4x4 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheets for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Embossed Aluminum Sheets for Different Usages

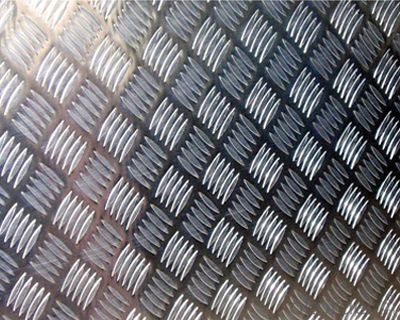

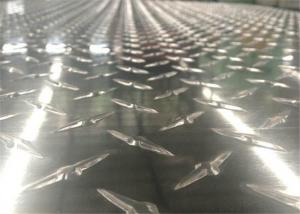

Our Embossed Aluminum Sheets for Different Usages have different patterns including diamond, stucco, big five bars, small five bars, etc.

Embossed Aluminum Sheets for Different Usages are widely used in decorative purchase in construction, packing and appliance. They are also very popularly used in anti-slippery purchase in vehicles and public places.

2.Main Features of Embossed Aluminum Sheets for Different Usages

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Embossed Aluminum Sheets for Different Usages Images

4.Specification of Embossed Aluminum Sheets for Different Usages

Alloy: AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5052

Temper: H14, H18, H24, H26, H32

Thickness: 0.2-20mm

Width:10mm- 1500mm

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5. FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: An aluminum engine block has a volume of 4.77 and a mass of 12.88 .

- For the best answers, search on this site okorder (2.7 g / cm?) x (1 kg / 1000 g) x (100 cm / 1 m)? = 2700 kg / m?

- Q: Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. The surface of the aluminum sheet can be prepared by cleaning and etching to ensure proper adhesion of the paint or coating.

- Q: Are the aluminum sheets suitable for manufacturing lightweight structures?

- Indeed, aluminum sheets are exceptionally well-suited for the production of lightweight structures. Renowned for its low density, aluminum stands as one of the most lightweight metals on the market. This attribute renders aluminum sheets an exceptional option for a multitude of sectors that prioritize weight reduction, such as aerospace, automotive, and construction industries. Furthermore, aluminum boasts an impressive strength-to-weight ratio, enabling it to withstand substantial loads while remaining lightweight. Moreover, aluminum sheets exhibit exceptional corrosion resistance, rendering them suitable for both outdoor and marine applications. All in all, the combination of its lightness, strength, and durability positions aluminum sheets as the preferred choice for the production of lightweight structures.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a material for exterior walls in construction.

- <p>Aluminum sheets for exterior walls offer several advantages, including durability, low maintenance, and resistance to corrosion and weathering. They are lightweight, which can reduce the load on structures, and are recyclable, contributing to sustainability. Additionally, aluminum sheets can be easily shaped and painted, offering design flexibility. However, they have some disadvantages, such as being a poor insulator, which may require additional insulation for energy efficiency. They can also dent or scratch easily and may require more frequent replacement due to their lower resistance to impacts compared to materials like stone or brick. Furthermore, while they reflect heat well, they can also conduct cold, potentially leading to issues in extreme temperature conditions.</p>

- Q: How to polish aluminum sheet to be bright?

- as for polishing, fine grit sandpaper can't polish it into a mirror,but laser cutting can do it.

- Q: Can aluminum sheets be used together with other materials, specifically insulation materials?

- <p>Yes, aluminum sheets can be used in combination with other materials, including insulation materials. Aluminum is often used as a cladding material due to its durability and resistance to corrosion. When combined with insulation materials, it can enhance the thermal performance of a structure by reducing heat transfer. This combination is common in construction and roofing applications, where aluminum sheets can provide a protective outer layer while the insulation material manages thermal control. The use of aluminum with insulation materials can lead to energy-efficient buildings and improved indoor comfort.</p>

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- I'm going to show my calculations anyways Fe2O3(s) + 2 Al(s) -- 2 Fe (l) + Al2O3 (s) From the equation : 1 mole of iron (III) oxide 2 moles of aluminium -- 2 moles of iron 1 mole of aluminium oxide Given that iron = 10.0 g = 10.0 g / 55.8 g per mole = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to iron (III) oxide is 2 : 1 Therefore moles of iron (III) oxide produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (55.8 x 2 + 16.0 x 3) = 14.3 grams (corr to 3 sig fig)' a) 14.3 grams of iron (III) oxide must be used ----- Given that iron = ...... (previously calculated) ...... = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to aluminium is 1 : 1 Therefore moles of aluminium produced = 0.179 mol Convert it back to grams 0.179 x 27.0 = 4.83 grams (corr to 3 sig fig) b) 4.83 grams of aluminium must be used ----- Given that iron = 0.179 mol Because the mole ratio of iron to aluminium oxide is 2 : 1 Therefore moles of Al2O3 produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (27.0 x 2 + 16.0 x 3) = 9.13 grams (corr to 3 sig fig) c) 9.13 grams of aluminium oxide is the maximum mass that could be produced P.S. The relative molecular masses used are from my textbook

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is approximately 22.2 x 10^-6 per degree Celsius.

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

Send your message to us

4x4 Aluminum Diamond Plate Sheets - Embossed Aluminum Sheets for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords