Aluminum Coated Strips used for Can tabs 5182H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coated Strips Used for Can Tabs 5182 H48

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

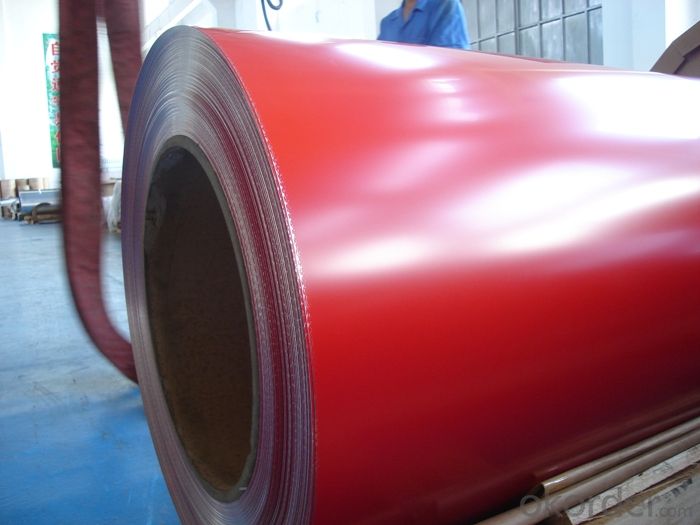

Our coated aluminum strips for tabs are colorful and glossy. We have different colors for tabs, such as blue, red, transparent, etc. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Aluminum Coated Strips Used for Can Tabs 5182 H48

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Aluminum Coated Strips Used for Can Tabs 5182 H48 Images

4. Specification of Aluminum Coated Strips Used for Can Tabs 5182 H48

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum strips.

- <p>Aluminum strips offer several advantages, including high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. They are lightweight, which makes them ideal for applications where weight is a concern, such as in the aerospace and automotive industries. Their resistance to corrosion means they can be used in environments where other metals might rust or degrade. Additionally, their thermal conductivity makes them useful in heat exchangers and other thermal management applications. However, aluminum strips also have disadvantages. They are less rigid than some other metals, which can be a drawback in applications requiring high stiffness. They also have a lower melting point compared to metals like steel, which can limit their use in high-temperature applications. Furthermore, aluminum is a good conductor of electricity, which might be undesirable in certain electrical applications where insulation is needed.</p>

- Q: Explain how aluminum strips can impact the fuel efficiency of a vehicle.

- <p>Aluminum strips, when used in the context of vehicle fuel efficiency, typically refer to the use of aluminum in vehicle construction to reduce weight. Aluminum is a lightweight material with high strength, which can significantly decrease the overall weight of a vehicle. By reducing the weight, the engine doesn't have to work as hard to move the vehicle, leading to less fuel consumption. Additionally, lighter vehicles can accelerate and decelerate more quickly, which can also contribute to improved fuel efficiency. However, it's important to note that the impact on fuel efficiency can vary based on the vehicle's design, driving conditions, and other factors.</p>

- Q: Classification of aluminium strips of aluminium strips

- There are specific uses: aluminum aluminum (aluminum foil transformer) transformer, high frequency welding hollow aluminum strip, aluminum strip used for aluminum fin radiator belt, cable aluminum strip, aluminum strip, aluminum strip punching with aluminum belt etc..

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: Explain the environmental effects of utilizing recycled aluminum.

- <p>The use of recycled aluminum has a significant positive impact on the environment. It reduces the need for mining bauxite, which is the primary source of aluminum, thereby decreasing deforestation and habitat destruction. Recycling aluminum also conserves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to reduced greenhouse gas emissions, contributing to the fight against climate change. Additionally, recycling aluminum reduces the amount of waste sent to landfills, lessening the environmental burden of waste disposal. Overall, the use of recycled aluminum promotes sustainability and helps protect natural resources.</p>

- Q: Is it possible to utilize aluminum strips in the construction of car covers or covers for other types of vehicles?

- <p>Aluminum strips can be used for car covers or covers for other vehicles, but their application is limited. Aluminum is lightweight and corrosion-resistant, which are desirable properties for vehicle covers. However, it lacks the flexibility and durability of materials like fabric or vinyl, making it less suitable for covering vehicles. Aluminum strips might be used as a reinforcement in the edges or corners of a cover, but they are not typically the primary material for the cover itself. It's important to consider the specific needs and conditions that the cover will be subjected to when choosing materials.</p>

- Q: What types of aluminum strips are more appropriate for commercial use?

- <p>Yes, there are specific types of aluminum strips that are more suitable for commercial applications. These include 1100 series aluminum strips, known for their high purity and excellent formability, making them ideal for general commercial purposes. 3003 series aluminum strips are also popular due to their enhanced corrosion resistance and formability, suitable for applications requiring moderate strength and good workability. Additionally, 5052 series aluminum strips offer good corrosion resistance and weldability, making them suitable for applications in the marine and transportation industries. The choice of aluminum strip depends on the specific requirements of the commercial application, such as strength, corrosion resistance, and formability.</p>

- Q: What specific cleaning techniques should be employed for maintaining an aluminum strip roof?

- <p>When cleaning an aluminum strip roof, it's important to use gentle cleaning methods to avoid damaging the metal. Use a soft brush or broom to remove debris and avoid using abrasive tools that could scratch the surface. For cleaning solutions, opt for mild detergents mixed with water, and avoid harsh chemicals that could corrode the aluminum. Always rinse thoroughly to remove any residue. Never use high-pressure water or steam cleaners, as they can cause dents or warp the aluminum. Regular maintenance, such as checking for and sealing any leaks, will also help prolong the life of your aluminum strip roof.</p>

Send your message to us

Aluminum Coated Strips used for Can tabs 5182H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords