1/2 INCH Seamless steel pipe API 5L/ASTM A 106/ASTM A53GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our products are manufactured strictly according to national and internaional standard, and we take a test. It is with good quality. To draw a conclusion, seamless pipe was usually more easily available than welded pipe.Seamless pipes are considered to be stronger and more durable.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53. We can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

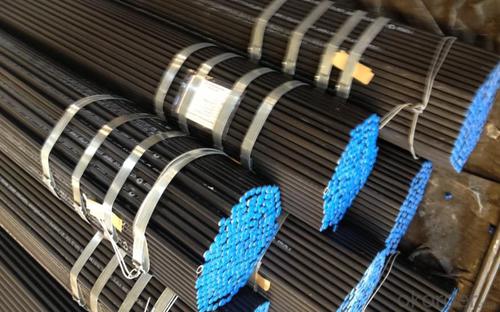

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

Your purchase is guaranteed. If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

②How about the price?

Pls place order immediately. Our quotation is professional.

③Why should you choose us?

All inspection is welcome. We can also offer professional products inquiry, products knowledge train (for agents), fast goods delivery, outstanding customer solution proposals.

6、Seamless Pipe Images:

- Q: Can steel pipes be threaded?

- Yes, steel pipes can be threaded.

- Q: Can steel pipes be used for geothermal heating systems?

- Yes, steel pipes can be used for geothermal heating systems. Steel pipes are commonly used for their durability and ability to withstand high temperatures and pressures. They are suitable for transferring geothermal heat from the ground to the heating system within a building. However, it is important to consider the specific requirements of the geothermal system and consult with professionals to ensure proper installation and compatibility with the system components.

- Q: How do steel pipes perform in high-temperature environments?

- Steel pipes perform well in high-temperature environments due to their excellent heat resistance properties. They can withstand elevated temperatures without losing their structural integrity or strength. Additionally, steel pipes have low thermal expansion, which reduces the risk of deformation or cracking under extreme heat. This makes steel pipes a reliable choice for various applications in industries such as oil and gas, power generation, and chemical processing, where high temperatures are common.

- Q: What are the safety precautions while working with steel pipes?

- Some safety precautions while working with steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is important to ensure the work area is clear of any obstacles or tripping hazards. Workers should be trained in proper lifting techniques to prevent strain or back injuries. Additionally, it is crucial to follow proper procedures for handling and storing steel pipes to prevent accidents and maintain a safe working environment.

- Q: What are the common materials used for pipe fittings in steel pipes?

- Pipe fittings in steel pipes can be made from various materials, including carbon steel, stainless steel, and alloy steel. Carbon steel fittings are popular due to their affordability, strength, and durability, making them suitable for applications in oil and gas, petrochemical, and water distribution systems. On the other hand, stainless steel fittings are highly resistant to corrosion and are commonly used in industries that prioritize hygiene, such as the food and beverage and pharmaceutical sectors. Alloy steel fittings, which consist of elements like chromium, nickel, and molybdenum, are designed to enhance strength and corrosion resistance, making them ideal for high-pressure and high-temperature environments like power plants and chemical facilities. Ultimately, the selection of pipe fitting material in steel pipes depends on the specific requirements of the application and the surrounding conditions.

- Q: What are the different methods of measuring the thickness of steel pipes?

- There are several methods that can be used to measure the thickness of steel pipes, including ultrasonic testing, magnetic particle inspection, eddy current testing, and laser scanning.

- Q: Are steel pipes suitable for high-temperature applications?

- Yes, steel pipes are suitable for high-temperature applications. Steel has excellent heat resistance properties and can withstand high temperatures without deformation or structural failure. Additionally, steel pipes can be specifically designed and coated to enhance their heat resistance, making them ideal for various industrial processes and applications involving high temperatures.

- Q: Can steel pipes be used for underground drainage in acidic soils?

- Steel pipes can be used for underground drainage in acidic soils, but it is important to consider certain factors. Acidic soils can cause corrosion in steel pipes, leading to weakening and potential failure over time. To mitigate this risk, it is advisable to use galvanized steel pipes that are treated with a protective coating to resist corrosion. Additionally, regular inspection and maintenance should be carried out to identify and address any signs of corrosion or deterioration. It is also worth considering alternative materials such as PVC or HDPE pipes, which are more resistant to corrosion in acidic environments. Ultimately, the choice of material should be based on a thorough assessment of the soil conditions, the expected lifespan of the drainage system, and the budgetary constraints.

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes possess several distinct characteristics that set them apart from other pipe types. Primarily, their strength and durability are well-known. They exhibit remarkable resistance to heat, pressure, and corrosion, rendering them suitable for numerous applications. Additionally, their robustness allows them to bear heavy loads and offer an extended service life. One distinguishing feature of steel pipes lies in their versatility. They can be manufactured in various shapes and sizes to fulfill specific project requirements. This adaptability has contributed to their popularity across a diverse range of industries, including construction, oil and gas, water treatment, and manufacturing. Moreover, steel pipes exhibit exceptional thermal conductivity, facilitating efficient heat transfer between different areas. Consequently, they prove suitable for applications involving heating and cooling systems, as well as the transportation of hot fluids or gases. Furthermore, steel pipes are renowned for their resistance to fire. They possess a high melting point and are not easily ignited or conducive to the spread of flames. This characteristic is particularly critical in applications where fire safety is a concern, such as buildings or industrial facilities. Lastly, although steel pipes may entail a higher initial cost compared to other pipe types, their long-term benefits, such as durability and low maintenance requirements, often outweigh the initial investment. Additionally, steel pipes are highly recyclable, making them an environmentally friendly choice. In summary, steel pipes stand out due to their strength, durability, versatility, excellent thermal conductivity, fire resistance, and recyclability. These remarkable qualities establish steel pipes as the preferred option for a wide range of applications across various industries.

- Q: Can steel pipes be used for underground utility lines?

- Yes, steel pipes can be used for underground utility lines. Steel pipes are commonly used for various underground applications, including water, gas, and oil pipelines. They are known for their strength, durability, and resistance to corrosion, making them suitable for underground installations where protection against external elements is required. Additionally, steel pipes are often used in areas with high traffic loads or areas prone to natural disasters, as they provide excellent structural integrity and can withstand heavy loads and external pressures.

Send your message to us

1/2 INCH Seamless steel pipe API 5L/ASTM A 106/ASTM A53GR.B

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords