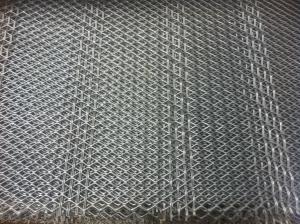

316 Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q: How to calculate the maximum bending stress of steel pipe? Is there a list of the maximum flexural normal stresses for steel pipes of different materials and diameters?

- Strength design of steel pipe by this formula to calculate the maximum normal stress in the steel pipe should be less than the value (based on your choice of different grades of steel, steel strength design value is not the same, this value can also be found through the design manual of steel structure), meet the requirements, it can meet the requirements of steel pipe under the action of bending moment strength.

- Q: What is the maximum length of steel pipes available in the market?

- The maximum length of steel pipes available in the market can vary depending on various factors such as the type of steel, manufacturing capabilities, transportation limitations, and customer requirements. However, in general, steel pipes can be manufactured in lengths of up to 12 meters (40 feet) or even longer. It is important to note that longer lengths may be more challenging to handle and transport, and may require specialized equipment or techniques. Ultimately, the maximum length of steel pipes available in the market will be determined by the specific needs and capabilities of the industry and customers.

- Q: How does the price of steel pipes vary based on market demand?

- The price of steel pipes can vary based on market demand as it follows the basic economic principle of supply and demand. When the demand for steel pipes is high and the supply is limited, the price tends to increase. Conversely, when the demand is low and there is excess supply, the price tends to decrease. Factors such as infrastructure projects, industrial growth, and construction activities heavily influence the demand for steel pipes, thus impacting their price in the market.

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are commonly used in the manufacturing of food processing machinery and equipment due to their durability, corrosion resistance, and high strength. These pipes are used for various purposes such as fluid transportation, steam generation, and structural support in the machinery. They are also crucial for conveying liquids, gases, and other food ingredients safely and hygienically throughout the manufacturing process. Additionally, steel pipes can withstand high temperatures and pressures, making them ideal for applications like sterilization, pasteurization, and cooking in food processing machinery.

- Q: What are the potential health hazards associated with steel pipe installation?

- Some potential health hazards associated with steel pipe installation include exposure to hazardous chemicals used in the coating or treatment of the pipes, inhalation of dust or fumes generated during cutting or welding, and physical injuries due to accidents or mishandling of heavy equipment. Additionally, improper handling or disposal of waste materials and contaminated water can pose environmental health risks. It is important to follow proper safety protocols, use personal protective equipment, and ensure proper ventilation and waste management to mitigate these hazards.

- Q: What is the cost of steel pipes compared to other piping materials?

- The cost of steel pipes can vary depending on factors such as size, thickness, and grade. However, generally speaking, steel pipes tend to be more expensive than other piping materials such as PVC or copper. This is due to the durability, strength, and longevity of steel pipes, making them a preferred choice for various industrial and construction applications.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes can be used for oil refineries. Steel pipes are commonly used in oil refineries due to their high strength, durability, and resistance to corrosion. They can handle the high pressure and temperature requirements of the oil refining process, making them suitable for transporting and distributing various petroleum products within the refinery.

- Q: What is the difference between seamless steel pipes and seamless alloy steel pipes?

- The main difference between seamless steel pipes and seamless alloy steel pipes lies in their composition. Seamless steel pipes are made from carbon steel, while seamless alloy steel pipes are made from various alloying elements such as chromium, nickel, or molybdenum. These alloying elements enhance the properties of the steel, making it more resistant to corrosion, higher in strength, and suitable for specific applications in industries like oil and gas, chemical, or power generation.

- Q: How are steel pipes repaired if they develop leaks?

- Steel pipes can be repaired if they develop leaks through various methods such as welding, clamping, or using epoxy compounds. The specific repair technique depends on the size and location of the leak as well as the type of pipe, and it is typically carried out by trained professionals with the necessary equipment and expertise.

- Q: What are the different pipe fittings used with steel pipes?

- Some common pipe fittings used with steel pipes include couplings, elbows, tees, unions, reducers, and caps.

Send your message to us

316 Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords