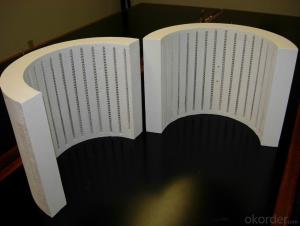

Heater Tubes with Ceramic Fiber Used in Furnaces

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

We use the imported High purified raw material to produce the tube heater, and the heater will be installed by different ways as customer required.

Ceramic Fiber Insulated Heater is available with heating element embedded in vacuum forming or installed on machined ceramic fiber blocks, in form of flat panel, half tube, tube or any custom made shapes.

Features:

Flexible and fast installation

Fast heating-up, cost effectively

Applications:

Various electric heating furnaces

Smallest laboratory furnace, largest production furnace

Pipe heating

Advantage:

◆Precise size

◆Short heating time

◆Easy installation

◆Low dust

◆Energy saving

◆Long service life

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

◆Low light

Data sheet

FURNACE INNER SIZE(D×W×H) | Voltage(V) | Power(W) | Service Temp(℃) |

φ25×152 | 120 | 420 | 0~1200 |

φ36×334 | 220 | 1500 | 0~1200 |

φ36×512 | 220 | 2400 | 0~1200 |

φ50×200 | 110 | 1000 | 0~1200 |

φ60×400 | 220 | 2000 | 0~1200 |

φ70×520 | 110 | 800 | 0~1200 |

φ80×400 | 220 | 1500 | 0~1200 |

φ160×500 | 380 | 6000 | 0~1200 |

φ240×480 | 380 | 6000 | 0~1200 |

φ90×280 | 220 | 2000 | 0~1200 |

φ100×500 | 220 | 2400 | 0~1200 |

φ120×420 | 220 | 3000 | 0~1200 |

φ190×570 | 380 | 8000 | 0~1200 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of ceramic fiber heaters?

The ceramic fiber heaters will be used in various electric heating furnaces,

smallest laboratory furnace, largest production furnace, pipe heating etc

---------What type of ceramic fiber heaters we can produce?

1. Flat panel

2. Half tube

3. Round tube

4. Box shape

5. Customers required shapes

----------what advantages of ceramic fiber heaters?

1. Precise size

2. Short heating time

3. Easy installation

4. Low dust

5. Energy saving

6. Long service life

7. Low thermal conductivity

8. High tensile strength

- Q: Slag ball content of ceramic fiber material?

- Slag ball content of ceramic fiber material?The content of 0.25mm foreign size > slag ball control in less than 5%, while domestic due to fiber manufacturing technology limit, content of slag ball control in less than 15%[1], which is nearly 1/8 fiber products in slag ball content twice as high than abroad. Therefore, in determining the bulk density of ceramic fiber products, we should give full consideration to the amount of slag ball.

- Q: Definition of ceramic fiber

- The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..So far, Chinese domestic ceramic fiber manufacturers now have a total of more than 200 large and small, but the temperature is 1425 DEG C (zirconium containing fiber) production process and the following ceramic fibers, were divided into left and blowing two carpet carpet.

- Q: Brief introduction of ceramic fiber cloth

- General specifications of ceramic fiber cloth: 1.5mm--6mm, average width is 1m, which is divided into (nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth fumigation) properties of ceramic fiber cloth:High temperature resistance, low thermal conductivity, thermal shock resistance and low heat capacity;Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;It has good low temperature and high temperature strength;Non-toxic, harmless, no adverse effects on the environment;

- Q: What is the process of producing ceramic fiber mats?

- 3) good high temperature strength and heat insulation performance (refer to physical and chemical indexes).4) having a higher level of electrical insulation and high temperature electrical insulation than glass fibers.5) non-toxic, harmless and odorless.

- Q: What is ceramic fiber paper?

- The specification is various, the thickness of 0.5-10mm. products using four consecutive rinsing and slag removal process, the fiber distribution, high tensile strength good flexibility, no delamination, no slag, can be cut with a little organic matter.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: Refractory ceramics and other refractory materials manufacturing is a big industry?

- Also belong to the building materials industry, glass industry and other industries, are Rong Sheng refractories industry ah.

- Q: The characteristics of ceramic fiber paper

- There are a lot of ceramic fiber paper called, some people call the fire-resistant fiber paper, insulation paper, aluminum silicate fiber paper, ceramic fiber paper is made from high purity ceramic fiber production, used in the field of high temperature insulation, advanced production technology makes the fiber distribution is very uniform, density and volume of paper can be strictly controlled.There are three kinds of ceramic fiber paper: standard ceramic fiber paper, high alumina ceramic fiber paper and zirconium ceramic fiber paperCeramic fiber paper features: low heat capacity, ground heat conductivity, good electrical insulation performance, excellent mechanical processing performance, easy to cut, strong and tear resistance; high flexibility; low slag ball content

- Q: Can a series of ceramic fiber products be used in combination?

- Ceramic fiber products is referred to, including ceramic fiber, ceramic fiber blanket, ceramic fiber, ceramic fiber module, ceramic fiber paper, ceramic fiber folded block, ceramic fiber blanket, ceramic fiber, special-shaped pieces of Castable Ceramic fiber, ceramic fiber spray coating, ceramic fiber cloth, ceramic fiber, ceramic fiber rope dozens of products, ceramic fiber products are combined to use in the process of using.

- Q: How to choose the right ceramic fiber and aluminum silicate products?

- 3, according to the thickness of insulation to chooseThere are a lot of insulation thickness of furnace is fixed, the insulation thickness of conventional material is inappropriate, only according to the heat flow calculation formula to calculate the appropriate level of insulation material is the most scientific, the conventional case raised to two of the product can be registered.

Send your message to us

Heater Tubes with Ceramic Fiber Used in Furnaces

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords