201 Bright Annealing Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed information--Stainless Steel Pipe

| Description | stainless steel pipe, stainless steel tube |

| Type | 201,202,304,316,310,409,410,420,430,SAF2205,S31803 |

| Thickness | 0.25-10mm |

| Length | 3-6m or as customized |

| Outer diameter | 6-508mm |

size (round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or as customized |

| size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or as customized |

| size (oval pipe) | 30×15,80×40 mm or as customized |

| Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

| Finishing | Mill, Polished, Mirror, #600 |

Other information--Stainless Steel Pipe

| Certificate | BV, ISO, CE |

| Productivity | 800 tons/ day |

| Packing | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Stainless steel pipe can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

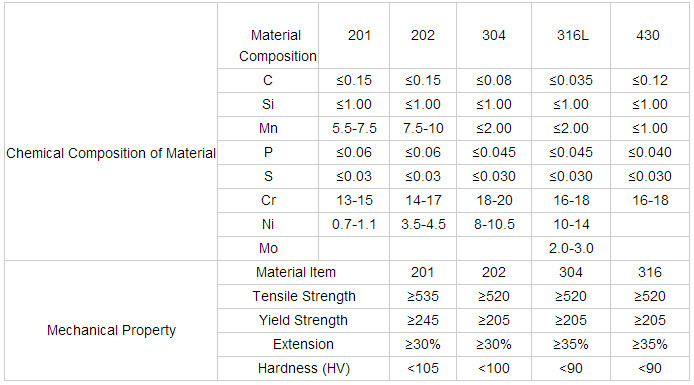

Chemical composition--Stainess Steel Pipe

- Q: What is the difference between 304H and 304 stainless steel pipes?

- The carbon content is what sets 304H stainless steel pipes apart from 304. Although both grades belong to the 304 stainless steel alloy, 304H has a higher carbon content than 304. This increased carbon content gives 304H pipes the ability to withstand higher temperatures, as they possess better strength and resistance against sensitization. Conversely, 304 stainless steel pipes are better suited for general applications due to their good corrosion resistance and widespread use in various industries. Consequently, when deciding between 304H and 304 stainless steel pipes, it is important to consider the specific requirements of the application, including the operating temperature and the need for enhanced strength and resistance against sensitization.

- Q: Are stainless steel pipes suitable for sewage treatment plants?

- Stainless steel pipes are indeed appropriate for sewage treatment plants. This is because stainless steel is an incredibly tough and corrosion-resistant material, which makes it well-suited for the harsh and corrosive conditions commonly found in sewage treatment plants. The material's superior resistance to corrosion prevents the pipes from deteriorating over time, ensuring a lengthier lifespan and reducing the necessity for frequent maintenance or replacements. Moreover, stainless steel pipes possess exceptional hygienic qualities, which are vital for sewage treatment plants to maintain proper sanitation. The smooth surface of these pipes prevents the accumulation of bacteria, biofilm, and other contaminants, making it easier to clean and sustain a high level of cleanliness. Additionally, stainless steel is environmentally friendly since it is entirely recyclable, thus contributing to sustainable practices in sewage treatment plants. In summary, stainless steel pipes are a dependable and suitable option for sewage treatment plants due to their durability, resistance to corrosion, hygienic properties, and eco-friendliness.

- Q: Can stainless steel pipes be used for drinking water supply?

- Yes, stainless steel pipes can be used for drinking water supply. Stainless steel is resistant to corrosion, making it a safe and reliable material for transporting drinking water. It does not leach harmful chemicals into the water and is highly durable, making it suitable for long-term use in water supply systems.

- Q: Can stainless steel pipes be insulated with cork?

- Yes, stainless steel pipes can be insulated with cork. Cork insulation is commonly used as it provides excellent thermal insulation properties, is resistant to moisture, and has good fire-retardant qualities. It can effectively reduce heat loss or gain in stainless steel pipes, making it a suitable choice for insulation.

- Q: Are stainless steel pipes suitable for liquid storage tanks?

- Yes, stainless steel pipes are suitable for liquid storage tanks. Stainless steel has excellent corrosion resistance properties, making it ideal for storing various liquids, including water, chemicals, and food products. The material is highly resistant to rust, oxidation, and staining, ensuring that the stored liquids remain uncontaminated. Stainless steel pipes also have high strength and durability, allowing them to withstand the pressure and weight of the stored liquids. Additionally, stainless steel is easy to clean and maintain, making it a reliable choice for liquid storage applications.

- Q: Can stainless steel pipes be insulated with polyvinyl chloride?

- Indeed, it is possible to insulate stainless steel pipes using polyvinyl chloride (PVC). PVC proves to be a popular choice for pipe insulation owing to its exceptional thermal properties and its ability to withstand moisture, chemicals, and corrosion. As a cost-effective solution, it effectively insulates the pipes, preventing the loss or gain of heat, and shields them from extreme temperatures, thereby reducing energy consumption. PVC insulation comes in various forms, including pre-formed tubes or sheets, making installation on stainless steel pipes a hassle-free process. However, it is crucial to ensure that the PVC insulation is compatible with stainless steel and adheres to the necessary industry standards to avoid any potential complications or deterioration of the pipes.

- Q: Can stainless steel pipes be recycled?

- Yes, stainless steel pipes can be recycled. Stainless steel is a highly recyclable material, and the recycling process can be done multiple times without compromising its quality or performance.

- Q: Stainless steel why rust?

- Stainless steel surface adhesion of organic juice (such as vegetables, soup, sputum), oxygen in the water under the circumstances, a long time, organic acid, organic acid on the surface of metal corrosion.

- Q: How do you prevent blockages in stainless steel pipes?

- To prevent blockages in stainless steel pipes, there are several measures you can take: 1. Regular cleaning: Clean the pipes on a regular basis to remove any accumulated debris or residue. This can be done using various cleaning methods such as mechanical cleaning tools or chemical cleaning solutions that are safe for stainless steel. 2. Proper disposal of waste: Ensure that you dispose of waste materials properly, avoiding dumping substances that can cause blockages, such as grease, oil, food scraps, or other solids. Use appropriate waste disposal systems or filters to trap these substances before they enter the pipes. 3. Avoid corrosive substances: Stainless steel pipes are resilient to corrosion, but exposure to certain highly corrosive substances can cause damage and blockages. Avoid using or disposing of chemicals or substances that are known to corrode stainless steel pipes. 4. Regular inspections: Conduct regular inspections of the pipes to identify any signs of blockages or potential issues. This can help in detecting problems early on and taking necessary preventive measures. 5. Proper installation: Ensure that the pipes are installed correctly, with proper alignment, support, and connections. This will help prevent the formation of blockages due to misaligned or poorly connected pipes. 6. Use strainers or filters: Install strainers or filters at the entry points of the pipes to catch any large particles or debris that can potentially block the pipes. Regularly clean or replace these strainers to maintain their effectiveness. 7. Avoid high-temperature buildup: Excessive heat can cause substances to solidify or congeal, leading to blockages. Avoid allowing substances to cool and solidify in the pipes by maintaining a suitable temperature and preventing sudden temperature changes. 8. Regular maintenance: Implement a regular maintenance schedule to keep the pipes in optimal condition. This can include activities such as flushing the pipes with hot water or using specialized cleaning solutions to remove any buildup or residue. By following these preventive measures, you can significantly reduce the chances of blockages in stainless steel pipes, ensuring their long-term functionality and minimizing the need for costly repairs or replacements.

- Q: What is the yield strength of stainless steel pipes?

- The yield strength of stainless steel pipes varies depending on the specific grade and composition of the stainless steel. However, stainless steel pipes generally have yield strengths ranging from 30,000 to 100,000 pounds per square inch (psi). It is important to note that the yield strength represents the point at which the material begins to deform permanently under applied stress. Therefore, it is crucial to choose the appropriate grade and thickness of stainless steel pipe based on the intended application and the specific mechanical properties required.

Send your message to us

201 Bright Annealing Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords