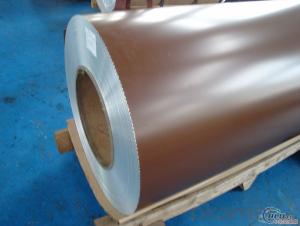

027 Aluminum Coil - Alloy 3003 Aluminum Roll for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy 3003 Aluminium Roll for Roofing/Ceiling/Gutter/Decoration

Specification

Aluminium sheet | |||||

Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

A1050,A1060, A1070, A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

3A21, A3003, A3105, A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

A5052, A5005, A5083, A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

A6061, A6082, A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

Packing: Export wooden pallets. The bundle weight not exceed 2MT. Loading: by 1x20GP, 1X20GP can load about 18MT | |||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

MOQ | 5 tons | ||||

Payment term | T/T,L/C | ||||

Delivery Time | 15-60 days after 30% T/T payment or receiving L/C copy | ||||

Kind attention: Specifications can be customized as the customer’s requirements. | |||||

Packing

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: What are the typical standards and specifications for packaging aluminum coils?

- <p>The standard specification for aluminum coil packaging varies depending on the industry and region, but generally includes the following: The coil is typically wrapped in a protective film to prevent damage and corrosion. It is often strapped with steel or plastic bands to secure the coil during transportation. The packaging may also include wooden pallets or crates for stability. The dimensions and weight of the packaging are tailored to the coil's size and thickness. Compliance with international standards such as ASTM, ISO, or specific industry standards is crucial. It's important to note that exact specifications can differ based on customer requirements and the end-use application of the aluminum coil.</p>

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. Aluminum is a popular choice for condenser coils due to its excellent heat transfer properties, durability, and resistance to corrosion. Additionally, aluminum coils are lightweight, making them easier to install and transport.

- Q: How are aluminum coils used in solar panels?

- Aluminum coils play a crucial role in the manufacturing and functioning of solar panels. Solar panels convert sunlight into electricity, and aluminum coils are used as a key component in the construction of the panel itself. Firstly, aluminum coils are utilized as the base material for the solar panel's frame. The frame is responsible for providing structural support and stability to the panel, ensuring it can withstand various environmental conditions such as wind, rain, and snow. Aluminum is preferred for this purpose due to its lightweight nature, corrosion resistance, and durability. In addition to the frame, aluminum coils are also employed in the creation of the solar panel's backsheet. The backsheet is a protective layer that covers the rear surface of the panel, shielding it from moisture, heat, and other external factors. Aluminum coils are often laminated with other materials, such as polymers or glass, to form a strong and impermeable backsheet. Moreover, aluminum is an excellent conductor of electricity. Solar panels consist of individual solar cells, which generate direct current (DC) electricity when exposed to sunlight. Aluminum coils are utilized to create the electrical connections between these cells, allowing the flow of electricity within the panel. Furthermore, aluminum coils are used in the manufacturing of the panel's wiring and connectors. These components are responsible for collecting the generated electricity and transmitting it to an inverter, which converts it into alternating current (AC) electricity suitable for use in homes and businesses. Aluminum's conductivity and low resistance make it an ideal material for efficiently transferring electrical energy. Overall, aluminum coils are essential in the construction and functionality of solar panels. They provide structural support, form protective layers, enable electrical connections, and facilitate the efficient transmission of electricity. With the increasing demand for renewable energy, the use of aluminum coils in solar panels continues to play a vital role in harnessing the power of the sun to generate clean and sustainable electricity.

- Q: This question asks for guidelines on safely transporting aluminum coils, which are large and heavy metal rolls used in various industries.

- <p>To transport aluminum coils safely, follow these steps: Use specialized vehicles with proper securing mechanisms to handle the weight and prevent rolling. Ensure the coils are balanced and secured with straps or chains to avoid shifting during transit. Maintain a steady speed to minimize vibrations that could cause damage. Avoid sudden stops or sharp turns. Keep the load covered to protect from moisture and dirt. Adhere to all legal weight and dimension limits for your route. Regularly inspect the vehicle and load for any signs of damage or instability. Always follow local transportation regulations and safety guidelines.</p>

- Q: Are aluminum coils suitable for insulation applications?

- No, aluminum coils are not suitable for insulation applications.

- Q: If the aluminum coil is 220 kg, 0.3 thick and 500 wide, how much is the coil diameter?

- With the outer diameter and inner diameter, you can know the volume. With the density and volume, we can calculate the weight. And with weight, we can know the length.

- Q: What are the common surface finishes for aluminum coils in the aerospace industry?

- Some common surface finishes for aluminum coils in the aerospace industry include anodizing, chromate conversion coating, and primer coating. Anodizing is a process that creates a protective oxide layer on the surface of the aluminum, providing enhanced corrosion resistance and durability. Chromate conversion coating, also known as chemical film coating, forms a thin layer on the aluminum surface that provides corrosion resistance and improves adhesion for subsequent coatings. Primer coating is typically applied on top of anodizing or chromate conversion coating to provide additional protection and enhance the adhesion of subsequent paint layers. These surface finishes are important in the aerospace industry as they help to protect the aluminum coils from corrosion and ensure their longevity in harsh environments.

- Q: I need to make aluminum powder that is fine! I don't have a mill to use or something like that. If I fill literally the whole coffee blender, will that get it fine? I want to make an ok amount of it. I tried to use sand paper which makes it as fine as I want it but takes a while of sanding.

- Dissolve it with an acid--vinegar's your best bet there unless you've got a way to get a hold of a stronger acid that'll do this quicker. Once all the aluminum's dissolved, put in some magnesium like you can get from one of those fire starting tools that's just a brick of magnesium with a spark strip on it. The magnesium will ionize and the aluminum will precipitate out of the solution. Add the magnesium in as small of individual quantities as you can, too, to keep the size of individual precipitate particles down. Also, I recommend neutralizing the acid before adding the magnesium in case there's any acidity left--baking soda will work fine and doesn't stink like ammonia. If the solution's too acidic when you add the magnesium, the magnesium will go for the acid instead of the aluminum.

- Q: Are there any limitations to using aluminum coils?

- Using aluminum coils comes with several limitations. Firstly, their cost is higher compared to other materials like copper, which can be a constraint for those with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means they are less efficient at transferring heat, resulting in decreased performance in some applications. In addition, aluminum is more prone to corrosion and oxidation than other materials. This limitation is particularly relevant in highly corrosive environments, like coastal areas or industrial settings. Moreover, aluminum coils are generally unsuitable for high-pressure applications. They are more likely to experience leaks or failures under high pressure, which restricts their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are less malleable than copper coils, making them more challenging to handle during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, although aluminum coils have advantages like being lightweight and environmentally friendly, their limitations must be carefully considered based on the specific application and requirements.

- Q: what is the most likely charge for aluminum cation?the answer is +3, but why? how can i figure this out with different ones?

- Aluminum has 3 valence electrons and it will try to get rid of these to end up with the outer valence shell being full. Electrons have a negative charge though, so getting rid of one brings the actual charge up, so it ends up +3.

Send your message to us

027 Aluminum Coil - Alloy 3003 Aluminum Roll for Roofing/Ceiling/Gutter/Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords