2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

Description

FRP sheets are made of fiberglass and polyester resin and continuously molded by machine.

They are characterized by high-light transmittance, light-weight, high-strength, corrosion resistance, impact resistance, anti-ultraviolet, anti-

static, heat preservation and insulation, accurate section dimensions and controllable cutting length. They can be used with various profiling panels and galvanized sheets.

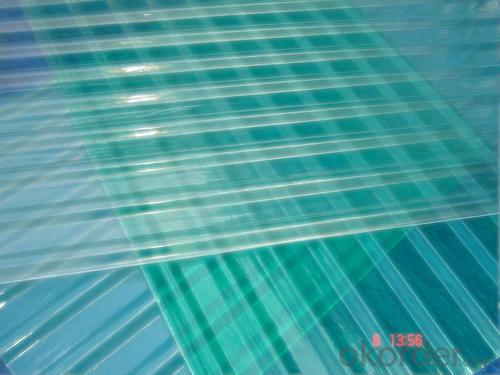

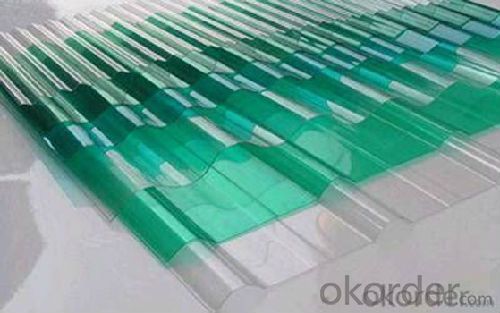

Photos

Product Traits

Good tenacity. No cracking phenomenon when driving nails in roof installation.

Having close combing with color steel plate. Cross-section thickness is uniform. The shape of FRP is consistent with steel plate.

Transmittance loss rate is low. No yellowing phenomenon after long term service.

Thermal expansion coefficient is close to that of steel plate. No cracking and water leakage in nail driving place because of expand with heat and contract with cold.

Light through FRP assumes scattering shape and gentle.

Bright and clean appearance. No distinct air bubble and cracking on FRP.

Anti-ultraviolet and anti-chemistry corrosion.

Anti-aging and anti-pulverization.

Long service life.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

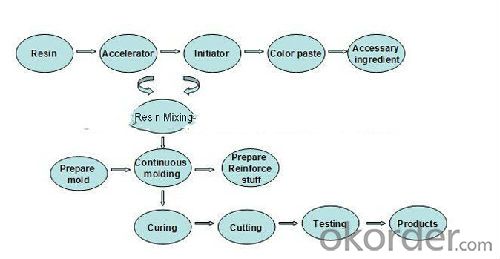

Production Process

Specification

Physical properties:

| Tensile strength | 80-100Mpa |

| Flexural strength | 0-110 Mpa |

| Density | 1.4-1.6g/cm³ |

| Pasteur | ≥40 |

| Heat conductivity factor | 0.67-0.96kv/m.h.°C |

| Temperature range | -40°C—+60°C |

| Water absorption | 24 hours ≤0.32% |

| Wind loading rating | below 8 levels |

| Curing degree | ≥82% |

Product classification:

Plate type | thickness(mm) | width(mm) | |

Flat plate | 0.7-4.0 | ≤1400 | |

Sine wave | 0.7-4.0 | ≤1200 | |

Trapezoidal wave | 0.7-4.0 | Mating with pressure plate | |

Fire resistance | Ordinary type | ||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Are FRP roofing panels resistant to damage from chemicals or pollutants?

- Yes, FRP roofing panels are highly resistant to damage from chemicals or pollutants. Their composite structure and protective coatings make them impervious to corrosion caused by various chemicals, acids, and pollutants commonly found in industrial environments. This resistance ensures the longevity and durability of FRP roofing panels, making them an excellent choice for areas with chemical exposure or high pollution levels.

- Q: Are FRP roofing panels resistant to bird nesting or infestations?

- Generally, FRP roofing panels exhibit resistance to bird nesting and infestations. The sleek surface of these panels poses challenges for birds in their search for suitable nesting spots. Furthermore, the material is not easily penetrable, preventing birds from forming holes or gaining access to the roof's interior. Nevertheless, it is worth mentioning that although FRP panels are resistant to bird infestations, they are not entirely impervious. Birds that are persistent or determined may still endeavor to construct nests on or around the panels. However, overall, FRP roofing panels prove effective in deterring bird nesting and infestations.

- Q: Are FRP roofing panels suitable for historical buildings or landmarks?

- FRP roofing panels, also known as fiberglass reinforced plastic, can be suitable for historical buildings or landmarks depending on various factors. Firstly, it is important to consider the specific requirements and characteristics of the building or landmark in question. Historical buildings are often protected by preservation laws or regulations that dictate the type of materials that can be used for restoration or repair. These regulations may prioritize maintaining the original architectural integrity and historical value of the structure. In such cases, using FRP roofing panels may not be suitable as they may not be aesthetically compatible with the original design. However, if the historical building or landmark does not have strict preservation requirements or if it has undergone significant alterations over time, FRP roofing panels can offer several advantages. FRP panels are lightweight, durable, and have a long lifespan. They can withstand harsh weather conditions, resist corrosion, and provide excellent insulation properties. Additionally, FRP panels can be manufactured to mimic the appearance of traditional roofing materials such as slate, clay, or wood, allowing for a more seamless integration with the existing architectural style. Furthermore, FRP roofing panels are relatively easy to install, reducing the overall time and cost of restoration or repair projects. They require minimal maintenance and can be resistant to common issues like rot, insect infestation, and decay, which are often associated with traditional roofing materials. Ultimately, the suitability of FRP roofing panels for historical buildings or landmarks depends on a careful evaluation of the specific needs and requirements of the structure, as well as compliance with preservation regulations. Consulting with preservation experts, architects, and engineers experienced in historical restoration can provide valuable guidance in determining the most appropriate roofing solution for each unique case.

- Q: Can FRP roofing panels be used for airport terminals or hangars?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for airport terminals or hangars. FRP panels are known for their durability, strength, and weather resistance, making them suitable for various applications, including airports. They provide excellent protection against harsh weather conditions such as rain, snow, and high winds. Additionally, FRP panels are lightweight, which makes installation easier and reduces the overall load on the structure. They also offer good thermal insulation properties, helping to maintain a comfortable temperature inside the terminal or hangar. Overall, using FRP roofing panels in airport terminals or hangars can provide a cost-effective and long-lasting solution.

- Q: Can FRP roofing panels be used for sports facilities?

- Yes, FRP roofing panels can be used for sports facilities. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their durability, strength, and resistance to weathering, making them suitable for use in various applications, including sports facilities. They offer excellent protection against UV rays, impact, and corrosion, ensuring a long lifespan and low maintenance requirements. Additionally, FRP panels are lightweight, easy to install, and can be customized to meet specific design requirements, making them a versatile choice for sports facility roofing.

- Q: Can FRP roofing panels be used for stadiums?

- Yes, FRP roofing panels can be used for stadiums. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to weather conditions, making them a suitable choice for stadiums. Additionally, FRP panels offer excellent light transmission properties, allowing natural light to illuminate the stadium while maintaining a comfortable indoor environment.

- Q: Can FRP roofing panels be painted or coated with a protective finish?

- FRP roofing panels can indeed be painted or given a protective finish. The smooth surface of these panels makes it easy to apply paint or coatings. However, it is essential to choose the right type of paint or coating that is compatible with FRP material. It is generally recommended to use acrylic or latex-based paints for FRP panels as they adhere well and offer good durability. Before applying any paint or coating, it is crucial to properly clean and prepare the surface by removing dirt, dust, or grease. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure optimal results and maintain the structural integrity of the FRP roofing panels.

- Q: Can FRP roofing panels be installed without professional assistance?

- Although FRP roofing panels can be installed without professional assistance, it is highly recommended to possess a certain level of knowledge, experience, and proper tools to achieve a successful installation. While FRP panels are generally lightweight and easy to handle, specific steps and precautions must be followed to guarantee a proper and secure installation. To begin with, it is imperative to thoroughly understand the manufacturer's instructions. These instructions typically provide details regarding the necessary tools, materials, and procedures for installing FRP roofing panels. Carefully adhering to these instructions is crucial in order to avoid any potential damage or safety hazards. Prior to installing FRP roofing panels, it is essential to adequately prepare the roof surface. This may involve cleaning the surface, eliminating any debris or loose materials, and ensuring a smooth and even surface to ensure proper adhesion. Throughout the installation process, it is crucial to employ suitable tools and techniques. This may include using a drill with appropriate drill bits for creating holes, utilizing screws or adhesive recommended by the manufacturer, and ensuring proper alignment and spacing of the panels. By following the recommended installation methods, a sturdy and watertight roof can be achieved. While it is possible to install FRP roofing panels without professional assistance, it is always advisable to consult with a professional or seek guidance from the manufacturer if any aspect of the installation process is unclear. They can provide valuable advice, address any inquiries, and ensure that the installation is executed correctly and safely.

- Q: Can FRP roofing panels be used for covered bike racks or bicycle shelters?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can definitely be used for covered bike racks or bicycle shelters. FRP panels are known for their durability, strength, and weather resistance, making them an ideal choice for outdoor structures like bike shelters. These panels are designed to withstand harsh weather conditions, such as rain, snow, and UV rays, ensuring the protection of the bikes from the elements. Additionally, FRP panels are lightweight and easy to install, making them a cost-effective solution for creating covered bike racks or shelters. With their ability to provide a sturdy and long-lasting shelter for bikes, FRP roofing panels are a popular choice among architects and builders for constructing bike shelters and racks.

- Q: Are FRP roofing panels suitable for architectural accents?

- FRP roofing panels are a perfect choice for architectural accents. Not only are they versatile and adaptable for various architectural applications, but they also offer exceptional durability. These panels are resistant to corrosion, UV rays, and harsh weather conditions, making them ideal for long-term use in outdoor settings. This means that they can be used as architectural accents without worrying about their deterioration or loss of aesthetic appeal over time. Moreover, FRP panels come in a wide array of colors, finishes, and patterns, allowing architects and designers to select panels that align with their desired aesthetic vision. Whether it's a modern, sleek appearance or a more traditional, textured look, FRP panels can be customized to suit a variety of architectural styles. Furthermore, FRP panels are lightweight and easy to install, making them a practical choice for architectural accents. They can be effortlessly shaped and manipulated to meet different design requirements, enabling creative and unique applications. To sum up, FRP roofing panels are unquestionably suitable for architectural accents. Their durability, versatility, and customizable options make them an excellent choice for enhancing the visual appeal and overall aesthetics of buildings.

Send your message to us

2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords