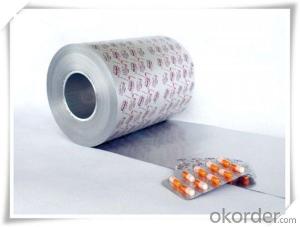

Aluminum Foil for Blister Packs

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.The reflectivity of bright aluminium foil is 88% while dull embossed foil is about 80%.

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: "Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium."

Davy settled on aluminum by the time he published his 1812 book Chemical Philosophy: "This substance appears to contain a peculiar metal, but as yet Aluminum has not been obtained in a perfectly free state, though alloys of it with other metalline substances have been procured sufficiently distinct to indicate the probable nature of alumina."[69] But the same year, an anonymous contributor to the Quarterly Review, a British political-literary journal, in a review of Davy's book, objected to aluminum and proposed the name aluminium, "for so we shall take the liberty of writing the word, in preference to aluminum, which has a less classical sound."

The -ium suffix conformed to the precedent set in other newly discovered elements of the time: potassium, sodium, magnesium, calcium, and strontium (all of which Davy isolated himself). Nevertheless, -um spellings for elements were not unknown at the time, as for example platinum, known to Europeans since the 16th century, molybdenum, discovered in 1778, and tantalum, discovered in 1802. The -um suffix is consistent with the universal spelling alumina for the oxide (as opposed to aluminia), as lanthana is the oxide of lanthanum, and magnesia, ceria, and thoria are the oxides of magnesium, cerium, and thorium respectively.

The aluminum spelling is used in the Webster's Dictionary of 1828. In his advertising handbill for his new electrolytic method of producing the metal in 1892, Charles Martin Hall used the -um spelling, despite his constant use of the -ium spelling in all the patents[58] he filed between 1886 and 1903. It has consequently been suggested[by whom?] that the spelling reflects an easier-to-pronounce word with one fewer syllable, or that the spelling on the flyer was a mistake.[citation needed] Hall's domination of production of the metal ensured that aluminum became the standard English spelling in North America.

- Q: I am able to bend a (thin) bar of aluminum with my hands but not a steel bar.

- eat healty lose weight today

- Q: Baking Powder has so much sodiumAlso I'm suspicious of the Aluminum in some brandsCan't you let the flour rise for an hour with yeast instead of using BP?

- Coffee Cake 3 to 3 1/2 cups all-purpose flour 1 cup sour cream 2 tablespoons granulated sugar 2 tablespoons butter or margarine, softened 1 teaspoon salt 1 package regular or quick active dry yeast 1/4 cup very warm water (120°F to 130°F) 1 egg 1/4 cup butter or margarine, melted 1/3 cup packed brown sugar 1/4 cup honey Filling 1/2 cup chopped nuts 1/3 cup butter or margarine, softened 1/4 cup honey 1In large bowl, mix 1 cup of the flour, the sour cream, granulated sugar, 2 tablespoons butter, the salt and yeastAdd warm waterBeat with electric mixer on low speed 1 minute, scraping bowl frequentlyBeat on medium speed 3 minutes, scraping bowl frequentlyBeat in eggStir in enough flour, 1 cup at a time, to make dough easy to handle 2Turn dough onto lightly floured surfaceKnead about 5 minutes or until smooth and elasticPlace in greased bowl and turn greased side upCover and let rise in warm place about 1 hour or until doubleDough is ready if indentation remains when touched 3In ungreased 13x9-inch pan, mix 1/4 cup butter, 1/3 cup brown sugar and 1/4 cup honey; spread evenly in panPunch down doughOn floured surface, flatten dough with hands or rolling pin into 24x9-inch rectangle 4In small bowl, mix all filling ingredients until well blendedSpread filling crosswise over half of rectangle to within 1/4 inch of edges of dough; fold crosswise in halfSeal edges; cut rectangle crosswise into 6 (2-inch) stripsTwist each strip loosely; place strips crosswise in panLet rise until double, about 1 hour5Heat oven to 375°FBake 20 to 25 minutes or until coffee cake is golden brownImmediately turn upside down onto heatproof serving plateLet stand 1 minute so honey mixture will drizzle over coffee cake -.

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper. Generally, aluminum has a tensile strength ranging from 70 to 700 MPa (megapascals).

- Q: some1 said to once.but.an electron IS part of the atom.so i dont see how this makes sense.so.yes or no or hard to explain.?

- True Research shows extra fiber in the diet can carry fats out of the intestines, and reduce cholesterol levels.

- Q: Conspiracy web sites and Internet radio shows say that the swine flu vaccine contains mercury, aluminium, formaldehyde, antifreeze, aspartamine, MSG, monkey kidney and lung cells and human and bovine fetal tissueWhy would a vaccine need artificial sweetener aspartamine? I am not going to inject any of those ingredients into my body.

- That is all rubbishThey don't have a clue, what do they know? If all of the conspiracy theorists are right then no one would get the vaccineMost people know there are theories about the evilness of the vaccine, yet most still get itWho and why really wants to inject people with the cocktail of substances you listed? And don't you think the side effects from those chemicals would be very apparent? Some people think it has a tracking chip so the government will know our every move People have answers for everything but the groups with mass hysteria and absolute paranoia don't normally provide the best answersJust because someone says something does not make it true.

- Q: I wrapped some auminum foil around the aluminum hose connecting my dryer to the wall, it was torn some.is this a fire hazard or am I ok!!! Thanks

- not going to cause fire but it will leak use duct tape to cover hole that is what it is made for originlally

- Q: Oxford cloth moistureproof aluminum foil moistureproof which good?

- Ordinary foam mats in June 11, 2010... 30 yuan for a single most with inflation but two can be together at 60... Leisure travel tent outdoor camping tent fabric: 180T waterproof breathable taffeta fabric material: PU2000 Oxford cloth... Two tents: Rental with moisture-proof pad, a deposit of 60 yuan, the rent is 15 yuan / times 2, double aluminum foil moistureproof mat 3, ordinary hollow cotton bag...

- Q: what is the relationship between the number of atoms in sodium's outer shell and aluminum's outer shell?1sodium has more electrons in the outer shell2aluminum has more electron in the outer shell3carbon and aluminum have the same number of electrons in their outer shells4This cannot be determined.

- LoveU, Aluminum has more electrons in its outer shell (3) than sodium (1)Hope that helped!

- Q: A method for recycling scrap aluminum converts it to alum [potassium aluminum sulfate dodecahydrate, KAl(SO4)212H2O].What is the maximum amount of alum (in metric tons) that can be prepared from 2.32 metric tons of scrap aluminum (1 metric ton 1000 kg)? Answer is 40.7 but I have no clue how to solve this problem.

- 1 mole of KAl(SO4)212H2O has 1 mole of Al so using molar masses: 2.32 metric tons Al (474.39 g/mol KAl(SO4)212H2O / ( 26.98 g/mol Al) 40.79 metric tons I get 40.8 metric tons differing only on how one rounds off whem adding up the molar masses (p.sthe (g/mol) / (g/mol) molar mass units cancel out , leaving you with units of metric tons)

Send your message to us

Aluminum Foil for Blister Packs

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords