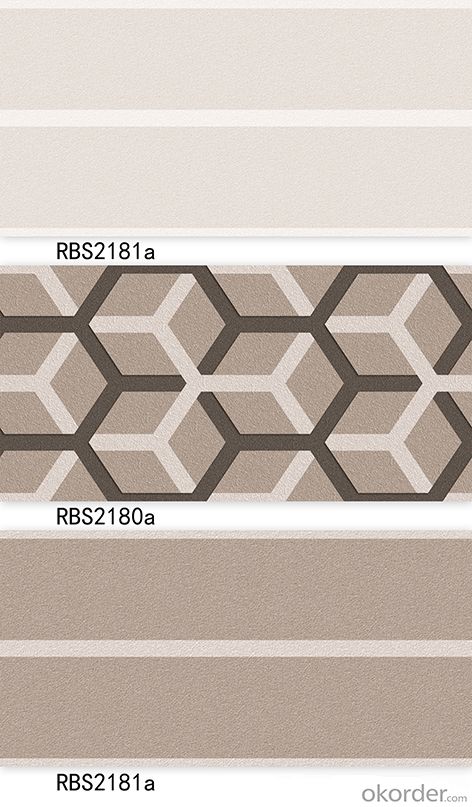

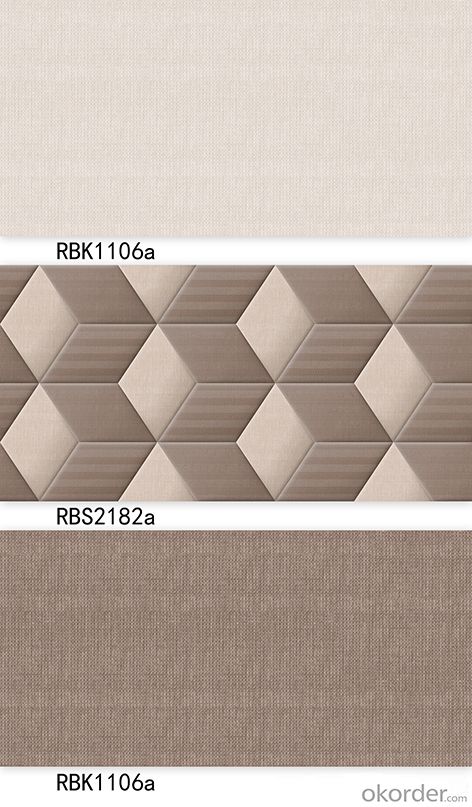

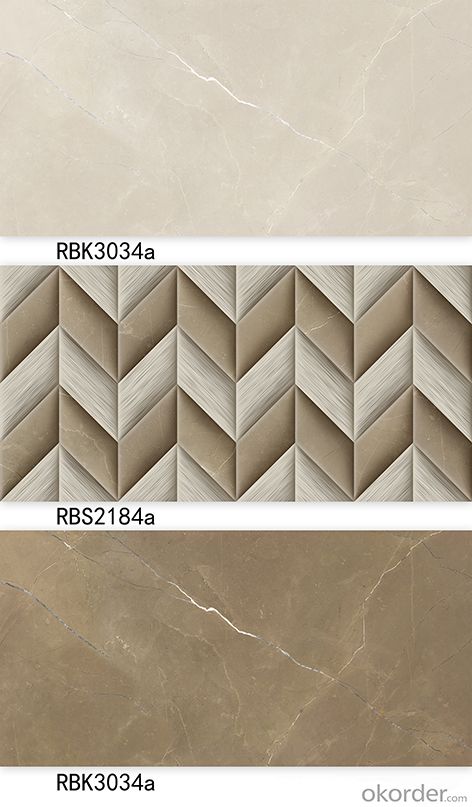

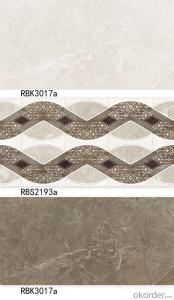

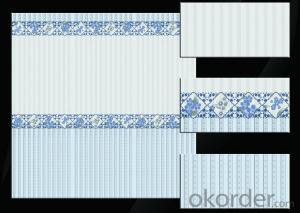

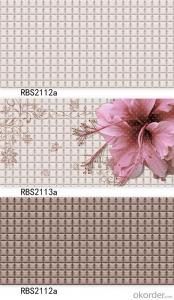

2016 New arrival interior ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ceramic wall tiles for bathroom & kitchen for Dubai market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

- Q: I would like to remove my carpet and get a nice tough wood flooring.

- The most durable - tough flooring is either maple or oak - very durable - in terms of engineered flooring - I just put in a composite flooring that had a 1/8 thick hardwood veneer on a plywood base - prefinished. It went in great. 7 wide x 84 long pieces - tongue and groove - Good luck

- Q: Solid wood floor teak or rosewood good

- Fourth NiudundouNiudundou also known as African teak, tree characteristics and distribution of Niudundou: large tree, 39m high, 1.5-1.8m diameter, trunk straight cylindrical, long 24m, grown in sandy soil in high rainfall areas, mainly in africa. Niudundou floor is formed by the African timber Niudundou of raw materials for the production of the floor, because the Newtown bean has good stability, and can be comparable to teak, also known as African teak.Niudundou wood properties: Wood gloss, no special taste; texture staggered, knot very fine and uniform; the wood is heavy to very heavy; dry shrinkage of medium to large, high strength. The air dry density is 0.81-1.01 (g/cm3). Wood drying properties unknown. Slightly resistant; resistant to termites, but are vulnerable to marine drilling wood animal damage; sapwood heartwood preservatives Baptist note medium difficulty, sawing, planing and other processing performance; no nail splitting, good nail holding ability. Suitable for flooring, furniture, etc..

- Q: How to choose wood flooring

- In the past the market once chaos marked name, name and fake hybrid between strange and eccentric, and what Watkins grapefruit, Jinbuhuan, rich wood, so that customers do not know true and false, good or bad. Therefore, the new standards must be strictly nominal, and in the form of appendix. Sales should be issued by the authority of the test report shall prevail.

- Q: Shop a few years of the floor, was not a sound, and now a few steps up the sound, there is no relatively simple maintenance methods. Check Baidu, most of the answers to such questions in the post to talk about the principle of sound, as well as attention to the floor. The question now is not a new floor, so if your answer is similar, it will not trouble you. Others say that..

- Wooden keel distance too farWooden keel distance should not be too far.

- Q: I was thinking of installing a new engineered hardwood floor in my house. I fond a flooring suppler that is selling a brand named Green Bay by Heritage co. I was wondering if anyone has installed it in their house and if they liked it. Any comments are appreciated.Thanks in advance.

- I goggled Heritage Company and Green Bay hardwood floors and found no info on either pertaining to flooring.I've never heard of either myself. Maybe you could call a Lumber Liquidators store in your area,they are a major flooring wholesaler who might be able to give you some info.

- Q: Choice of solid wood flooring to pay attention to what, after the completion of the road to pay attention to how to maintain

- First, look at the moisture content of the floor. Moisture content is generally less than 14% is considered qualified products, see the floor of the processing accuracy of two. With two pieces of the floor together to see the seam tightness of three, see the floor of the paint finish degree of four, open the package to check when the board and the delivery of the specifications, colors, wood species are consistent. Five, look at the floor of the delivery has no shortcomings. If the surface of hole, hole, scar, obvious variant, a burst of paint is complete and smooth etc.. Six, the acceptance of installation materials. The plate is the best choice of Longhu board, because it does not contain formaldehyde, benzene and other harmful substances, and is waterproof, anti mildew, variant high density and very stable material! If you do use a splint or wooden plate, it must be dry, anti-corrosion, mildew, pest control treatment can be installed, or after installation in addition, variant will be moldy, careful splint splint unqualified formaldehyde exceed the standard, 70%. Note: seven, installed in the ground shall be flat, clean, laying a layer of moisture-proof cotton pad, then. If you use the dragon and tiger plate on the ground is very normal, you can not play too many nails, fixed directly installed floor. Attention to the installation of the floor, each plate to leave the 1-2MM seam, four sides to stay more than 1CM seam. Eight, acceptance of installation quality: look at the floor whether there is a sound, the overall level, there is no installation is not tight, or the existence of the paint off the board, look at the four sides and foot line interface and nail eye treatment

- Q: Solid wood floor is divided into all A board AB board, and so what is the difference between how to distinguish

- All A board and AB board, before leaving the factory, there is a pick inspection procedures, in accordance with the national standard GB15036-2009. Sub AA level a level B.

- Q: We are buying a house where the first floor will all be hand-brushed engineered hardwood flooring. I would like to find some kind of liner or guard that could potentially stick onto the floors directly (in the most aesthetically pleasing way) to protect it from spills of various kinds. We have a baby who is very likely to do all the spilling, so I'd prefer to avoid all the heartache proactively :) Is there a product out there that comes close to what I have in mind?

- Engineered flooring is pre finished and is usually not nailed in place. This makes it pretty much impossible to coat the floor with any additional protectant. About the best you can do is to use a rug of some kind in areas where spills are likely.

- Q: Which is the best wood floor and birch floor

- Advantages and disadvantages of Pan longan wood flooring.Birch flooring harder, not easy to impress

- Q: We are re doing our kitchen and living room floor and we would like to do wood flooring. We have a concrete slab so from what I have read we can't go with solid which was what we wanted but a few people have said engineered would be fine just wanted more opinions from any one who has done it or know more about it

- know dont think i have lol tc

Send your message to us

2016 New arrival interior ceramic wall tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches