5083 Aluminum Coils for Sale - High Quality AA1100/AA1070 Aluminum Coils

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Thickness | 0.1mm-8mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm |

Width | 20mm-2500mm |

inner diameter | 76mm / 152mm |

Material | AA1050, AA1060, AA1070, AA1100, AA1235, AA3003, AA3004, AA3005, AA5052, AA5005, AA5754, AA5083, AA8011, AA8079, etc |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38, |

Surface | Mill finish / Coated |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 30-35 days after the receiving L/C or deposit |

2. Application of

(1) Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors, windows,

(2) Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations.

(3).Advertisement: display platforms, signboards, fascia, shop fronts.

3. Feature of

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS (if clients request, paid by client), MTC (plant provided), Certificate of Origin (FORM A, FORM E, CO), Bureau Veritas (if client request, paid by client), CIQS certificate and so on.

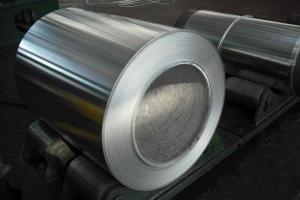

5. Image of

6. Package and shipping of

Eye to wall

Eye to the wall

With wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Depends on actual order, around 30 to 35 days

2) What is the QC system?

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used in roofing applications?

- Yes, aluminum coils can be used in roofing applications. Aluminum is a popular choice for roofing due to its lightweight nature, corrosion resistance, and durability. It is commonly used for residential and commercial roofing projects.

- Q: What are the necessary safety measures one should take while using aluminum coils in a kitchen setting?

- <p>When using aluminum coil in a kitchen, safety precautions include: 1) Ensuring proper ventilation to avoid inhaling fumes, as aluminum dust can be harmful. 2) Wearing protective gear such as gloves and goggles to protect your skin and eyes from potential contact with aluminum or sharp edges. 3) Handling the aluminum coil carefully to prevent cuts or injuries. 4) Avoiding contact with acidic or alkaline substances, as aluminum can react with them. 5) Not using aluminum coil near open flames or high heat sources, as it can melt or cause fires. 6) Cleaning up any aluminum dust or debris promptly to prevent slipping hazards. 7) Storing aluminum coils in a dry, cool place away from chemicals and heat sources.</p>

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum is a lightweight and corrosion-resistant material that has excellent thermal conductivity. These properties make it suitable for various applications where low-friction is desired. In industries such as automotive, aerospace, and HVAC systems, aluminum coils are often used in heat exchangers, evaporators, condensers, and cooling coils. These coils are designed to efficiently transfer heat, while minimizing friction and energy loss. Additionally, aluminum coils can be used in electrical motors, generators, and transformers, where low friction is essential for smooth operation and reduced energy consumption. The lightweight nature of aluminum also helps to reduce the overall weight of the system, leading to improved efficiency. Furthermore, aluminum coils can be utilized in various types of machinery and equipment that require low friction, such as conveyor systems, sliding mechanisms, and bearings. Aluminum's low coefficient of friction allows for smooth and efficient movement, minimizing wear and tear on the components. Overall, aluminum coils are a versatile solution for low-friction applications due to their lightweight, corrosion-resistant, and thermally conductive properties. Their use can lead to improved energy efficiency, reduced maintenance costs, and enhanced performance in a wide range of industries.

- Q: Are aluminum coils suitable for high-reflective applications?

- Yes, aluminum coils are highly suitable for high-reflective applications. Aluminum has excellent reflective properties, making it ideal for a wide range of applications requiring high reflectivity, such as solar panels, LED lighting, and reflective coatings. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it a preferred choice for various industries.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils in heat exchanger fins allows for efficient transfer of heat between two fluids, making it an ideal material for this application. Additionally, aluminum coils can be easily formed into various fin shapes, providing flexibility in design and maximizing the surface area for heat transfer. Overall, aluminum coils are commonly used in heat exchanger fins to enhance heat transfer efficiency and improve the overall performance of the heat exchanger system.

- Q: How do aluminum coils contribute to sustainable transportation systems?

- Aluminum coils play a significant role in promoting sustainable transportation systems in several ways. Firstly, aluminum is a lightweight material that helps reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced carbon emissions. The use of aluminum coils in vehicle manufacturing can contribute to enhancing the fuel economy of automobiles, which is crucial for sustainable transportation. Moreover, aluminum is a highly recyclable material, with nearly 75% of all aluminum ever produced still in use today. This recyclability factor makes aluminum coils a sustainable choice as they can be easily recycled and reused without compromising their quality. By incorporating recycled aluminum coils into vehicle production, manufacturers can reduce energy consumption and greenhouse gas emissions associated with primary aluminum production. Additionally, aluminum is highly resistant to corrosion, making it a durable material for various automotive applications. The longevity of aluminum coils ensures that vehicles require less maintenance and replacement parts, reducing waste and contributing to sustainable transportation systems. Furthermore, the use of aluminum coils in electric vehicles (EVs) is particularly advantageous. EVs require lightweight components to maximize battery efficiency and increase the driving range. Aluminum coils fulfill this requirement by providing the necessary lightweight construction without compromising safety or performance. By enabling the production of lightweight EVs, aluminum coils contribute to the wider adoption of electric vehicles, which have a significantly lower carbon footprint compared to traditional internal combustion engine vehicles. In summary, aluminum coils contribute to sustainable transportation systems by reducing vehicle weight, improving fuel efficiency, and reducing carbon emissions. Their recyclability, durability, and compatibility with electric vehicles further enhance their sustainability credentials. Incorporating aluminum coils in vehicle manufacturing is a step towards achieving a greener and more sustainable transportation future.

- Q: Are aluminum coils suitable for marine applications?

- Yes, aluminum coils are suitable for marine applications due to their excellent corrosion resistance properties in saltwater environments.

- Q: This question asks about the current market demand for aluminum coil, which is a versatile material used in various industries.

- <p>The market demand for aluminum coil is significant and growing due to its wide range of applications across industries such as construction, automotive, aerospace, packaging, and electronics. Its lightweight, corrosion resistance, and recyclability make it a preferred material for many applications. The demand is influenced by economic growth, technological advancements, and sustainability initiatives. As countries focus on greener construction and manufacturing processes, the demand for aluminum coil is expected to increase further.</p>

- Q: Can aluminum coils be anodized for enhanced durability?

- Indeed, it is possible to anodize aluminum coils in order to enhance their durability. Anodization involves the creation of a layer of aluminum oxide on the surface of the aluminum, resulting in increased resistance to corrosion, wear, and scratches. This layer also offers added protection against UV rays and harsh environmental conditions. By subjecting aluminum coils to anodization, they become more resilient and capable of enduring extended use in a variety of industries, including construction, automotive, and electronics. Moreover, anodized aluminum coils can be further enhanced with additional coatings or finishes to improve their appearance and provide additional protection. Overall, anodizing aluminum coils is a widely employed and efficacious technique for boosting their durability and extending their lifespan.

- Q: How are aluminum coils used in packaging?

- Aluminum coils are commonly used in packaging as they can be easily molded into different shapes and sizes. They are used to create various packaging products such as cans, containers, and foils. The coils are converted into sheets or strips, which are then formed into the desired packaging structures through processes like rolling, cutting, and shaping. The lightweight and corrosion-resistant nature of aluminum make it an ideal choice for packaging applications, ensuring the protection and preservation of various products.

Send your message to us

5083 Aluminum Coils for Sale - High Quality AA1100/AA1070 Aluminum Coils

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords