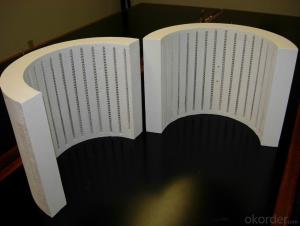

1260C ceramic fiber blanket 50mm 96kg/m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10-50mm |

| Width: | 610,1220mm | Length: | 3600,7200,14400mm | Chemical Composition: | Al2O3 |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1260,1260C | Fiber Diameter: | 3-4.5micron |

| Shrinkage (1800 ℉, 3h): | -3 | Thermal Conductivity: | 0.22 | Density (kg/m³ ): | 128 |

| Model Number: | 7200x610x25mm | Brand Name: | Place of Origin: | China (Mainland) | |

| color: | white |

Packaging & Delivery

| Packaging Detail: | bags |

| Delivery Detail: | within 10 days |

Product Description

Brief description

1.low thermal conductivity

2.excellent thermal stability

3.good tensile strength

4.excellent sound absorption

Main Technical Property Indexes

ceramic fiber blanke Type | Common

| Standard

| High Purity

| High Aluminium

| Zirconia

| |

Maximum temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | pure white | pure white | pure white | pure white | |

Density (kg/m3) | 96/ | 96/ | 96/ | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128kg/m3)128 kg/m3 | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3)128 kg/m3, | 0.09(400°C) | 0.09(400°C) 0.22(1000°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.176(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition

(%) | AL2O3 | ≥44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | <0.2 | <0.2 | <0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |

Size (mm) | Length: 14640/7200/3600 Width: 1220/610 Thicknes: 10-50 | |||||

Product Uses

Ceramic Fiber Blanket is Aerospace, steel, petrochemical heat insulation; Military equipment fire insulation; Industrial furnace, heating device wall lining, backing insulation; High temperature equipment insulation; Heat pipe heat insulation; Electrical components heat insulation fire; High temperature gaskets; Module, folded piece of raw materials

- Q: Slag ball content of ceramic fiber material?

- Effect of slag ball content on ceramic fiber materialSlag ball content ceramic fiber products is an important factor that affects the bulk density. Slag ball density in 2800 ~ 3200kg/m fand, excessive slag ball content fiber products, comprehensive energy-saving performance will reduce the ceramic fiber blanket, ceramic fiber module of ceramic fiber products, and damage the interests of users.

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Features: excellent chemical stability, excellent thermal stability, excellent tensile strength, low thermal conductivity, low thermal capacity, excellent sound absorption and noise reduction performance. Typical applications: aerospace, steel, petrochemical high temperature insulation; military road insulation; electrical components insulation; fire protection; high temperature gasket; modules, folding blocks of raw materials. Three. Ceramic fiber felt products: ceramic fiber vacuum forming felt is made of ceramic fiber cotton produced by resistance furnace injection molding. It is processed by vacuum forming process. It is a lightweight, flexible refractory fiber insulation material, made of a combination of high purity refractory oxides and organic binders. In addition to the excellent properties of bulk ceramic fiber cotton, the ceramic fiber vacuum forming felt has good strength and elasticity, and is a versatile product. Product characteristics: high strength, long service life; low heat capacity, low heat conductivity; non brittle material, toughness; size precision, good flatness; cutting easy installation, convenient construction; excellent anti erosion properties; continuous production, fiber distribution, stable performance; excellent acoustic noise performance.

- Q: Definition of ceramic fiber

- Ordinary ceramic fiber, also known as aluminum silicate fiber, because one of its main ingredients is alumina, and alumina is the main component of porcelain, so it is called ceramic fiber. The addition of zirconia or chromium oxide can further increase the utilization temperature of the ceramic fiber.Ceramic fiber products refers to the use of ceramic fiber as raw materials, through processing made of light weight, high temperature resistance, good thermal stability, thermal conductivity of industrial products, low heat resistance of small and mechanical vibration etc., specially used for all kinds of high temperature, high pressure, easy to wear in the environmentCeramic fiber product is a kind of excellent refractory material.

- Q: What is the process of producing ceramic fiber mats?

- Mifso-12 ceramic fiber pad is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.Can be customized by users to produce sizes.

- Q: What is ceramic fiber?

- 1, ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used.2, ceramic fiber products is a good refractory. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..3, light quality, good heat insulation performance, good thermal stability, good chemical stability, easy processing and convenient construction. It is neither wear-resistant nor collision resistant, can not resist the erosion of high-speed airflow, and can not resist the erosion of molten slag.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- Ceramic fiber, referred to as "ceramic fiber felt", is a kind of high temperature resistant refractory material (such as precious stones) by arc melting, compressed air sprayed with a fibrous material, also known as "ceramic fiber cotton.". Using ceramic fiber cotton, it can be made into all kinds of ceramic fiber products. The content of domestic ceramic fiber felt from AI2O3 is 62% and 45%, the former is 1150-2000 DEG C, and the latter is l000 DEG C.The ceramic fiber felt by the adhesive is divided into hard ceramic fiber felt (aluminum phosphate adhesive), ceramic fiber felt soft (adhesive latex, polymerization aluminum, water glass, methyl cellulose, latex 11 aluminum phosphate composite adhesive) and ceramic fiber wet felt (adhesive silica sol) three. According to the performance of the felt and the temperature of the furnace, the hot surface of the furnace wall can be made of hard felt.The size of the ceramic fiber product is 600 * 400 * 20 (10) mmThe basic properties of the felt are as follows:(L) the use of high temperature can reach l000 degrees centigrade.

- Q: The product characteristics of ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;

- Q: Can a series of ceramic fiber products be used in combination?

- Industrial furnace insulation backing: suitable for all types of industrial furnace (annular furnace, trolley furnace, pit furnace, furnace donburi etc.)Materials: ceramic fiber blanket, ceramic fiber module, ceramic fiber module.

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

Send your message to us

1260C ceramic fiber blanket 50mm 96kg/m3

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords