0270a00983 Aluminum Coil - Aluminum Coated Strips for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coated Strips Used for Ring-Pull 5182 H48

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

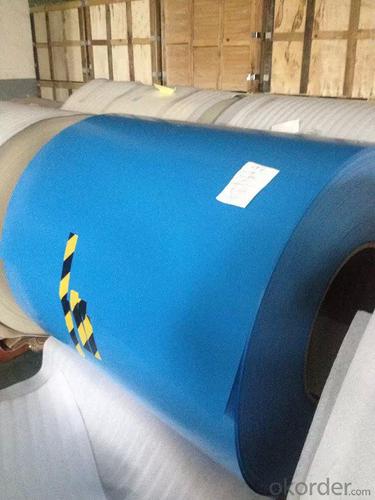

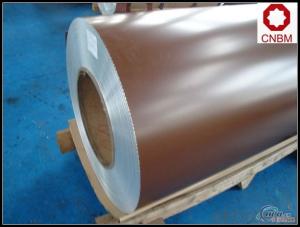

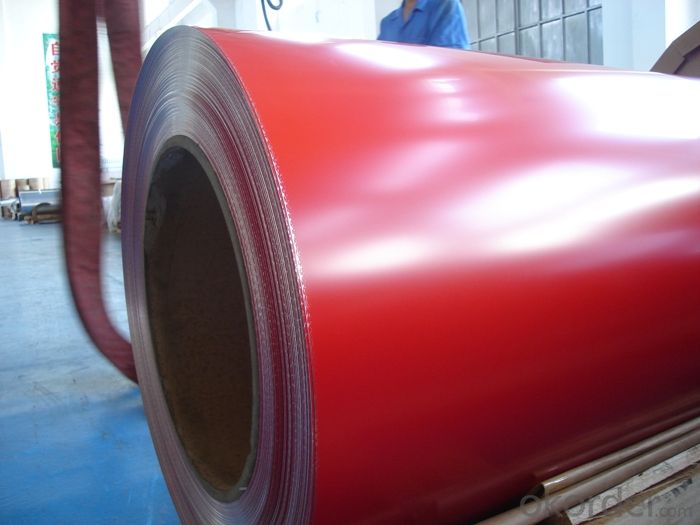

Our coated aluminum strips for tabs are colorful and glossy. We have different colors for tabs, such as blue, red, transparent, etc. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Aluminum Coated Strips Used for Ring-Pull 5182 H48

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Aluminum Coated Strips Used for Ring-Pull 5182 H48 Images

4. Specification of Aluminum Coated Strips Used for Ring-Pull 5182 H48

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How are aluminum coils used in the production of automotive radiators?

- Aluminum coils are used in the production of automotive radiators as they provide excellent heat transfer properties. These coils are typically made from aluminum alloy, which is lightweight, corrosion-resistant, and has high thermal conductivity. The coils are formed into a specific shape and then attached to the radiator's core. As coolant flows through the coils, heat from the engine is transferred to the aluminum, which efficiently dissipates it. This helps in cooling the engine and maintaining its optimal operating temperature. Overall, aluminum coils play a crucial role in enhancing the efficiency and performance of automotive radiators.

- Q: Are aluminum coils suitable for solar reflectors?

- Indeed, solar reflectors can indeed be made using aluminum coils. Aluminum, being highly reflective and durable, is extensively employed as a material for solar reflectors. Its reflective surface effectively redirects sunlight towards the intended destination, be it a solar panel or collector. Moreover, the lightweight and malleable nature of aluminum coils make them perfect for crafting curved or angled reflector surfaces. The reflective coating on these coils is also capable of enduring harsh weather conditions, ensuring long-lasting functionality. All in all, aluminum coils are an exceptional option for solar reflectors, given their reflectivity, durability, and adaptability.

- Q: I want to separate the copper and aluminum so I will get more at the scrap yard for my radiators any one know of an easy way to do this? Thanks

- Does your scrapyard not have a good price for aluminum/copper radiators? Mine does. I Don't think you can separate them short of melting off the aluminum. The copper goes right through it. It would be a lot of work to separate them. Much more work than stripping copper wire. Before I take a load of scrap, I call all of the yards and get the best price. Sometimes this varies as much as $.50/pound on copper and radiators and brass and clean aluminum. Work with your phone, it will make you money. Last I checked, #1 copper 3.10/pound #2: 2.90, Radiators $1.50, Brass $1.40, Insulated copper wire $1.10 to $.90 Aluminum $.85 to $.55 dependingScrap Metal(steel). $9.00/100 Lets recycle Car batteries are $6 ea.

- Q: May anyone tell me what's the product when hydrochloric acid reacts with aluminum?HCl + Al → ?

- Amonia Hydrochlorite

- Q: This question asks if aluminum coils are susceptible to rusting.

- <p>Aluminum coil does not rust in the traditional sense. Instead, it forms a thin, protective layer of aluminum oxide when exposed to air, which prevents further corrosion. This oxide layer is different from rust, which is iron oxide. While aluminum can tarnish or corrode under certain conditions, such as exposure to certain chemicals or in extreme environments, it does not rust like iron or steel. Proper storage and handling can help maintain the integrity of aluminum coils and prevent unwanted reactions.</p>

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils are widely acknowledged for being remarkably high. Aluminum, as a material, possesses a remarkable strength-to-weight ratio, which renders it suitable for diverse applications that necessitate both strength and lightweight characteristics. The specific tensile strength of aluminum coils can vary based on the alloy and temper employed. In general, aluminum coils exhibit a tensile strength ranging from 110-310 MPa (megapascals), or approximately 16,000-45,000 psi (pounds per square inch). These figures denote the maximum tensile stress that the aluminum coil can endure before it fractures or permanently distorts. It should be emphasized that the tensile strength can be further improved through heat treatment procedures like cold rolling or annealing. On the whole, aluminum coils are renowned for their impressive tensile strength properties, which contribute to their extensive utilization in industries such as aerospace, automotive, construction, and manufacturing.

- Q: What are the different hardness levels of aluminum coils?

- There are various hardness levels of aluminum coils, which are classified based on the alloy and tempering process used during their manufacturing. The most common hardness levels for aluminum coils are: 1. Soft (O temper): This is the most malleable and ductile state of aluminum coils. They are highly formable and suitable for applications that require extensive shaping or bending. 2. Quarter Hard (H12 temper): Aluminum coils in this hardness level have undergone a slight cold-working process, which increases their strength and stiffness. They are less malleable than soft coils but still retain good formability. 3. Half Hard (H14 temper): Coils in this hardness level have undergone a moderate cold-working process, resulting in further increased strength and stiffness. They are less formable than quarter-hard coils but are ideal for applications that require higher strength. 4. Three Quarter Hard (H16 temper): Aluminum coils in this hardness level have undergone a more intensive cold-working process, making them even stronger and less formable than half-hard coils. They are suitable for applications that require high strength and minimal deformation. 5. Full Hard (H18 temper): Coils in this hardness level have undergone the most extensive cold-working process, resulting in maximum strength and minimal formability. They are commonly used in applications that require high structural integrity and resistance to deformation. It is important to note that the specific hardness levels available for aluminum coils may vary depending on the alloy and manufacturer. Additionally, different industries and applications may have specific requirements for hardness levels, so it is crucial to choose the appropriate hardness level based on the intended use of the aluminum coils.

- Q: Can aluminum coils be utilized in the process of welding?

- <p>Yes, aluminum coils can be used for welding work. They are commonly used as filler material in processes like MIG (Metal Inert Gas) welding. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need for shielding from oxidation. The aluminum coils must be of good quality and compatible with the welding process to ensure a strong and durable weld. Proper selection of welding parameters, such as amperage and voltage, is crucial for successful aluminum welding.</p>

- Q: Can aluminum coils be used in food storage facilities?

- Aluminum coils are capable of being employed in food storage facilities. The food industry extensively employs aluminum due to its exceptional properties, including its lightweight nature, durability, resistance to corrosion, and effective heat conductivity. These attributes render aluminum coils suitable for a variety of applications within food storage facilities. Refrigeration systems, air conditioning units, and food storage cabinets are just a few examples of where aluminum coils can be utilized. Furthermore, aluminum is non-toxic and has no adverse reaction with food or its flavor, thus establishing it as a secure option for food storage. However, it is crucial to ensure that the aluminum coils used in food storage facilities undergo proper cleaning and maintenance to prevent any potential contamination.

- Q: I have completely disassembled my aluminum bass boat and it is being sandblasted.I am restoring the boat and will be giving it a new paint job.What do you recommend in the way of primer,paint or anything else I need to know.I just don,t want to mess it up by using the wrong thing.Best answer gets a fishing trip in the same boat we are talking about. If you can make it here I will put you on some fish.Catfish,bream,crappie,bass or even saltwater fish.

- Whatever okorder

Send your message to us

0270a00983 Aluminum Coil - Aluminum Coated Strips for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords