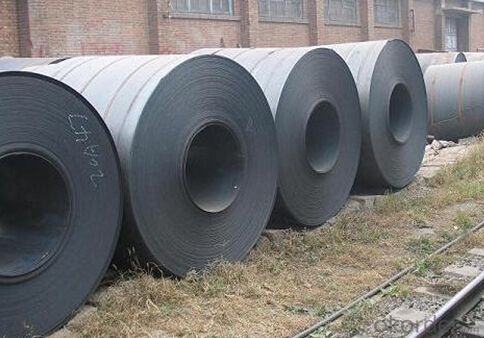

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

Quick Details

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Standard | Grade | General Size | Delivery Condition |

ASTM A36 | A36/A36-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A283 | A283-B/A283C | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A572 | A572Gr50-B/A572Gr42-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A515 | A515Gr70 | 5-20 * 2300-2500 * C | Black Condition |

ASTM A516 | A516Gr70 | 5-20 * 2300-2500 * C | Black Condition |

JIS G 3101 | SS400-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

JIS G3136 | SN400B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

EN10025-2:2004 | S235JR-S355K2+N | 5-20 * 2300-2500 * C | Boron added or Black Condition |

EN10025-5:2004 | S355J2W/S355K2W | 5-20 * 2300-2500 * C | Black Condition |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the properties of high-temperature tool steel?

- High-temperature tool steel is known for its exceptional heat resistance, hardness, and wear resistance. It has the ability to retain its strength even at elevated temperatures, making it ideal for applications in high-temperature environments. Additionally, it exhibits excellent toughness, allowing it to withstand heavy loads and resist deformation. High-temperature tool steel also has good dimensional stability and can maintain its shape even under extreme conditions.

- Q: What are the different methods for improving the tensile strength of special steel?

- There are several methods for improving the tensile strength of special steel, including heat treatment, alloying, cold working, and grain refinement. Heat treatment involves heating the steel to a specific temperature and then rapidly cooling it, which can result in increased strength. Alloying refers to adding specific elements such as chromium, nickel, or molybdenum to the steel, which can enhance its strength properties. Cold working involves subjecting the steel to mechanical deformation at low temperatures, which can increase its strength. Grain refinement, on the other hand, involves controlling the size and distribution of the steel's crystalline structure, leading to improved strength.

- Q: Can special steel be used for making mining equipment?

- Yes, special steel can be used for making mining equipment. Special steel, such as high-strength and wear-resistant alloys, is commonly utilized in the manufacturing of mining equipment due to its durability and ability to withstand harsh mining conditions. It offers superior resistance to abrasion, impact, and corrosion, making it suitable for applications like excavators, drill bits, crushers, and other machinery used in the mining industry.

- Q: What are the applications of special steel in the oil and gas manufacturing process?

- Special steel is widely used in the oil and gas manufacturing process for various applications. It is utilized in the construction of pipelines, offshore platforms, and equipment such as valves, pumps, and compressors. The high strength and corrosion resistance of special steel make it suitable for handling extreme conditions, such as high pressure and temperature environments, as well as corrosive substances like drilling fluids and sour gases. Additionally, special steel is employed in the fabrication of storage tanks and vessels, ensuring durability and preventing leakage or failure. Overall, the applications of special steel in the oil and gas industry contribute to enhanced safety, efficiency, and longevity of the manufacturing process.

- Q: What are the future trends in special steel manufacturing?

- The future trends in special steel manufacturing are likely to focus on advancements in technology, sustainability, and the development of new alloys. Firstly, technology will play a significant role in shaping the future of special steel manufacturing. Automation and robotics are expected to be increasingly integrated into the production process, leading to improved efficiency, precision, and reduced labor costs. This will also allow for better quality control and the ability to produce more complex and customized steel products. Secondly, sustainability will be a key focus in special steel manufacturing. As the world becomes more environmentally conscious, companies are seeking ways to reduce their carbon footprint. This includes employing cleaner production methods, such as using renewable energy sources and implementing recycling programs to minimize waste. Additionally, there will likely be a shift towards developing greener alloys with reduced environmental impact. Furthermore, the development of new alloys will be crucial in meeting the evolving needs of various industries. With advancements in material science, special steel manufacturers will be able to create alloys with enhanced properties, such as increased strength, durability, corrosion resistance, and heat resistance. These new alloys will cater to the growing demand for high-performance materials in sectors like aerospace, automotive, energy, and construction. Moreover, the future of special steel manufacturing is also likely to be influenced by the increasing demand for lightweight materials. As industries strive to improve fuel efficiency and reduce emissions, there will be a need for special steel alloys that offer high strength-to-weight ratios. This will drive research and development efforts towards creating lighter yet stronger steel products. In conclusion, the future trends in special steel manufacturing will revolve around technological advancements, sustainability, and the development of new alloys. These trends will shape the industry, bringing about increased automation, cleaner production methods, and the creation of innovative alloys to meet the changing needs of various sectors.

- Q: How does special steel contribute to sustainable construction?

- Special steel contributes to sustainable construction in several ways. Firstly, it has high strength and durability, which allows for the design and construction of lighter and more efficient structures. This reduces the amount of material needed and saves resources. Secondly, special steel is often made from recycled materials, reducing the demand for virgin resources and minimizing environmental impact. Additionally, special steel can be easily recycled at the end of its life cycle, promoting a circular economy and reducing waste. Overall, special steel helps to create sustainable buildings by improving energy efficiency, reducing carbon emissions, and conserving resources.

- Q: How is special steel used in the marine supply chain?

- Special steel is used extensively in the marine supply chain due to its exceptional strength, corrosion resistance, and durability. It is utilized in the construction of various marine components such as ship hulls, propeller shafts, offshore platforms, and marine equipment. Special steel ensures the structural integrity and longevity of these critical marine structures, enabling safe and efficient operations in harsh and corrosive marine environments.

- Q: What are the different coating options available for special steel?

- Some of the different coating options available for special steel include galvanizing, powder coating, electroplating, and organic coatings such as epoxy or polyurethane. These coatings provide protection against corrosion, enhance durability, and improve the aesthetics of the steel.

- Q: What are the different shot blasting techniques used for special steel?

- Some of the different shot blasting techniques used for special steel include wheel blasting, air blasting, and tumble blasting. Wheel blasting uses a high-speed rotating wheel to propel abrasive particles at the steel surface, while air blasting involves using compressed air to propel the particles. Tumble blasting, on the other hand, involves placing the steel in a rotating drum and allowing the abrasive particles to impact the surface as the drum rotates. These techniques help to remove surface contaminants, improve surface finish, and enhance the overall quality of the special steel.

- Q: What are the common alloying elements in special steel?

- The common alloying elements in special steel are chromium, manganese, molybdenum, nickel, and vanadium.

Send your message to us

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords