201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

Product Description

Specifications:

Grade: 200series; 300series; 400series

Thickness: 0.3mm-100mm

Width: 1000-1500mm

Length: 1000-6000mm

Main properties:

Basic corrosion resistance

Resistance against intergranular corrosion

Heat resistant alloy (medium temperature)

High ductility

Detailed Parameters:

Product Name | 201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats |

| Item Type | 201 Stainless steel |

| Grade | 201, 202, 301, 302, 304, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc |

| Standard | ASTM, AISI, DIN, EN, GB, JIS, ISO |

| Thickness | 0.3mm-100mm |

| Width | 1000-1500mm |

| Length | 1000-6000mm |

| Surface | 2B,NO.1,NO.4,HL,BA,8K |

| Edge | Slit/ /Mill Edge |

| Hardness | Full hardness to DDQ |

| Application | Utensils, kitchenware, food package,industry, construction,decoration etc. |

| Package | Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customer's requirements. |

| Payment term | T/T 30% deposit before production,70% balance before shipment. |

| Delivery Time | 2-5 days for sample order,within 10 days for formal order. |

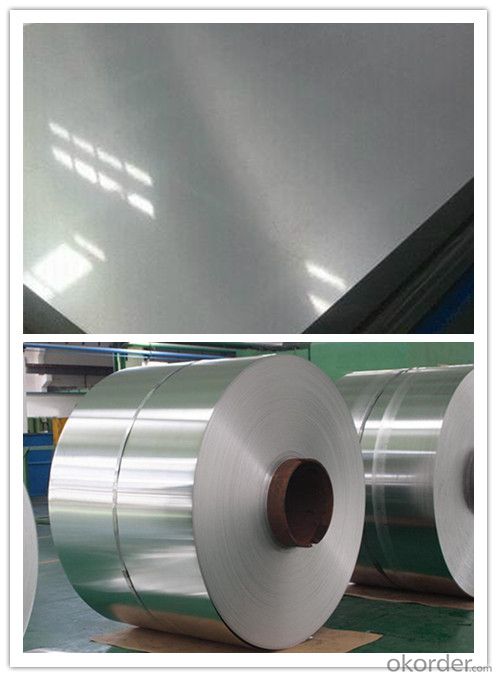

Product Display:

Chemical Composition:

| Grade | C(Max) | Mn (Max) | Si (Max) | P (Max) | S (Max) | Cr | Ni | Mo | Cu/others |

| 201 | 0.15

| 5.5-7.5 | 1 | 0.06 | 0.03 | 16.0-18.0 | 0.8-1.0 | ||

| 202 | 0.15 | 7.5- 10.0 | 1 | 0.06 | 0.03 | 17.0-19.0 | 4.0-6.0 | 1.4-1.5 | |

| 304 | 0.07 | 2 | 0.75 | 0.045 | 0.03 | 17.5-19.5 | 8.0-10.5 | - | |

| 304L | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 17.5-19.5 | 8.0-12.0 | - | |

| 309S | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | - | |

| 310S | 0.08 | 2 | 1.5 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | ||

| 316 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00- 3.00 | |

| 316L | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00- 3.00 | |

| 321 | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | Ti:5(C+N)min | |

| 410 | 0.08-0.15 | 1 | 1 | 0.045 | 0.03 | 11.5-13.5 | 0.75 | 0.70max | |

| 430 | 0.05 | 0.5- 1.0 | 0.6 | 0.045 | 0.03 | 11.5-14.0 | 3.5-5.5 | 0.50- 1.00 |

Surface Treatment:

| Surface | Image Display | Features |

| 2B |  | The surface brightness and flatness of 2B is better than 2D. Then through a specialsurface treatment to improve its mechanical properties, it could nearly satisfy comprehensive uses. |

| No.1 |  | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 |  | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL |  | Polished with abrasive belt of grit #150 #320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA |  | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |  | The product have excellent brightness and prefer reflexivity can be the mirror. |

Packaging & Shipping

1.Package: Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customer's requirements.

2.Shipping: If we have stocks, the delivery time is less than 5 weekdays,If the quantity is more than 500Tons,the delivery time is abou 30 days after confirming the order.Sample or bulk goods we would choose ship by air or by sea after talking with you.

Company Information

Certificate:

FAQ:

1.Q:Are you manufacture or trading company?

A:We are manufacture in Wuxi,Jiangsu Province,China(mainland).

2.Q:Who are your suppliers?

A:We have been working directly with TISCO,LISCO,ZPSS,BAOSTEEL for years.

3.Q:What are the advantages of your products?

A:We specialized in 200,300,400 series cold rolled stainless steel plates.Service for OEM/ODM,any others such as stainless steel strips and strips in coil also supplied on your request.

4.Q:How can I get samples?

A:Our samples are free,but we hope u can pay for the freight fee.2 ways for your choice.

1)U can provide us with an express account no. and contact information for shipping if u have.

2)If u do not have the express account,deposit the freight fee in advance.We will arrange the samples for you as soon as we get the deposit.

5.Q:How much for sending the samples?

A:The freight fee depends on the weight,package size,and the destination to load goods.We would choose the best way to forward.

- Q: What are the common uses of stainless steel sheets in the food industry?

- Due to their numerous beneficial properties, stainless steel sheets find wide application in the food industry. Food processing equipment is a common use for these sheets in this industry. Machines like mixing tanks, conveyors, and food processing tables are fabricated using these sheets. The preference for stainless steel sheets in this regard is due to their resistance to corrosion, ease of cleaning, and non-reactivity with food substances, which ensures the safety and hygiene of the food. Another prevalent use of stainless steel sheets in the food industry is for food storage and transportation. Containers, tanks, and barrels used for storing and transporting food products are often manufactured using stainless steel sheets. The corrosion resistance of stainless steel guarantees the protection of the food from contamination and spoilage during storage and transportation. Kitchen equipment in the food industry also heavily relies on stainless steel sheets. Countertops, sinks, and cabinets are frequently made from these sheets because of their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where maintaining hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment, such as ovens, grills, and refrigerators. These sheets play a crucial role in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In conclusion, stainless steel sheets are widely used in the food industry for various purposes, including food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: Are stainless steel sheets suitable for food storage containers?

- Yes, stainless steel sheets are suitable for food storage containers. Stainless steel is a popular choice for food storage containers due to its many beneficial properties. Firstly, stainless steel is non-reactive, meaning it does not interact with or leach any harmful chemicals into the food, ensuring that the taste and quality of the food is preserved. Additionally, stainless steel is resistant to corrosion, rust, and staining, making it a durable and long-lasting material for food storage containers. It is also easy to clean and maintain, as it does not absorb odors or flavors from previous food items. Furthermore, stainless steel is a hygienic material, as it does not harbor bacteria or other pathogens, ensuring that your food remains safe and healthy. Overall, stainless steel sheets are an excellent choice for food storage containers due to their suitability for contact with food, durability, and hygienic properties.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of both size and shape. They can be cut, bent, or shaped according to specific requirements, allowing for a wide range of customization options.

- Q: Are stainless steel sheets suitable for medical equipment or devices?

- Yes, stainless steel sheets are commonly used in the manufacturing of medical equipment or devices due to their excellent corrosion resistance, durability, ease of cleaning, and ability to withstand sterilization processes.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- Stainless steel sheets can be finished with various edge treatments to achieve different appearances and functionalities. These finishes serve to enhance the sheet's aesthetics, protect against sharp edges and potential corrosion. 1. Mill Finish: The standard edge finish for stainless steel sheets is the raw, untreated edge produced during manufacturing. While it may have a slightly rough or uneven appearance, it is functional and commonly used in industrial applications. 2. Deburred Edges: To eliminate any sharp or jagged edges, the stainless steel sheet can undergo deburring. This involves grinding or sanding down the edges to create a smoother and safer finish. Deburred edges are commonly chosen in safety-sensitive applications like food processing or medical equipment. 3. Rounded Edges: Rounded edges are achieved by utilizing a rounding tool to smooth out the sharp corners of the stainless steel sheet. This finish not only enhances the sheet's aesthetics but also reduces the risk of injury from sharp edges. Rounded edges are often favored for architectural or decorative purposes. 4. Beveled Edges: By cutting or grinding the edge of the stainless steel sheet at a specific angle, typically 45 degrees, beveled edges are created. This chamfered edge adds a sleek and modern appearance to the sheet. Beveled edges are commonly used in applications where aesthetics and design are important, such as furniture or interior design. 5. Polished Edges: Polished edges involve buffing or polishing the edge of the stainless steel sheet to achieve a smooth and mirror-like finish. This edge treatment adds a touch of elegance and sophistication, making it suitable for high-end architectural or decorative applications. To sum up, stainless steel sheets can be finished with mill finish, deburred edges, rounded edges, beveled edges, or polished edges. Each finish offers its own unique benefits and is chosen based on the specific requirements of the application.

- Q: Can stainless steel sheets be used for soundproofing?

- Stainless steel sheets alone are not typically used for soundproofing purposes. While stainless steel is known for its durability and corrosion resistance, it does not possess significant soundproofing properties. However, stainless steel sheets can be incorporated into soundproofing systems as part of a composite structure or in conjunction with other soundproofing materials to enhance their overall effectiveness.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are highly suitable for oil and gas equipment. Stainless steel has excellent corrosion resistance, high strength, and durability, making it an ideal choice for harsh environments and corrosive substances encountered in the oil and gas industry. Additionally, stainless steel's heat resistance and low maintenance requirements further contribute to its effectiveness in this field.

- Q: Can stainless steel sheets be used for architectural canopies?

- Yes, stainless steel sheets can be used for architectural canopies. Stainless steel is a durable and corrosion-resistant material that can withstand outdoor elements, making it suitable for use in canopies. It offers a sleek and modern appearance and can be customized to fit various design requirements.

- Q: Are stainless steel sheets suitable for food packaging equipment?

- Yes, stainless steel sheets are highly suitable for food packaging equipment. Stainless steel is a popular choice in the food industry due to its numerous advantageous properties. First and foremost, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, smell, or appearance. This makes it safe for direct contact with food products. Additionally, stainless steel is resistant to corrosion, rust, and staining, which ensures the durability and longevity of the equipment. It is also easy to clean and sanitize, making it ideal for maintaining high levels of hygiene required in food packaging processes. The smooth surface of stainless steel sheets minimizes the risk of bacterial growth and simplifies the cleaning process. Furthermore, stainless steel has excellent strength and heat resistance properties, allowing it to withstand high temperatures without deforming or compromising its structural integrity. This is particularly important in food packaging equipment where heat sealing or thermal processing is involved. In conclusion, stainless steel sheets are highly suitable for food packaging equipment due to their non-reactive nature, corrosion resistance, ease of cleaning, and high strength. These qualities make stainless steel a reliable and hygienic choice for ensuring the safety and quality of food products during packaging processes.

Send your message to us

201 304 316 310s Stainless Steel Sheets pipes coils Strips Bars Flats

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords