Western Landscape and Geotextile 2024 Best Price High Quality HDPE Waterproofing Geomembrane Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

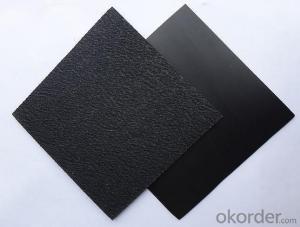

Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. It is mainly divided into LDPE geomembrane,LLDPE geomembrane , HDPE geomembrane, and all kinds of composite geomembrane.They are complete in specifications: double smooth surface, double rough surface and single rough surface.

Features: Excellent environment stress resistant cracking performance and chemical erosion resistance.

Big scope of application temperature and long service life.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Characteristics of filament geotextile

- It can replace the traditional engineering materials and construction methods, construction safer, and contribute to environmental protection, can be more economical, effective and lasting solution to the basic problems in the construction. Filament geotextile has good mechanical function, good water permeability, and can be anti-corrosion, anti-aging, with isolation, filtration, drainage, protection, stability, reinforcement and other functions, to adapt to uneven grass-roots, Damage, creep small, long-term load can still maintain the original function. Filament geotextile characteristics: strength - the same weight under the specifications, the tensile strength are higher than other acupuncture non-woven fabrics; anti-ultraviolet light - with high UV resistance; high temperature resistance - resistance High temperature up to 230 ℃, high temperature remains structural integrity and the original physical properties; permeability and flat drainage - geotextile thick and is needle-shaped, with good surface drainage and vertical permeability, years later Can maintain this performance; creep resistance - geotextile creep resistance is better than other geotextiles, so long effect is good. It can resist the erosion of common chemical substances in soil and resistance to gasoline, diesel and other corrosion; ductility - geotextile under a certain stress has a good elongation, so that it can adapt to uneven irregular base; Cloth technical features: thick geotextile, geotextile can guarantee the three-dimensional porosity, is conducive to the realization of excellent hydraulic performance. Geotextile break strength has a great advantage, especially for retaining walls and embankment reinforcement. Geotextile indicators are more than the national standard, is an excellent geotextile reinforced materials.

- Q: What are the considerations for geotextile selection in mining operations?

- When selecting geotextiles for mining operations, several considerations need to be taken into account. Firstly, the geotextile should be able to withstand the specific conditions of the mining site, such as high pressure, abrasion, and chemical exposure. It should also have sufficient strength and durability to support the load and prevent soil erosion. Additionally, the geotextile's permeability should be assessed to ensure proper drainage and filtration of water or other liquids. Lastly, its installation and maintenance requirements, as well as cost-effectiveness, should be considered to ensure seamless integration into the mining operation.

- Q: How do geotextiles contribute to soil reinforcement in embankments?

- Geotextiles contribute to soil reinforcement in embankments by providing a stable and reinforced base for the soil. They act as a barrier, preventing soil erosion and maintaining the integrity of the embankment. The geotextiles distribute the load across a wider area, reducing the stress on the soil and preventing settlement. Additionally, they enhance the overall stability of the embankment by increasing its resistance to lateral forces and promoting better drainage.

- Q: How do geotextiles affect soil nutrient availability?

- Geotextiles can enhance soil nutrient availability by promoting better water and air circulation, preventing soil erosion, and increasing organic matter content. This allows for improved nutrient uptake by plants and reduces nutrient leaching, ultimately leading to healthier and more fertile soils.

- Q: How are geotextiles tested for filtration efficiency?

- Geotextiles are tested for filtration efficiency using standardized laboratory tests, such as the ASTM D 4491 test method. This involves measuring the flow rate of water through the geotextile and analyzing the retention of particles of different sizes.

- Q: How do geotextiles aid in the protection of geomembranes?

- Geotextiles aid in the protection of geomembranes by acting as a protective barrier between the geomembrane and the surrounding soil or other materials. They prevent direct contact and potential damage from sharp objects, rocks, or roots, while allowing for the drainage of water and gases. This helps to extend the lifespan of the geomembrane and maintain its integrity, ensuring effective containment and protection in various applications such as landfills, ponds, or construction projects.

- Q: Reservoir dam waterproof geotextile cloth two bags of a large package should be how much money

- Do not understand, to answer what is the problem with ah, Google then you deleted, Google know the system do not know how ah

- Q: What are the different geotextile installation guidelines?

- Geotextile installation guidelines typically include steps such as site preparation, ensuring proper placement and alignment, securing the geotextile in place, and properly overlapping or joining adjacent sections. Additionally, specific guidelines may be provided for different applications, such as road construction, erosion control, or drainage systems, to ensure optimal performance and longevity of the geotextile.

Send your message to us

Western Landscape and Geotextile 2024 Best Price High Quality HDPE Waterproofing Geomembrane Liner

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords