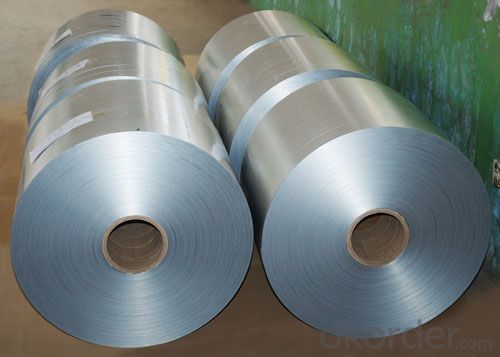

Acrylic Brand Aluminum Coil - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2a12 5052 5083 6061 6083 7075 Aluminum Sheet

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: Can aluminum coils be used for HVAC systems?

- Indeed, HVAC systems can utilize aluminum coils. Aluminum coils are frequently employed in HVAC systems due to their numerous advantages over alternative coil materials. To begin with, aluminum is a lightweight substance, facilitating easier handling and installation. Consequently, this can lead to decreased installation costs and diminished strain on the HVAC system's structure. Furthermore, aluminum coils possess exceptional heat transfer properties. They proficiently transfer heat from the refrigerant to the surrounding air, a critical aspect for the efficient operation of the HVAC system. Additionally, aluminum coils demonstrate a high resistance to corrosion, a quality of particular significance in environments with high humidity or pollutant levels. Moreover, aluminum stands as an immensely recyclable material, rendering it an environmentally conscious choice for HVAC systems. It can be effortlessly recycled and reused, thereby reducing the necessity for extracting new materials and minimizing waste generation. To summarize, aluminum coils represent a reliable and efficient selection for HVAC systems, offering remarkable heat transfer capabilities, durability, and environmental sustainability.

- Q: How much is the 25mm aluminum coil at current market?

- You must mean 25-wide aluminum coil. The price consists of the aluminum ingot price and processing charges. For example, if the processing price is 4500 yuan, it is relatively cheap. 25mm-wide aluminum coil is very narrow, so it will be much complicated to strip.

- Q: How much fluorocarbon and polyester paint should be used in production of aluminum coil and aluminum-plastic panel?

- The theoretical calculation is very complicated and far from actual result. In general, the manufacturer knows how much area and how thick their products can be painted.

- Q: What are the acoustic properties of buildings using aluminum coils?

- Buildings using aluminum coils for their acoustic properties can benefit from enhanced sound insulation and noise reduction. Aluminum coils have good sound absorption capabilities, helping to minimize the transmission of sound waves through walls, ceilings, and other surfaces. Additionally, the lightweight nature of aluminum coils allows for easy installation and can help reduce the overall weight of the building structure.

- Q: Are aluminum coils suitable for interior decorative applications?

- Yes, aluminum coils are suitable for interior decorative applications. Aluminum is a lightweight and versatile material that can be easily shaped into various forms, making it ideal for decorative purposes. It also comes in a wide range of finishes, colors, and patterns, allowing for endless design possibilities. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that it will maintain its aesthetic appeal over time. Moreover, aluminum is a sustainable material, as it can be recycled indefinitely, making it an environmentally friendly choice for interior decorations. Overall, aluminum coils provide a cost-effective and aesthetically pleasing option for interior decorative applications.

- Q: Can aluminum coils be utilized as materials for constructing roofs?

- <p>Yes, aluminum coils can be used for roofing materials. They are known for their durability, corrosion resistance, and lightweight properties, making them an excellent choice for roofing. Aluminum's reflective surface also helps in energy efficiency by reflecting sunlight and reducing heat absorption. It's recyclable and has a long lifespan, which contributes to its sustainability. However, it's important to ensure that the aluminum coils are of the appropriate gauge and quality for the specific roofing application to guarantee structural integrity and performance.</p>

- Q: What are the potential applications of recycled aluminum coils?

- Recycled aluminum coils have various potential applications across several industries. They can be used in the manufacturing of automotive parts, such as body panels, engine components, and heat exchangers. Additionally, they can be utilized in the production of building materials like roofing, gutters, and siding due to their corrosion resistance and durability. Moreover, recycled aluminum coils are suitable for packaging purposes, including beverage cans, food containers, and aerosol cans. Their versatility and sustainability make them an excellent choice for a wide range of applications.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

- Q: What type of equipment is used to process aluminum coils?

- The type of equipment commonly used to process aluminum coils includes slitters, cut-to-length lines, roll formers, and annealing furnaces.

- Q: How are aluminum coils manufactured to specific dimensions?

- Aluminum coils are manufactured to specific dimensions through a process known as rolling. In this process, large aluminum ingots are heated and then passed through a series of rolling mills, where they are gradually reduced in thickness and elongated. By adjusting the speed and pressure of the rolling mills, manufacturers can control the dimensions of the aluminum coils, ensuring they meet the required specifications.

Send your message to us

Acrylic Brand Aluminum Coil - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords