Aluminum Foil Facing Shielded Copper Cable with Copper Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

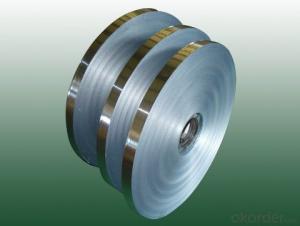

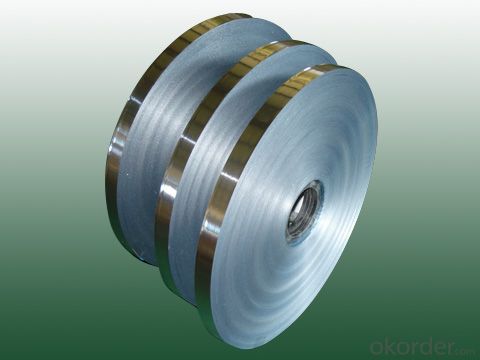

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

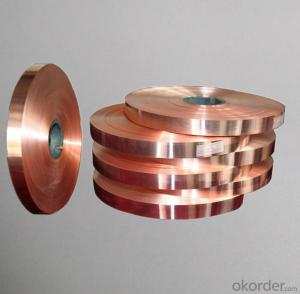

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it safe to use aluminum foil as a facing material for making soups or stews?

- <p>Yes, you can use aluminum foil facing to make soup or stew. Aluminum foil is a common material used in cooking and is safe for contact with food at normal cooking temperatures. It is often used to cover pots to retain heat and moisture, or to create packets for cooking food directly on the heat source. However, it's important to ensure that the foil does not tear or come into direct contact with the heat source, as this could cause it to burn and potentially release aluminum into the food. Always follow safety guidelines and use foil responsibly in cooking.</p>

- Q: This question asks for the proper method of using aluminum foil to wrap food, with emphasis on the correct side of the foil facing outward.

- <p>To wrap food correctly with aluminum foil, you should use the dull side of the foil facing outward, which is in contact with the food. The shiny side has a non-stick surface and is not recommended for direct food contact as it may contain substances that could potentially leach into the food when heated. Start by cutting a piece of foil large enough to fully cover the food. Place the food in the center, then fold the foil over, crimping the edges to seal tightly. This will help retain moisture and heat, and prevent any potential cross-contamination.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for cooking methods like roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap food before roasting or grilling. Aluminum foil is a common and safe material used in cooking, especially for wrapping foods to retain moisture and flavor. It's important to ensure the foil is food-grade and not damaged, as this can affect the food's safety and taste. When using foil, make sure it's sealed properly to prevent juices from leaking and to keep the food moist. Avoid direct contact with the heat source as much as possible to prevent the foil from burning and potentially releasing any harmful substances into the food.</p>

- Q: Can aluminum foil be utilized as a substitute for a frying pan to cook fried rice or stir fry dishes?

- <p>Using aluminum foil to make fried rice or stir fry dishes is not recommended. Aluminum foil is not designed for direct contact with high heat and can melt, leading to uneven cooking and potentially releasing harmful substances into the food. Instead, use a proper non-stick pan or wok designed for high-heat cooking to ensure even heating and prevent food from sticking, which is essential for quick and easy stir frying.</p>

- Q: Is it safe and practical to reuse plastic food wrap materials after cleaning them?

- <p>Reusing food wrap materials after washing them is generally not recommended. Plastic wraps can lose their effectiveness as barriers against bacteria and air after one use. Washing them can also introduce bacteria and may not fully remove any residual food particles. For food safety and hygiene, it's better to use new, clean wraps each time.</p>

- Q: What are some lesser-known applications of aluminum foil in the kitchen?

- <p>Aluminum foil facing has several creative uses in the kitchen beyond just wrapping food. It can be used to cover baking dishes to prevent spills and messes in the oven, line baking sheets for easy cleanup, or create a makeshift roasting bag for cooking meats. It can also be used to sharpen knives by folding it into a book shape and running the blade through the sharp edges, or to create a non-stick surface for cooking by lining molds or baking pans. Additionally, it can be used to scrub pots and pans, removing stuck-on food, or to create a barrier between food and direct heat to prevent burning. These uses showcase the versatility of aluminum foil in the kitchen.</p>

- Q: What are the potential health hazards linked to the use of aluminum foil facing?

- <p>The use of aluminum foil facing in construction or insulation can potentially pose health risks. Inhalation of aluminum dust can lead to respiratory issues, and long-term exposure may contribute to neurological problems. There's also a concern about the leaching of aluminum into food when using aluminum foil for cooking or food wrapping, which some studies suggest could be linked to Alzheimer's disease, although this link is not definitively proven. It's important to handle aluminum foil facing with care, ensuring proper ventilation and protective gear during installation to minimize health risks.</p>

- Q: What are the potential health hazards related to using paper plates in comparison to aluminum foil facing?

- <p>There are generally no significant health risks associated with using paper plates instead of aluminum foil facing. Paper plates are made from food-grade materials and are designed to be safe for contact with food. However, it's important to ensure that the paper plates are free from any harmful chemicals or dyes, and are not contaminated during production or storage. Aluminum foil facing, when used properly, is also safe, but it can leach aluminum into food if heated excessively or used with acidic foods. Both options are generally considered safe, but it's always best to use products from reputable manufacturers and follow usage guidelines.</p>

- Q: Can aluminum foil be shaped into a fish basket?

- <p>Yes, you can use aluminum foil facing to make a fish basket. Start by cutting a large piece of aluminum foil and folding it in half. Create a base by folding the edges up to form a shallow bowl shape. Then, fold the sides up and around, gradually narrowing the width to create the sides of the basket. Continue this process until you reach the desired height, ensuring the sides are sturdy enough to hold the fish. Seal the top with a final fold to complete the basket. This makeshift fish basket can be used for cooking or serving fish, but it's not recommended for heavy use or sharp objects due to the fragility of aluminum foil.</p>

- Q: Is it possible to use aluminum foil facing in the process of making desserts or cakes?

- <p>Yes, you can use aluminum foil facing to make desserts or cakes. It is commonly used for lining baking pans to prevent sticking and to ensure easy removal of the baked goods. Aluminum foil is heat resistant and can be used in the oven, but it's important to avoid direct contact with the heating elements to prevent burning. For best results, use heavy-duty aluminum foil and ensure it covers the bottom and sides of the pan completely.</p>

Send your message to us

Aluminum Foil Facing Shielded Copper Cable with Copper Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords