0.05-4.0mm Thickness 125 Aluminum Sheets in Spfd Mo for Household

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

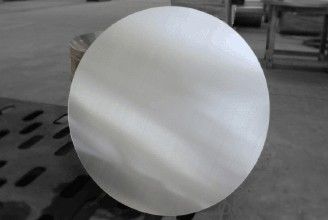

0.05-4.0mm Thickness Aluminum Circle For Household

Packaging & Delivery

| Packaging Details: | 25kg/carton-boxes(35*32*19CM) &Fumigation wooden-pallets (110*110*15cm) 20GP can loading 22 Ton,total 21 pallets,20 CBM. |

| Delivery Detail: | within 25 days |

Specifications

1).Excellent Surface Quality for lighting reflectors.

2).Excellent deep drawing and spinning quality.

3).Anodizing Quality

Aluminium circle/Aluminium discs/disks for cooking utensils Cookware

Aluminum disc Surface Finish: Bright & smooth surface, without flow lines, slightly oiled to avoid White rusting.Smooth,Brightly ,No Zone of Fracture ,No Scratched ,No oil Sludge

We enjoy a good reputation among our customers for our aluminum circle with high quality and competitive price, win high appreciation from our clients with the excellent workman-ship and professional ability. The quality matches with ISO 9001 quality management system.

It is equipped with 5 hot tandem rolling line, 4 cold mill production lines, 4 annealing surface machines and a complete finishing equipment.

Specification:

Alloy

Temper

Specification

Thickness

Diameter

1070,1050,3003,1100

O,H12,H14,H16

0.5-5.0mm

100-1200mm

Aluminum disc chemical Properties(WT.%)

Alloy

Si

Fe

Cu

Mn

Mg

Cr

Ni

Zn

Ca

V

Ti

Other

Min.A1

1050

0.25

0.4

0.05

0.05

0.05

-

-

0.05

-

0.05

0.03

0.03

99.5

1070

0.25

0.25

0.04

0.03

0.03

-

-

0.04

-

0.05

0.03

0.03

99.7

3003

0.6

0.7

0.05-0.2

1.0-1.5

-

-

-

0.1

-

-

-

0.15

96.95-96.75

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: What are the distinctions between standard aluminum windows and those that are custom-made?

- <p>Standard aluminum windows are mass-produced and come in set sizes and styles, offering affordability and quick installation. They may not fit perfectly into unique spaces and may lack customization options. Custom-made aluminum windows, on the other hand, are tailored to specific dimensions and design preferences, ensuring a perfect fit and enhanced aesthetics. They often come with more features and options, such as energy efficiency, security, and unique styling, but are typically more expensive and have a longer lead time for production and installation.</p>

- Q: Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a lightweight yet durable material that offers excellent protection against various environmental factors such as corrosion, moisture, and UV rays. It is commonly used in industries such as automotive, aerospace, and construction for manufacturing enclosures to shield sensitive components or equipment from potential damage.

- Q: When Aluminium nitrate is heated , i got yellow amorphous solid which did not not melt on further heating. What compound is that?

- Aluminium nitrate follows the rules for metal nitrate decomposition. Group I nitrate Na K etc --- nitrite + oxygen Other metal nitrate --- Metal Oxide + nitrogen dioxide + oxygen So your final product is aluminium oxide.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: how would you use aluminum to extract silver from film?just ideas please

- The silver in film is part of a silver salt (silver halides.) It is a very very small amount, probably less than 1 cent worth per roll. You would be a lot better off selling the film than trying to extract the silver from it. If you are hell bent on it, the first step is to expose the film to light. This will break the silver from the halides. Then you can go about trying to figure out how to get the silver apart from the film. I am sure it is possible, but it would involve a lot of work. I imagine you you would spend about $100 on ever $1 worth of silver you could extract.

- Q: I saw a guy on ebay take a washed out paint can fill it full of lighted charcoal bricks and a tin can in the middle. He was melting aluminum cans in there then pured it into a mold. Does this really work and does anyone have any good ideas on how else to do this?

- Aluminum alloys melt at around 1200 degrees, aluminum cans maybe somewhat lower, but I doubt a tin can would hold up long enough to melt much aluminum, and you would need to be very careful, any moisture in your mold will cause the aluminum to literally explode back into your face. I am not saying it couldn't be done, but you really would need lots of safety equipment before trying it.

- Q: bending, bending phenomenon will occur, I would like to annealing treatment. Does the master know the annealing temperature and time?

- 5052, aluminum stamping bending will not break it.

- Q: Is it possible to apply paint to an aluminum sheet roof after it has been installed?

- <p>Yes, you can paint your aluminum sheet roof after installation. However, it's crucial to ensure the surface is clean and free of any contaminants. Use a primer specifically designed for aluminum to enhance adhesion and durability. Apply a high-quality paint suitable for metal surfaces, following the manufacturer's instructions carefully. This process can help protect the roof from weathering and enhance its appearance, but it's recommended to consult with a professional to ensure the best results and longevity of the paint job.</p>

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

0.05-4.0mm Thickness 125 Aluminum Sheets in Spfd Mo for Household

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords