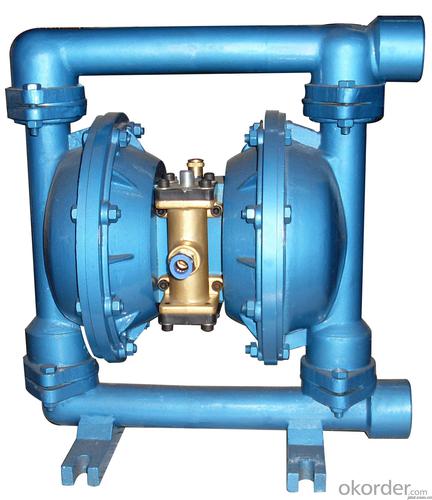

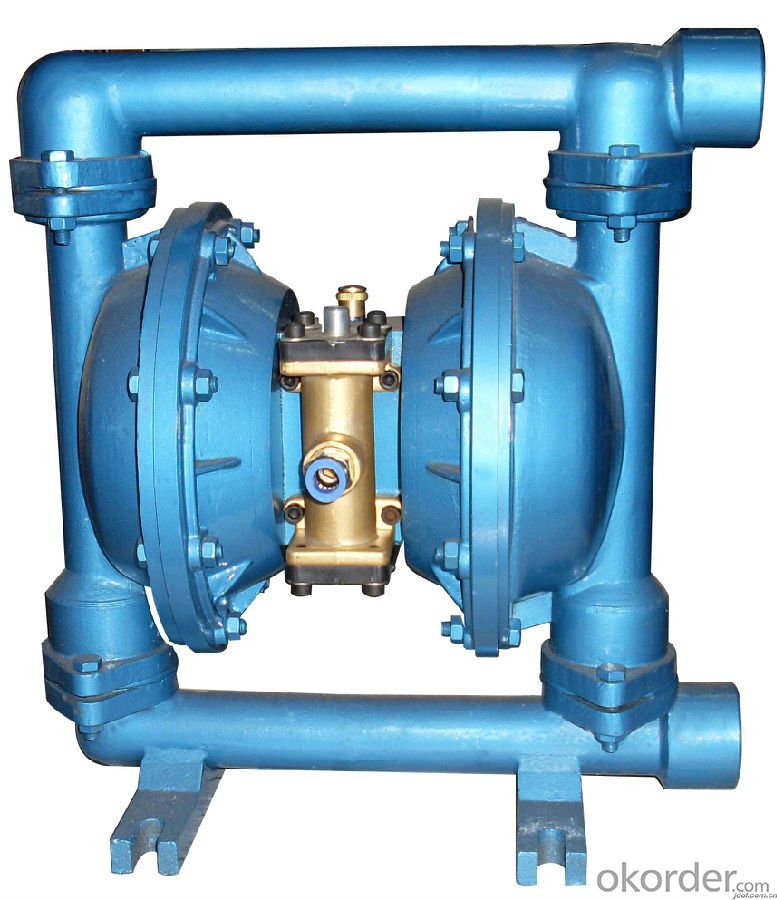

Air Operated Double Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Air operated double diaphragm pump Product description

QBY air operated double diaphragm pumps not only can transfer the flow liquid, but also can transfer some uneasy flowed medium, with the merits of self-priming pump,diving pump, shield pump, slurry pump and impurity pump etc.

1.It’s unnecessary to pour the drawing water, the suction lift reaches 7m height, the delivery lift reaches 70m length and the outlet pressure≥6kgf/cm²;

2.Wide flow and good performance. The diameter allowed to pass the max grain reaches 10mm. The damage is very less to the pump while exchausting the slurry and impurity.

3.The delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment (the pneumatic pressure adjustment is between 1-7kgf/cm²) ;

4.This pump has no rotary parts and no bearing seals. The diaphragm will completely separate the exhausted medium and pump running parts, working medium. The conveyed medium can’t be leaked outside. Thus it will notcause the environment pollution and human body safety danger while exhausting the toxin and flammable or corrsive medium.

5.No lectricity.It’s safe and reliable while using in the flammable and explore places.

6.It can be soaked in medium to work.

7.It’s convenient to use and reliable to work.Only open or close the gas valve body while starting or stopping. Even if no medium operation or pausing suddenly for long time because of accident matters,the pump will not be damaged caused by this. Once over-loading, the pump will auotomatically stop and possesses the selfprotection function. When the load recovers normally, it also can start automatically.

8.Simple structure and less wering parts. This pump is simple in structure, installation and maintance. The medium conveyed by the pump will not touch the matched pneumatic walve and coupling lever etc. Not like other kinds pumps, the performance will drop down.

9.Gradually because of the damages of rotor, gear and vane etc.

10.This pump needn’t the oil lubricant. Even if idling, it has influence to the pump.This is a special characteristic of this pump.

Air operated double diaphragm pump Application

1.The pump can suck the peanut, pickles, tomato slurry, red sausage, chocolate, hops and syrup etc.

2.The pump can suck the paint,pigment,glue and adhesive etc.

3.The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

4.The pump can suck variousgrinding materials, corrosive agent and clean the oil dirt etc.

5.The pump can suck various toxin and flammable or volatility liquid etc.

6.The pump can suck various wedge water,cement sllurry and mortar etc.

7.The pump can suck various strong acid, alkali and corrosive liquid etc.

8.It can be used as a front-step transmission device of the solid and liquid separation equipment.

Air operated double diaphragm pump Technical Data:

Flow rate: up to 30 m³/h

Head: up to 50 m

Speed: max 2900 rpm

Temperature: max 105 °C

Casing pressure: up to MPa

Shaft seal: mechanical sealing

- Q: Are there any specific maintenance tips for prolonging the lifespan of an air pump?

- Yes, there are a few specific maintenance tips for prolonging the lifespan of an air pump. Firstly, it is important to regularly clean the air filter to prevent dust and debris from clogging the pump. Secondly, ensure that the pump is placed on a stable and level surface, as vibrations can cause damage over time. Additionally, it is recommended to lubricate the moving parts of the pump as per the manufacturer's instructions to reduce friction and prolong its lifespan. Finally, avoid overworking the pump by using it within its recommended capacity and avoid exposing it to extreme temperatures or moisture.

- Q: Are air pumps suitable for inflating air mattresses with adjustable heights?

- Yes, air pumps are suitable for inflating air mattresses with adjustable heights. Air pumps are designed to quickly and efficiently inflate air mattresses of various sizes and heights. They typically come with different nozzle attachments that can accommodate different valve types and sizes, making them versatile enough to handle mattresses with adjustable heights. Additionally, air pumps often have adjustable pressure settings, allowing you to control the firmness and height of the mattress. Overall, using an air pump is a convenient and practical solution for inflating air mattresses with adjustable heights.

- Q: What kind of fish can live without inserting oxygen pumps?

- Cold water fish, such as fish, tropical fish in Manlong, large fish kissing, and some varieties, will be a breath of air, the extraction of oxygen from,

- Q: My cylinder is smaller.. It's probably only the size of the volleyball.. Two goldfish were kept.... A few days before the first floating phenomenon.. I bought an oxygen pump.. But I don't know whether to open it for 24 hours.. Do you have an oxygen pump?I want to ask you a question.. That's the fake flower I put in my tank.. But fake flowers make up a pretty large area of the fish bowl.. Does it have any effect on fish? It feels nice to put on and never let go.. Think the fish tank is empty

- The false grass can affect the activity space of fish, so it is better to change the proportion of fish. The switch of the oxygen pump is related to the quantity and environment of the fish. If the fish is more or larger (according to the proportion of the tank fish), you need to open, the weather is bad, ventilation is not good, the water quality is bad, you also need to open. Electricity consumption and pump power related, the pump is generally marked with power rating, 1 kilowatt hour only once, in fact, not much.

- Q: What are the noise levels of different air pump models?

- The noise levels of various air pump models can differ greatly depending on the particular brand and model. Certain air pumps might create minimal noise, which is hardly noticeable to the human ear, whereas others might generate a moderate amount of noise that is still bearable. Nevertheless, there are also air pumps that can be quite noisy, emitting a distinct humming or buzzing sound. It is important to keep in mind that noise levels can also be affected by factors such as the overall quality of the air pump, the type of motor utilized, and the installation environment. Therefore, it is advisable to conduct research, read customer reviews, or seek advice from experts to ascertain the noise levels of specific air pump models prior to making a purchase.

- Q: Can an air pump be used for inflatable team mascots?

- Indeed, inflatable team mascots can certainly utilize an air pump. Typically crafted from sturdy materials like nylon or PVC, these mascots possess valves or openings that can be linked to an air pump. By employing said air pump, one can effortlessly infuse the mascot with air, bringing it to life and establishing a captivating presence for one's team. It is imperative to select an air pump that aligns with the dimensions and nature of the inflatable mascot possessed, guaranteeing swift and effective inflation.

- Q: Can an air pump be used for inflatable water mat platforms?

- An inflatable water mat platform can indeed utilize an air pump. Generally, inflating such water mats necessitates the use of an air pump. Its purpose is to swiftly and effortlessly fill the mat with air, enabling it to float atop the water. The pump typically includes multiple nozzle attachments to accommodate various valve types on the mat. By employing an air pump, you can guarantee the proper inflation of your water mat, ensuring it is swiftly prepared for use.

- Q: Can an air pump be used for inflatable advertising arches?

- Certainly, inflatable advertising arches can absolutely utilize an air pump. In reality, the utilization of an air pump is the prevailing and optimal approach for inflating these particular structures. An air pump ensures a consistent stream of air into the arch, facilitating a swift and effortless inflation process to achieve the desired shape and size. Furthermore, an air pump is also applicable for deflating the arch when it necessitates storage or transportation. In summary, an air pump is an indispensable instrument for effectively managing and employing inflatable advertising arches.

- Q: When the air pump starts, it seems that there is not enough strength, so the rhythm is very slow, and then it does not turn. It seems to be the owner of the card. That's the case. Thank you very much for the help of experienced people..

- Check that the drive shaft is in good condition.

- Q: What is the recommended air flow rate for a fish tank air pump?

- The recommended air flow rate for a fish tank air pump depends on several factors such as the size of the tank, the number of fish, and the specific needs of the fish species. As a general guideline, it is recommended to have an air flow rate of 0.5 to 1 gallon of air per hour for every gallon of water in the tank. This helps to maintain proper oxygen levels in the water, which is essential for the health and well-being of the fish. However, it is important to consider the specific requirements of your fish species, as some may require higher or lower oxygen levels. Additionally, factors such as the presence of live plants or aeration devices in the tank may also influence the recommended air flow rate. Therefore, it is best to consult with a knowledgeable aquarium specialist or refer to the specific recommendations provided by the manufacturer of your air pump to determine the most suitable air flow rate for your fish tank.

Send your message to us

Air Operated Double Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords