1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Alloy Wire Description:

Aluminum Alloy Wire is acid and alkali resistant, corrosion resistance, high strength, good toughness, and it does not fade at high temperatures (120 ℃). So products with aluminum-magnesium alloy micro wire would not deform easily, and there is a good shielding effect.

Featured by small density and high strength, the aluminum magnesium alloy tool is the lightest metal component material at present. Aluminum magnesium alloy wire can be used for core wire (as a substitution of copper wire) and shielding weaving wire which are widely applied to all kinds of communication cables, coaxial cables, being the supporting products of broad band transmission network and communication network.

2.Main Features of the Aluminum Alloy Wire

The wire is no oil stain on the wire surface

The wire surface is very smooth, and there is no burrs

The wire is very beautiful

The wire surface is bright

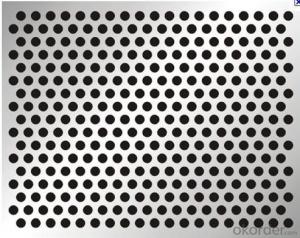

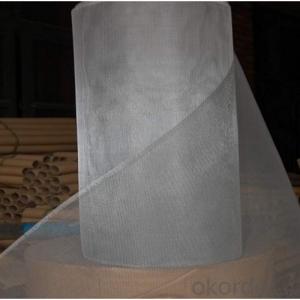

3.Aluminum Alloy Wire Images

4.Aluminum Alloy Wire Specification

Alloy | Uyimate Tensile Strength (PSI) | Electrical Resistance | Density (g/cc) | Melting Point |

1100 | 13000 | 18 | 2.71 | 645° |

1350 | 13000 | 17 | 2.70 | 648° |

1199 | 6800 | 15 | 2.70 | 660° |

2024 | 27000 | 20.25 | 2.78 | 638° |

3003 | 16000 | 20.25 | 2.73 | 654° |

4043 | 21000 | 25 | 2.69 | 632° |

5005 | 18000 | 19.95 | 2.70 | 654° |

5052 | 28000 | 10.2 | 2.68 | 649° |

5056 | 42000 | 36 | 2.64 | 605° |

6061 | 17000 | 22 | 2.70 | 617° |

5.FAQ

1) What is quality?

We are a state-owned company and ranked No267th of Fortune 500 in 2014. There is no need of worry about quality.

2) How is your delivery time:

In General, it will take 25days

3) How about your service?

We have a professional Inspection Team.

- Q: What type of cable should be used for direct buried lighting cables?

- Commonly used armored forms are: steel tape, aluminum tape armored, steel wire, aluminum wire armored, steel and steel wire composite armor, etc., according to the protective characteristics of cables, choose different forms of armor.

- Q: Welding problem: the problem of welding aluminum wire with lead

- This is not welded by lead. It is welded with a special solder, M51 tin wire. It is specially used for soldering M51- welding

- Q: What are the factors associated with the speed of the reaction between aluminum and acids?

- The reaction temperature is different and the reaction time is different, so the reaction speed is related to temperature;

- Q: Can solder aluminum wire with tin wire?

- No, aluminum is a very special material. The heat transfer is too fast, the surface is easy to oxidize, and the protective layer is formed. Special solder must be used.

- Q: Stainless steel soup bucket leaking how to do?

- You can find a better welder to repair it.

- Q: How to tell how thick the wire is?

- The so-called square, refers to not square meters, but square millimeters. The copper wire in the middle of the wire, the aluminum wire, is round, and these rounded section area is the square of these.

- Q: How do you make the faucet HOSE?

- Furthermore, adjust the pressure to take machine embossing mold elastic, put a head to the embossing (embossing hose is six cap and braided hose connection the stainless steel cap). Not too tight not too loose as copper core, embossing mold need to reset, just like the other end in embossing. The hose will be fine. It's only packed. Pointed hose (single hole, hot water hose) 40CM, 50CM, that's hard to say. It's entirely cut by the length of the pointed tooth. Pointed teeth have 28 heads, 32 heads, 38 heads, 42 heads and 100 heads. Others are the same as above

- Q: What is the color of the PC material after aluminizing?

- The specific color will be determined by the color of the PC film itself.

- Q: Is the resistance of metal wire plastic increased when it is plastically deformed?

- Steel wire has a wide range of uses. It can be used to make manganese phosphating coating, steel wire rope, galvanized steel strand and steel cord, etc..

- Q: What are the specific effects of a fuse in an appliance?

- If they are replaced by copper, iron, aluminum wire, their melting point is greater than or equal to the melting point of the wire, it will not be able to cut off the current. Burn a circuit or appliance, so copper, iron, aluminum wire cannot be used instead of a fuse

Send your message to us

1/0 1/0 1/0 Aluminum Wire for Window Screen Woven Mesh

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords