1260 Refractory Ceramic Fiber Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 6-50mm |

| Width: | 610mm,610mmx2 | Length: | 3660/4880/7320/9760/14640mm | Chemical Composition: | Al2O3:49% |

| Ultimate Strength (≥ MPa): | 0.08-0.12Mpa(128kg/m3) | Working Temperature: | 1100C | Fiber Diameter: | 3~5um |

| Shrinkage (1800 ℉, 3h): | -3 (hours) | Thermal Conductivity: | 0.09-0.16w/m.k(400-800C) | Model Number: | Ceramic Fiber Blanket |

| Brand Name: | Place of Origin: | (Mainland) | Color: | Pure white | |

| Certificate: | ISO9001:2000, MSDS, CE, REACH | Type: | Ceramic fiber blanket | Application of ceramic fiber blanket: | Refractory furnace lining,Furnace refractory,roof heat insulation seal |

| Operation Temp(C°): | 1100 | Width(mm) of the ceramic fiber blanket:: | 610, 1220 | Length(mm) of the ceramic fiber blanket:: | 14640, 9760, 7320, 4880, 3660 |

| thickness(mm) of ceramic fiber blanket:: | 6,13, 19, 25, 38, 50 | Chemical Composition (%): | Al2O3(45-46%) Al2O3+SiO2(≥98%) | Product Name: | Refractory Ceramic Fiber Blanket |

Packaging & Delivery

| Packaging Detail: | PE Bag,Carton box 525rolls/1x40HQ for ceramic fiber blanket products |

| Delivery Detail: | Within 15 days for ceramic fiber blanket |

| Ceramic fiber blanket Information | ||||||||||

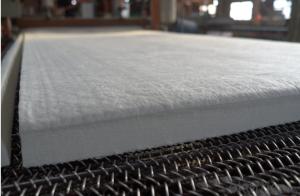

CCEWOOL ® Ceramic Fiber Blanket is a new type of fire-resistant insulation materials in white and tidy size, with integrated fire resistance, heat separation and thermal insulation functions, containing no any binding agent and maintains good tensile strength, toughness, and the fibrous structure when used in a neutral, oxidized atmosphere. CCEWOOL ® Ceramic Fiber Blanket can restore to original thermal and physical properties after drying, without any impact by oil corrosion. All CCEWOOL ® Ceramic Fiber Blankets are made though spun fiber production, and the corresponding fiber bulk has the same excellent chemical stability, high room-temperature strength and strength after burnt, which is widely used in various sectors of refractory, insulation, thermal insulation field. | ||||||||||

| Product Brief Introduction | ||||||||||

| Item:Ceramic Fiber blanketSTANDARDS OF TYPEBlanket:Density: 96kg/m³,128kg/m³,160kg/m³Thickness:6mm,13mm, 19mm, 25mm, 38mm, 50mmWidth: 610mm,1220mm21840x610x6mm, 14640x610x12.5mm, 7320x610x25mm, 4800x610x38mm, 3600x610x50mm1/4''x24''x860'', 1/2''x24''x600'', 1''x24''x300'', 1-1/2''x190, 2''x24''x140''Classification Temperature1050°C, 1260°C, 1400°C, 1450°CApplications:Soaking pit sealsExpansion joint sealsAnnealing cover sealsFire protection systemsHigh temperature gasketingGlass furnace crown insulationInvestment casting mould wrappings Incineration equipment and stack linings Kiln and furnace insulationInsulation for steam and gas turbinesRemovable insulationHigh temperature pipe and casting mold insulation.Repair, insulation and linings for furnaces, kilns, ovens, generators, reformers, boilers,Duct and turbine insulation- Forging furnaces linings- High-temperature seals and gasketFurnace door seals -Glass furnace crown insulation -Heat processing equipmentsCar bottom furnace lining insulation -Fire protective insulation or liningsAdvantagesResistance to high temperature Low thermal conductivity Resistance to thermal shockExcellent corrosion resistanceLow shot content Low heat storage High tensile strength Good sound absorption Double needled blanket -Low density -Low thermal conductivity -Shorter heat up and cool down timeResilience and resistance to thermal shock -Flexible and easy to cut and installContain no organic binder -Asbestos freePacking:In plastic bags and then in cartonsDelivery TimeWithin 15 days after received the deposit.CertificateISO, CE, REACH, MSDS can be providedThe third party inspectionBV, TUV, SGS

| ||||||||||

| Technical Data of ceramic fiber blanket | ||||||||||

| Classification(°C)Types1050 Ordinary Ceramic Fiber Blanket1260 Standard Ceramic Fiber Blanket1260 High-purityCeramic Fiber Blanket1400 High AluminiaCeramic Fiber Blanket1450 ZirconiaCeramic Fiber BlanketOperation Temp(°C)950°C(1742°F)1050°C(1922°F)1100°C(2012°F)1200°C(2192°F )1350°C(2462°F)Density(kg/m3)64-160Permanent Change on Heating(%)950°Cx24h≤-31050°Cx24h≤-31100°Cx24h≤-31200°Cx24h≤-31350°Cx24h≤-3Theoretic Heat Conductive Co-efficientW/(m·k)(128kg/m3)0.15(600°C)0.22(800°C)0.12(600°C)0.20(800°C)0.12(600°C)0.20(800°C)0.1(600°C)0.20(800°C)0.16(800°C)0.20(1000°C)Tensile Strength(Thickness 25mm)(Mpa)(25mm)≥0.04≥0.05≥0.05≥0.04≥0.06ChemicalCompositionAl2O3(%)4445-4647-4952-5539-40Al2O3+SiO2(%)≥96≥98≥99≥99-ZrO2(%)----15-17Al2O3+SiO2+ZrO2(%)----≥99Fe2O3(%)≤1.0≤0.8≤0.2≤0.2≤0.2Na2O+K2O(%)≤0.4≤0.3≤0.2≤0.2≤0.2CaO+MgO≤0.3≤0.2≤0.2≤0.2≤0.2 | ||||||||||

| Why choose our products? | ||||||||||

ceramic fiber blanket is made of ceramic long fiber that is produced by the melting of very pure raw materials in double surfaceneeding process without binders and with good stability in a large range of temperature. The process of double surface needing increase interweaving and tensile strength. | ||||||||||

- Q: Slag ball content of ceramic fiber material?

- 2800 ~ 3200kg/m the data of fand, right?Chasing the answerThis value is 2800 ~ 3200kg/m fand slag ball density, not ceramic fiber density

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Product Description: with stable performance, long fiber and tensile strength, less slag ball, high thermal stability, white color and so on. The classification temperature is 1050-1600 degrees centigrade. It is the preferred material for the production of fiber textiles. It is also an ideal material for sealing, filling and heat insulation in high temperature environment. Features: low thermal conductivity, low thermal capacity, excellent chemical stability, corrosion resistance, excellent sound absorption property, excellent thermal stability. Typical applications: raw materials for industrial ceramic fiber wet products; raw materials for ceramic fiber unshaped products; high temperature kilns, heating devices, wall linings, gap filling materials, etc.. Two, ceramic fiber blanket Product Description: white color, regular size, set fire, heat insulation, insulation in one. Free from any binding agent. In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade.

- Q: Definition of ceramic fiber

- The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..So far, Chinese domestic ceramic fiber manufacturers now have a total of more than 200 large and small, but the temperature is 1425 DEG C (zirconium containing fiber) production process and the following ceramic fibers, were divided into left and blowing two carpet carpet.

- Q: Brief introduction of ceramic fiber cloth

- Application range of ceramic fiber cloth:All kinds of kilns, high temperature pipes and containers insulation;Furnace door, valve, flange sealing, fire door and fireproof rolling curtain material, high temperature door, sensitive curtain;Insulation of engine and instrument, fireproof cable coating material, high temperature fireproof material;Material for heat insulation covering, high temperature expansion joint packing, flue lining;High temperature resistant labor protection products, fire retardant clothing, high temperature filtration, sound absorption and other application areas instead of asbestos.

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: What is the difference between the national standards for ceramic fiber products and ordinary aluminium silicate?

- Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of ceramic fiber products (aluminium silicate fiber products) is 22 - 33 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of ceramic fiber products (aluminum silicate fiber products) is more important. The range of Al2O3SiO2 fiber contraction in various products of 1260 C line is 35 - 88%. The amount of shrinkage is also directly related to thermal stability. Ceramic fiber products (aluminum silicate fiber products) as ceramic fiber products (aluminum silicate fiber products) with low thermal conductivity, low density, light weight, light steel frame are used in the design and construction of kilns supporting structure, so that the development of ceramic kiln kiln into the "lightweight" era. The fiber has small heat storage and is suitable for quick heating and cooling firing.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Inorganic refractory: CeramicHeavy industries (of fire furnaces)There are also organic polymers: halogen and halogen free construction"Ceramic fiber materials are generally used in heat insulation places, and can be used in all high temperature industries.

- Q: What is the use of ceramic fiber paper?

- Mifso-14 ceramic fiber paper gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced. Can be customized by users to produce sizes.

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- Soluble ceramic fiber is a new product and biodegradable. Beijing Fei Pufu

Send your message to us

1260 Refractory Ceramic Fiber Blanket

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords