Electric Heater with Ceramic Fiber Used in Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

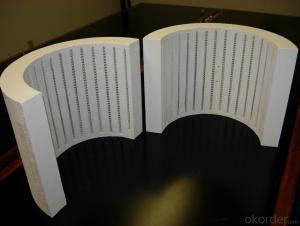

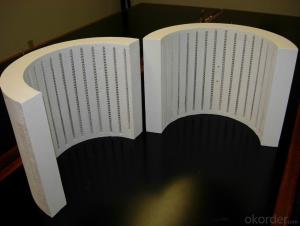

Ceramic fiber shaped products are produced by vacuum-filtrating forming process. Fibers of various shaped for various circumstances are available according to customer's requirements. The specifications and the temperature requirements all depends on the customer.

There are two ways can be choosed to install the furnace wire: Vertical and around.

Application:

This kind of ceramic fiber heating module is mainly use in the pre-heating furnace, melting furnace, high temperature furnace, vacuum furnace, porcelain burning furnace.

Advantage:

◆Precise size

◆Short heating time

◆Easy installation

◆Low dust

◆Energy saving

◆Long service life

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

◆Low light

Data sheet

FURNACE INNER SIZE(D×W×H) | Voltage(V) | Power(W) | Service Temp(℃) |

φ25×152 | 120 | 420 | 0~1200 |

φ36×334 | 220 | 1500 | 0~1200 |

φ36×512 | 220 | 2400 | 0~1200 |

φ50×200 | 110 | 1000 | 0~1200 |

φ60×400 | 220 | 2000 | 0~1200 |

φ70×520 | 110 | 800 | 0~1200 |

φ80×400 | 220 | 1500 | 0~1200 |

φ160×500 | 380 | 6000 | 0~1200 |

φ240×480 | 380 | 6000 | 0~1200 |

φ90×280 | 220 | 2000 | 0~1200 |

φ100×500 | 220 | 2400 | 0~1200 |

φ120×420 | 220 | 3000 | 0~1200 |

φ190×570 | 380 | 8000 | 0~1200 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

--------What is the use of ceramic fiber heaters?

The ceramic fiber heaters will be used in various electric heating furnaces,

smallest laboratory furnace, largest production furnace, pipe heating etc

---------What type of ceramic fiber heaters we can produce?

1. Flat panel

2. Half tube

3. Round tube

4. Box shape

5. Customers required shapes

----------what advantages of ceramic fiber heaters?

1. Precise size

2. Short heating time

3. Easy installation

4. Low dust

5. Energy saving

6. Long service life

7. Low thermal conductivity

8. High tensile strength

- Q: Which expert to help, urgent?! Thank you, 20Is the type of refractory material, shaped like cotton mattress like, but not really cotton, is some ore and some artificial material is made into the refractory with high temperature of one thousand degrees, will not change the kind of.

- Aluminium silicate refractory fiber cotton custom HS Code: 68061000.9068129900 refractory fiber cotton (containing asbestos)84748090 aluminium silicate refractory fiber cotton and its product line equipment

- Q: Who can help me introduce the principle of vacuum forming of ceramic fiber board? Thank you very much.

- Product Description: with stable performance, long fiber and tensile strength, less slag ball, high thermal stability, white color and so on. The classification temperature is 1050-1600 degrees centigrade. It is the preferred material for the production of fiber textiles. It is also an ideal material for sealing, filling and heat insulation in high temperature environment. Features: low thermal conductivity, low thermal capacity, excellent chemical stability, corrosion resistance, excellent sound absorption property, excellent thermal stability. Typical applications: raw materials for industrial ceramic fiber wet products; raw materials for ceramic fiber unshaped products; high temperature kilns, heating devices, wall linings, gap filling materials, etc.. Two, ceramic fiber blanket Product Description: white color, regular size, set fire, heat insulation, insulation in one. Free from any binding agent. In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade.

- Q: Definition of ceramic fiber

- 1. Definition of ceramic fiber:Ceramic fiber is a fibrous lightweight refractory.2, ceramic fiber expansion:Ceramic fiber, also known as aluminum silicate fiber, is the main component of refractory fiber!HLGX ceramic fiber is the refractory material with the lowest thermal conductivity and the best heat insulation and energy saving effect except the nanometer insulation material. The utility model has the advantages of light weight, high temperature resistance, good heat insulation effect, convenient construction, etc., and is a lining material of high quality industrial furnaces. Ji'nan dragon hot Ceramic Co., Ltd. has HLGX ceramic fiber module, HLGX ceramic fiber blanket and other ceramic fiber products widely used in kiln insulation project, high temperature equipment, pipe insulation.3. The origin of ceramic fiber appellation:First of all we want to know the origin and development of ceramic fiber, ceramic fiber first appeared in 1941, the United States Babu Hancock. Cox Newell company with natural kaolin by the arc furnace melt blown fiber. In 1950s, the ceramic fiber was put into industrialized production. In 60s, a variety of products were developed and used as lining for industrial furnaces.Thus, we know that ceramic fiber originated in the United States, and its name "Ceramic Fiber", literally translated literally "Ceramic - ceramic, Fiber - fiber, combination is" ceramic fiber".

- Q: Brief introduction of ceramic fiber cloth

- General specifications of ceramic fiber cloth: 1.5mm--6mm, average width is 1m, which is divided into (nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth fumigation) properties of ceramic fiber cloth:High temperature resistance, low thermal conductivity, thermal shock resistance and low heat capacity;Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;It has good low temperature and high temperature strength;Non-toxic, harmless, no adverse effects on the environment;

- Q: What is ceramic fiber paper?

- Ji'nan Huolong ceramic fiber paper is made from high purity ultrafine ceramic fiber cotton by dispersing agent evenly dispersed, high temperature binder and a dilution ratio of the mixed, heated by microwave drying was prepared.

- Q: What ceramic fiber profiled products are needed in steel mills? What's the name?

- Ceramic fiber and nano heat insulation board are used for heat insulation, and in the steel plant are generally used for ladle, tundish insulation, and now can also be made of nano insulation products special-shaped products.

- Q: What kind of material is ceramic fiber? What are the basic performance?

- Ceramic fiber is a fibrous lightweight refractory material, has the advantages of light weight, high temperature resistance, good thermal stability, low thermal conductivity, specific heat and resistance to mechanical vibration, and thus in machinery, metallurgy, petroleum, ceramics, glass, electronics and other industries have been widely used in recent years because of. The global energy prices rising, energy saving has become a China national strategy background, than other traditional insulation bricks and refractory pouring material such as 10-30% ceramic fiber has been applied more and more widely in the domestic Chinese, the development prospects are very promising.Ceramic fiber products refers to the use of ceramic fiber as raw materials, through processing made of light weight, high temperature resistance, good thermal stability, thermal conductivity of industrial products, low heat resistance of small and mechanical vibration etc., specially used for all kinds of high temperature, high pressure, easy to wear in the environmentScope of application:Ceramic fiber product is a kind of excellent refractory material. The utility model has the advantages of light weight, high temperature resistance, small heat capacity, good insulation and heat insulation performance, good high-temperature heat insulation performance, no toxicity, etc..Technical parameter:The temperature is -100 DEG C, -+1200 DEG CPressure 0-20MPaChemical tolerance pH value 4-14

- Q: The product characteristics of ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life;With corrosion resistance, aluminum, zinc and other non-ferrous metal erosion capacity;

- Q: ceramic fiber

- Advantages of ceramic fiberRefractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining. Ji'nan Sheng Yang

- Q: At present, the field of ceramic fiber, what is the latest development of technology or products?

- The latest technology -- Research and development of ceramic fiber composite. HLGX ceramic fiber composite insulation board is a new super insulation material produced by semi dry process, which is the first in the world. The difference between it and imported aerogel composite insulation board is reinforced fiber changes (replaced by glass fiber ceramic fiber), change of substrate and adiabatic main material ratio, and the addition of other nano additives. The promotion point of innovation -- resistance to temperature liftingHighest 800 C to 1000 C, long-term working temperature shrinkage rate decreased from 3% down to 2%, there is a big boost for high temperature applications, only the production process is complicated, the cost is still high.

Send your message to us

Electric Heater with Ceramic Fiber Used in Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords