Aluminum Foil for Printing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

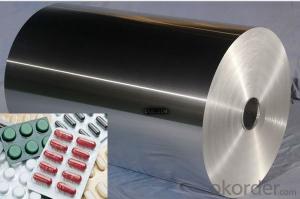

Quick details of Aluminium Foil for Printing

Alloy: 1235/8011/8079

Temper: O

Specifications of Aluminium Foil for Printing

Thickness & Tolerance: 0.006 mm-0.02mm (+/-6%)

Width & Tolerance: 200 - 1650 mm (+/-1 mm)

Mechancial Properties: Tensile Strength(U.T.S)≥40Mpa, Elongation≥1%

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Aluminium Foil for Printing

For Printing

Packaging & Delivery of Aluminium Foil for Printing

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to repurpose or reuse old aluminum foil for various uses?

- <p>Yes, old aluminum foil can be repurposed for various uses. It can be recycled, used as a makeshift scrubber for cleaning, or as a reflector for grilling. You can also use it to cover food for storage or as a barrier in gardening to deter pests. However, it's important not to reuse foil that has held acidic or sugary foods, as it can corrode and release aluminum into the food. Always ensure the foil is clean and in good condition before repurposing.</p>

- Q: Is it possible to create jewelry using pure aluminum?

- <p>Yes, pure aluminum can be used to make jewelry, but it's not commonly used for fine jewelry due to its lower value and potential for oxidation. While it is lightweight and affordable, it lacks the luster and durability of precious metals like gold, silver, or platinum. Aluminum can tarnish and may cause allergic reactions in some individuals. It is more commonly used in costume jewelry or for specific designs where its properties are advantageous.</p>

- Q: This question asks about the amount of energy needed to produce aluminum.

- <p>The energy required for the production of aluminum is substantial. Producing one ton of aluminum typically requires around 15-25 kilowatt-hours of electricity, largely due to the process of electrolysis, which is used to extract aluminum from its ore, bauxite. This high energy consumption is a significant factor in aluminum production costs and environmental impact. The energy required can vary based on the efficiency of the smelting process and the source of electricity used.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of medical devices like stents or implants?

- <p>Aluminum is not typically used in medical devices such as stents or implants due to its potential toxicity and lack of biocompatibility. Medical-grade materials like stainless steel, titanium, and various biocompatible polymers are preferred for their strength, durability, and ability to be safely integrated with human tissues. Aluminum can cause adverse reactions in the body, and its use in medical devices is generally avoided to prevent such complications.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: What are the negative aspects or drawbacks of using aluminum?

- <p>Aluminum has several disadvantages. It is a non-magnetic material, which limits its use in applications requiring magnetic properties. Aluminum is also less dense than many other metals, making it less suitable for heavy-duty applications. It can be toxic in certain forms, such as aluminum salts, and has been linked to health issues when ingested in large amounts. Additionally, aluminum's low melting point can be a disadvantage in high-temperature environments. Lastly, the production process of aluminum is energy-intensive and can contribute to environmental pollution.</p>

- Q: Is it possible to use pure aluminum for crafting jewelry or sculptures?

- <p>Yes, you can use pure aluminum for jewelry making or sculpture, but it's not as common as other metals due to its lower melting point and softer nature. Pure aluminum is lightweight, affordable, and easy to work with, making it suitable for certain types of designs. However, it's not as durable or resistant to scratches as metals like silver or gold, and it may require special care to maintain its appearance. It's also important to consider the potential for allergic reactions, as some people are sensitive to aluminum.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

- Q: What specific rules or guidelines are there for incorporating aluminum in construction projects?

- <p>Yes, there are special regulations for using aluminum in construction projects. These regulations vary by country and region but generally include standards for material properties, structural integrity, fire resistance, and environmental impact. For instance, the American Society for Testing and Materials (ASTM) and the Aluminum Association provide guidelines for aluminum usage in construction. Compliance with building codes is crucial, and these codes often specify the grades of aluminum, allowable stress values, and methods of joining. Additionally, considerations for corrosion resistance, thermal expansion, and recycling potential are important. It's essential to consult local building codes and industry standards to ensure compliance when using aluminum in construction.</p>

- Q: This question asks for examples of alloys that include aluminum as one of their components.

- <p>Aluminum is a versatile metal that forms many alloys, enhancing properties like strength, corrosion resistance, and electrical conductivity. Some common aluminum alloys include: 1. 6061, used in aircraft structures and automotive parts due to its good mechanical properties and machinability. 2. 2024, known as 'Alclad', is strong and used in aircraft structures. 3. 7075, one of the strongest aluminum alloys, used in aerospace and military applications. 4. 3003, used for cooking utensils and chemical equipment due to its good corrosion resistance. 5. 5052, used in marine applications and food processing equipment for its excellent corrosion resistance. These alloys are widely used in various industries due to their unique properties.</p>

Send your message to us

Aluminum Foil for Printing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords