3004 Composited Aluminum Shiny Sheet Aluminum Plate - Aluminum Skin Sheets Greenville Sc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

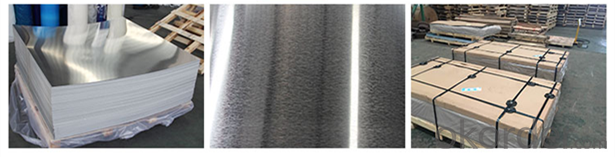

Product | Aluminum Plate |

Property | Anti-Corrosion,Heat Resistant |

Surface | Mill Finish |

Production Process | Cold Rolled,Hot Rolled |

Temper | O,H14,H24,H32,H112 Etc;T4,T651 Etc |

Thickness | 0.3mm - 300mm |

Width | 100mm - 2600mm |

Length | 1000mm - 12000mm |

MOQ | 7 tons(According to specifications) |

Payment Term | TT,LC at sight,WestUnion,KunLun Bank |

Package | Export wooden pallets,Craft paper,Anti-Blushing Agent. |

Delivery Time | Future goods:20-30 Work days,Ready Stock:7-10 days. |

Quality of Material | Totally free from defects like white rust,adge damage,camber,dents,holes,break lines,scratches . |

Kind Attention | Specification can be custommized as the customer's requirements. |

Quality Inspection

Product Description

Why we choose Okorder.com?

Okorder.com is a professional and reliable online E-market place

Providing a variety of products with reasonable prices

High quality goods provided by factory suppliers

Shipping to over 200 countries.

One-stop sourcing

Dubai Logistic Complex

Okorder Quality Control?

We hold a very strict quality control system to check every connector of our products for your safety.

Okorder services for you

1.7*24 hours Hotline & Email Service

2. Your inquiry related to our products or prices will be replied in 24hrs.

3. Well-trained and experienced staffs to answer all your enquires in fluent English

4. OEM&ODM, any your customized demand we can help you to design and put into product.

5. Distributor ship are offered for your unique design and some our current models

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal material for manufacturing aircraft structures, such as fuselages, wings, and structural components. Additionally, aluminum can be easily machined and formed into complex shapes, allowing for the production of lightweight and aerodynamic structures. Furthermore, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the structural integrity of aerospace components. Overall, aluminum sheets are well-suited for aerospace applications and have been extensively utilized in the industry for many years.

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- For okorder /

- Q: A 15.1 g aluminum block is warmed to 53.2 °C and plunged into an insulated beakercontaining 32.6 g of water initially at 24.4 °C. The aluminum and the water are allowed to cometo thermal equilibrium.Assuming that no heat is lost, what is the final temperature of the water and aluminum?

- To solve this problem, you need the heat capacity of water and Al, I know off hand the heat capacity of water but you'll need to look it up for Al. From the problem, you know that the heat given up as the aluminum cools is gained by the water heating up. As there is no phase change, the heat gained (or lost) is mass * heat capacity * temperature change energy gained by water = energy lost by Al. Let Tf be the final temperature of the Al and water. 32.6 g * 4.18 J/gK * (Tf - 24.4C) = 15.1 g * heat capacity of Al * (53.2 C - Tf) Solve for Tf. Because there is almost twice as much water as Al and water has a higher heat capacity than Al, the temperature will be closer to 24.4C than it is to 53.2C

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

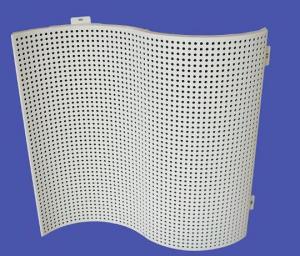

- Q: Can aluminum sheets be easily shaped or bent?

- Indeed, aluminum sheets possess a remarkable capability to be effortlessly molded or flexed. Renowned for its exceptional malleability and ductility, aluminum exhibits a remarkable propensity to be readily fashioned into diverse contours and curves. The manipulation of this versatile metal can be accomplished through an assortment of techniques, encompassing rolling, pressing, and even manual utilization of tools. Given its pliability, aluminum emerges as the preferred choice within industries such as automotive, aerospace, and construction, wherein the fabrication of intricate shapes and bends is a common necessity. Moreover, the lightweight nature and inherent resistance to corrosion further enhance aluminum's suitability for shaping and bending endeavors.

- Q: Explain how the use of aluminum sheets can impact the energy efficiency of a building.

- <p>Aluminum sheets can significantly affect a building's energy efficiency due to their excellent thermal conductivity and reflective properties. They can be used in building construction to form a barrier against heat transfer, reducing the need for heating and cooling. Additionally, aluminum's reflective surface can help in reflecting sunlight, thereby reducing heat gain in the building. However, if not properly insulated, aluminum's high conductivity can lead to heat loss, reducing energy efficiency. Therefore, the use of aluminum sheets in buildings often requires a balance between their heat-reflective and heat-conductive properties to optimize energy efficiency.</p>

- Q: What is the flexural modulus of aluminum sheets?

- The measure of the stiffness or rigidity of aluminum sheets when subjected to bending or flexural stress is referred to as the flexural modulus. This mechanical property quantifies the aluminum sheet's resistance to deformation under applied force. Typically ranging between 69 GPa to 79 GPa, the flexural modulus of aluminum sheets depends on the specific alloy and temper. However, it is crucial to note that factors such as thickness, heat treatment, and manufacturing processes can cause slight variations in the flexural modulus. Aluminum is widely recognized for its exceptional strength-to-weight ratio, making it a favored choice for applications that require lightweight and durable materials. Due to its relatively high flexural modulus, aluminum sheets can maintain their shape and resist bending or flexing, making them suitable for uses in aircraft structures, automotive components, and building construction. It is important to highlight that the flexural modulus of aluminum can be improved through alloying elements or heat treatment processes. For instance, certain aluminum alloys like 7075 or 2024 may exhibit higher flexural modulus values due to their enhanced strength and stiffness properties. To summarize, the flexural modulus of aluminum sheets is a crucial mechanical property that determines their ability to withstand bending or flexural stress. This property provides valuable insights into the material's rigidity and assists engineers and designers in selecting the appropriate aluminum alloy and thickness for various applications.

- Q: Hello,Does it matter what kind of wheel I use as a cut off wheel on an angle grinder when cutting aluminum?Thanks!

- Yes but its for general purpose straight cuts. I've been using a Metabo cutting wheel in lieu of a torch for cutting,including stainless that's 3/16 or less. They work great, are inexpensive, and fit angle grinders.

- Q: What are the benefits of using aluminum sheets?

- Using aluminum sheets in various applications offers several advantages. Firstly, aluminum sheets are lightweight, which makes them easy to handle and transport. This is particularly beneficial in industries like aerospace, automotive, and construction, where reducing weight is crucial for better fuel efficiency and overall performance. Secondly, aluminum sheets provide excellent resistance to corrosion. Unlike other metals, aluminum naturally develops a protective oxide layer when exposed to air, preventing further corrosion and enhancing durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another advantage of aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight yet sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can easily be formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is completely recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to primary aluminum production, resulting in reduced carbon emissions and a smaller environmental footprint. Lastly, aluminum sheets exhibit excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. In conclusion, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

Send your message to us

3004 Composited Aluminum Shiny Sheet Aluminum Plate - Aluminum Skin Sheets Greenville Sc

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords