AAA Grade WBP Glue Film Faced Plywood for Construction Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Model Number: 1220*2440,1250*2500,915*1830

· Usage: Outdoor

· Grade: First-Class

· Main Material: poplar, birch, hardwood

· Formaldehyde Emission Standards: E2

· Plywood Type: 7-21ply

· Size: 1220*2440mm,1250*2500mm

· Thickness: 9-25mm

· Core: poplar, combi, hardwood

· Film: black, brown, red

· Glue: MR,WBP

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by seabundled by steel strip |

Delivery Detail: | within 15 days after receiving prepay or against origin L/C |

Product Specification:

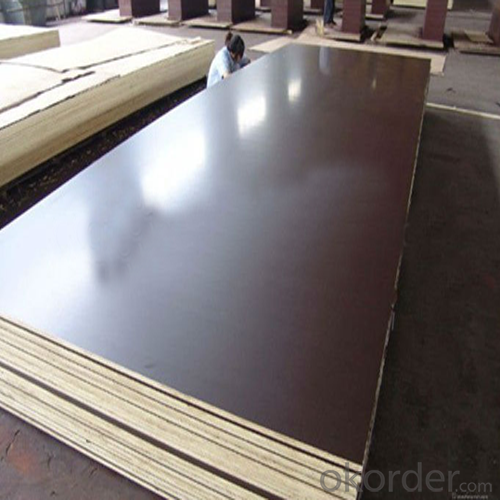

AAA grade WBP glue brown and black film faced plywood for concrete

Name | WBP glue Film faced plywood |

Film color | Black, brown, red (can print logo) |

Core Materials | poplar, combi, hardwood, birch |

Glue | MR, Melamine, WBP |

Size | 1220*2440*9-25mm 915*1830*9-25mm 1250*2500*9-25mm |

Moisture | 6-14% |

Modulus of rupture | more than 30Mpa |

Modulus of Elasticity | more than 6000Mpa |

Reuse times | more than 10 times |

Usage | Construction |

Packing | inside wrapped by 0.2mm plastic bag, outside by carton box and bundled by steel strip or as per your request |

Market | Asia, Middle East, Africa, Europe, Latin America, Ect. |

Certificate | ISO 9001,BV |

Payment terms | L/C, TT |

Delivery time | within 15days after receiving prepay or against origin L/C |

Product Feature:

1) High bending strength

2) little linear expansion con efficient

3) Strong nail holding

4) Moisture proof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If put in boilding water for 24 hours, it is still glue sticking and nondeformed.

10) If used abide by the illustration strictly, it can be reused more than 30 times

11) Solve the problems of leaking and rough surface during construction process, particular suitable for watering concrete.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: What kind of support is needed

- Is the outer cover sandwich plate? With purlins and wall beams connected, purlins and wall girders connected with the steel structure, the specific you according to a steel structure of the building plans to see to know. Sandwich panels and purlins are self-tapping screws.

- Q: Whether the rock wool sandwich panel is environmentally friendly

- How to say this, the board itself is environmentally friendly, the production process is not environmentally friendly ~

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- OKorder Wang Teng Choi Steel Structure Co., Ltd. specializing in the production of sandwich panels foam sandwich panels Yanmian sandwich panels polyurethane sandwich panels glass wool cotton sandwich panels paper honeycomb sandwich panels aluminum honeycomb sandwich panels phenolic sandwich panels hand sandwich panels stainless steel Sandwich panel sandwich panel offer sandwich panel specifications sandwich board type sandwich panel manufacturer sandwich panel density sandwich panel thickness sandwich panel wholesale sandwich panel sales sandwich panel suppliers - OKorder Wang Teng color steel structure limited the company

- Q: Is the sandwich panel toxic? Now we live with a sandwich board to do the house, listen to friends that sandwich board toxic, is it true?

- Sandwich panels are environmentally friendly materials, how many are a bit, no big problem, you can rest assured that use. But I would like to remind is in the color of the steel house, pay attention to the improper use of the kitchen to prevent fire. For the quality of sandwich panels, the world color steel is good to understand the next.

- Q: 100 thick composite sandwich board how much money a square meter upper plate 0.6 lower 0.4

- Sandwich panels are also different from Yan Yan or benzene board or glass wool

- Q: Suzhou Yanmian sandwich board which is good?

- It is recommended to consider Suzhou Fu new purification equipment Technology Co., Ltd., the company is specialized in the purification equipment R & D and production, purification engineering design, purification engineering construction, purification project maintenance clean room vacuum cleaner, laminar flow hood FFU, clean shed and electrostatic products sales Comprehensive technical services of high-tech enterprises. It can provide professional air purification system engineering design for air electronics, biomedical, hospital operating room, fiber optic cable, food and beverage, precision instrument, semiconductor and new material application, air purification system engineering, air purification system engineering inspection and air Purification system engineering and technical services; according to the customer's actual requirements and the actual needs of the design, manufacture, installation of clean room systems and equipment. So you can consider buying and cooperating.

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: What is the polyurethane fireproof grade?

- 1) thermal conductivity of low polyurethane sandwich panel composite board thermal conductivity is small, good insulation properties, is the best insulation materials. 2) panel appearance, easy to install 3) Polyurethane sandwich panel fire resistance is good 4) Polyurethane sandwich board non-toxic and tasteless 5) use a wide temperature range 6) waterproof, moisture Polyurethane sandwich panel shape beautiful, the overall effect is good, it sets load, insulation, fire, waterproof in one, and no secondary decoration, quick and easy installation, short construction period, comprehensive benefits, and has a good price advantage, Widely used, highly potential energy efficient building envelope materials, but also the Ministry of Construction to promote and promote a new energy-saving sheet.

- Q: 50mm thick insulation color steel sandwich board with J * B42-333 * 1000 What does this mean?

- 42 for the high corrugated slope, 333 for the distance between the center of the slope, 1000 for the practical area, this sandwich panel is not common

Send your message to us

AAA Grade WBP Glue Film Faced Plywood for Construction Usage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords