1/4 Sheets Aluminum - High Quality Aluminium Coil PVDF Coating Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

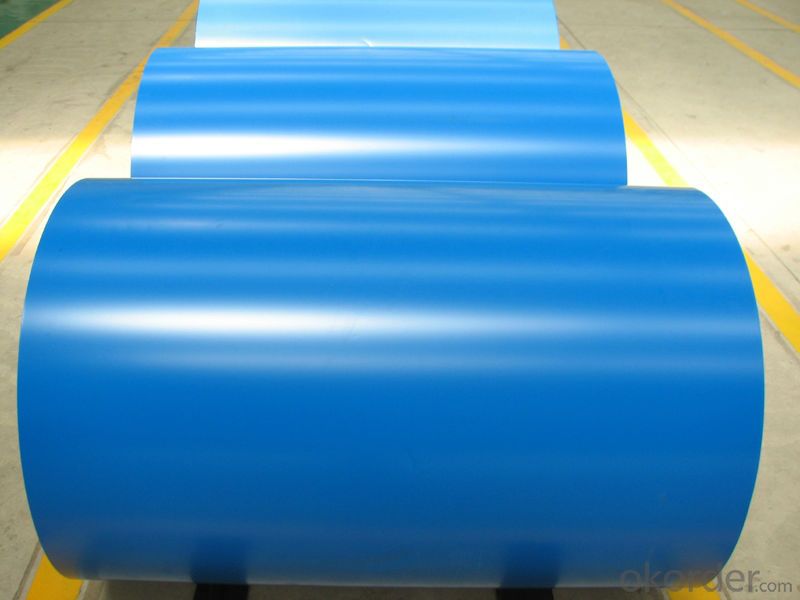

Structure of Aluminium Coil PVDF Coating Painted Hight Quality Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

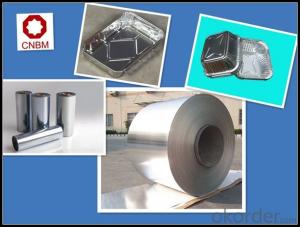

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil PVDF Coating Painted Hight Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

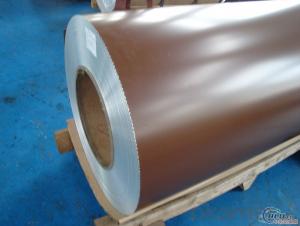

Images of the Aluminium Coil PVDF Coating Painted Hight Quality:

Aluminium Coil PVDF Coating Painted Hight Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Coil PVDF Coating Painted Hight Quality:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum sheet be used for aerospace structural components?

- Yes, aluminum sheet can be used for aerospace structural components. Aluminum is a commonly used material in the aerospace industry due to its desirable properties such as high strength-to-weight ratio, corrosion resistance, and good formability. The use of aluminum sheet for structural components allows for the construction of lightweight aircraft, which is crucial for fuel efficiency and performance. Additionally, aluminum is readily available and cost-effective, making it a popular choice for aerospace applications. However, it is important to note that the specific grade and thickness of the aluminum sheet used will depend on the particular requirements and specifications of the aerospace structural component.

- Q: Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry due to their lightweight, high strength, and corrosion resistance properties. They are used in the construction of aircraft structures, such as fuselages, wings, and interior components, to ensure optimal performance and fuel efficiency.

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: which has more volume? a kg of gold or a kg of aluminum? please explain in physics terms

- Think of it this way: Which metal is lighter? How do you know this? Because a given volume of gold weighs more than a given volume of aluminum. So which one has more volume? A kg of aluminum.

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: My mother has this idea that when her boyfriend puts coals from the wood stove in aluminum containers to warm the house that inhaling the fumes can cause Alzheimer's disease later in life. I am just curious about the truth of it.

- yes, aluminum is seriously bad, I knew a man that worked with aluminum and he was only 26 years old and his brain went completely blank. Research it.

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: How do aluminum sheets perform in terms of thermal expansion and contraction?

- Aluminum sheets possess a relatively high coefficient of thermal expansion, causing them to expand and contract more than most other materials when subjected to heat or cold. The coefficient of thermal expansion for aluminum is approximately 23 x 10^-6 per degree Celsius. Consequently, for each degree Celsius rise in temperature, aluminum expands by 23 millionths of its original size. This thermal expansion and contraction characteristic of aluminum renders it suitable for various applications where temperature fluctuations are anticipated. For example, in the construction industry, aluminum sheets are commonly utilized for roofing and cladding purposes. These sheets can endure the thermal stresses resulting from changing temperatures without experiencing significant warping or distortion. Additionally, this particular attribute of aluminum makes it an ideal choice for the production of items such as cookware and heat sinks. Aluminum cookware heats up rapidly and evenly due to its high thermal conductivity, while expanding uniformly to prevent warping or deformation when exposed to heat. Similarly, aluminum heat sinks effectively dissipate heat generated by electronic components as they can accommodate thermal expansion without compromising their structural integrity. However, it is important to acknowledge that although aluminum sheets possess favorable thermal expansion and contraction properties, extreme temperature changes can still result in some dimensional alterations. Therefore, careful consideration of the expected temperature variations is essential when designing and utilizing aluminum sheets to ensure their optimal performance and durability.

- Q: Are aluminum sheets suitable for heat exchangers?

- Aluminum sheets, indeed, are well-suited for heat exchangers due to their numerous advantageous qualities. Firstly, aluminum, being a highly conductive metal, facilitates efficient heat transfer, effectively enhancing the performance of the heat exchanger. Furthermore, its lightweight composition simplifies the handling and installation process within heat exchanger systems. Moreover, aluminum exhibits remarkable resistance against corrosion, guaranteeing the heat exchanger's endurance and sturdiness. Additionally, the malleability of aluminum sheets enables effortless shaping and sizing, thus enabling customization for various heat exchanger designs. In summary, aluminum sheets provide exceptional thermal conductivity, corrosion resistance, and versatility, rendering them a fitting choice for heat exchanger applications.

Send your message to us

1/4 Sheets Aluminum - High Quality Aluminium Coil PVDF Coating Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords