Aluminum Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

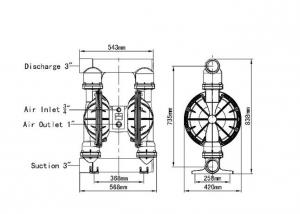

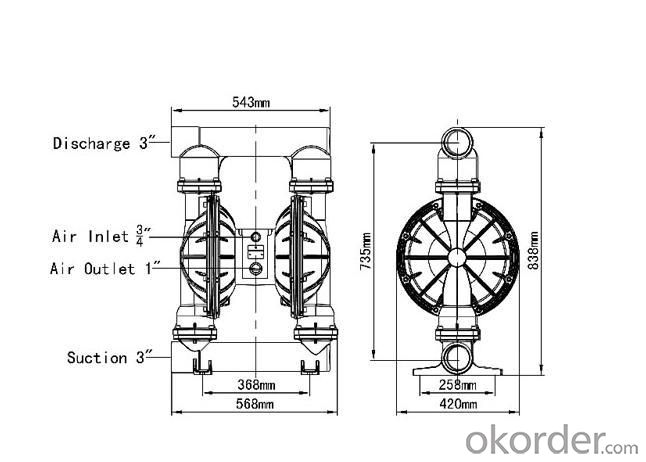

Details for Aluminum Diaphram Pump

1, Package and delivery of Aluminum Diaphram Pump

1) Packed with standard exporting wooden case, requested package will be acceptable.

2) Delivery date will be within 30 days after receiving the prepayment.

2, Technical specification of Aluminum Diaphram Pump

1) Connector type:2”.3”

2) Casing material:Aluminum alloy and stainless steel.

3) Max pressure psi(bar):100(6.9).

4) Max diameter of Suspended solid in(mm): 1/4" (6.4) PP20A; 3/8" (9.5) PP30A.

3, Model and specs details of Aluminum Diaphragm Pump.

|

|

PDP-8 |

PDP-10/15 |

PDP-20/25 |

PDP-25A |

PDP-32/40 |

PDP-50/65 |

PDP-80/100 |

PDP-125 |

|

Caliber ( mm) |

8 |

10/15 |

20/25 |

25 |

32/40 |

50/65 |

80/100 |

125 |

|

Fluid flow ( m³/h) |

0~1 |

0~1 |

0~3 |

0~7 |

0~9 |

0~21 |

0~34 |

0~60 |

|

Pressure ( bar) |

7 |

7 |

7 |

8.4 |

8.4 |

8.4 |

8.4 |

8.4 |

|

Head ( m) |

50 |

50 |

70 |

70 |

70 |

70 |

70 |

70 |

|

MAX. air consumption ( scfm) |

9.0 |

9.0 |

28 |

60 |

60 |

125 |

175 |

325 |

4, The advantages about our Powder Diaphram Pump

1) Four bolts connection with very round ball, well seal and good dry suction. The actual dry suction can reach to 4~7m.

2) High roundness valve ball for use the ball mill machine.

3) Three section manifold, Flexible installation and even can simultaneously convey two different liquids.

4) Longer diaphragm life. Diaphragm material from Dopont, Exxon.

5) Pilot type air valve, low maintenance, low air consumption, so the using cost is low.

6) Wetted body: PPH, PVDF, SS304, SS316, Aluminum etc.

7) Diaphragm: PTFE, Hytrel, Santoprene, Viton etc.

- Q: What is the recommended air pressure for inflatable pool floats?

- The recommended air pressure for inflatable pool floats typically ranges between 1.5 to 2.5 pounds per square inch (psi).

- Q: How do you use the air pump to inflate the battery tires?

- Can only be connected to a battery positive and negative 12V, can only be connected to a battery positive and negative pole, pay attention to is a piece

- Q: Can an air pump be used for inflatable holiday yard decorations?

- Yes, an air pump can be used for inflatable holiday yard decorations. In fact, it is highly recommended to use an air pump for inflating these decorations as it makes the process much easier and faster. Air pumps are designed to provide a steady flow of air, which is essential for inflating large and complex inflatable decorations such as those used during the holiday season. They come in different sizes and types, including manual and electric pumps, so you can choose the one that best suits your needs. Using an air pump ensures that your inflatable holiday yard decorations are properly inflated and ready to be displayed in no time.

- Q: Are air pumps suitable for inflating air mattresses for home use?

- Yes, air pumps are suitable for inflating air mattresses for home use. Air pumps are designed specifically for inflating various inflatable items, including air mattresses. They are efficient, easy to use, and provide a quick and convenient way to inflate your air mattress. Additionally, air pumps often come with different nozzle attachments, allowing you to find the right size for your air mattress valve. This ensures a tight seal and prevents any air leakage during the inflation process. Whether you have an indoor or outdoor air mattress, using an air pump is a practical and reliable method to inflate it for home use.

- Q: Air pump has been installed oil-water separator, in the process of spraying, there are small dots, how to do?

- 1, do you use an oil pump or an oil-free air pump?;2, the ordinary oil-water separator can only remove part of the oil or water;Terms of settlement:1, choose oil-free gas pump;2, replace a good oil-water separator;3, the daily maintenance of the air pump needs to be done. The gas tank is regularly drained

- Q: How long does an air pump take to deflate an inflatable object?

- The length of time it takes for an air pump to deflate an inflatable object can vary depending on several factors. The size and volume of the object, the power and efficiency of the air pump, and the pressure of the air inside the inflatable can all play a role in the deflation process. Generally, a standard air pump can deflate a small to medium-sized inflatable object within a few minutes. However, larger or more complex inflatables may take longer, potentially up to 10-15 minutes or even more. Additionally, the rate at which the air is released from the inflatable can also affect the deflation time. Some air pumps have adjustable settings or different nozzles that control the airflow, allowing for faster or slower deflation. It's worth noting that manually deflating an inflatable object using an air pump may take longer than using an electric or high-powered pump. The method chosen to deflate the object will also impact the time it takes. Ultimately, the specific circumstances and equipment used will determine the exact duration it takes for an air pump to deflate an inflatable object.

- Q: Can an air pump be used for inflating air curtains for windows?

- No, an air pump is not typically used for inflating air curtains for windows. Air curtains are usually inflated using a blower or a fan that is specifically designed for this purpose.

- Q: Can an air pump be used for inflating air mattresses with plush tops?

- Yes, an air pump can be used for inflating air mattresses with plush tops. However, it is important to ensure that the air pump is compatible with the valve on the air mattress. Some air mattresses have specific valve types that require specific pumps or adapters. It is recommended to check the manufacturer's instructions or guidelines to determine the appropriate pump for the specific air mattress. Using the wrong pump or applying too much pressure could potentially damage the mattress or affect its performance.

- Q: How to install an air pump in an aquarium?

- To install an air pump in an aquarium, follow these steps: 1. Choose a suitable air pump based on the size of your aquarium and the number of air outlets needed. 2. Place the air pump in a dry and elevated location near the aquarium. 3. Attach an air tubing to the outlet of the air pump and connect the other end to an air stone or air diffuser. 4. Position the air stone or diffuser in the desired location within the aquarium. 5. Plug in the air pump to a power source and ensure it is securely connected. 6. Adjust the airflow using the control valve, if applicable, to achieve the desired level of aeration. 7. Regularly maintain and clean the air pump to ensure optimal performance and longevity.

- Q: Can an air pump be used for bouncy castles or inflatable toys?

- Yes, an air pump can be used for bouncy castles or inflatable toys. In fact, it is the most common and efficient way to inflate them. An air pump provides a steady stream of air that can quickly and easily fill up the inflatable structure. It is designed specifically for this purpose, with the right amount of pressure and nozzle attachments to fit the valves of bouncy castles and inflatable toys. Using an air pump ensures a safe and proper inflation, making the bouncy castle or inflatable toy ready for use in no time.

Send your message to us

Aluminum Diaphragm Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit unit

- Supply Capability:

- 1000 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords