welding materials.

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Campfires would not get that hot. However, even if they were hot enought, the aluminum in the can would not melt. It would oxidize before it had a chance to and turn into a white powder that migles among the ashes.

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Model is not important, can meet the standard requirements on the line!

- Q: What is the typical electrical conductivity of aluminum sheets?

- The typical electrical conductivity of aluminum sheets is around 35-45 million Siemens per meter (MS/m).

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is around 23.1 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, the length of an aluminum sheet will increase by approximately 23.1 millionths of its original length. It is important to note that this value can vary slightly depending on the specific alloy and processing conditions of the aluminum sheet.

Send your message to us

5083 Aluminum Sheets Canada for Marine Use Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords