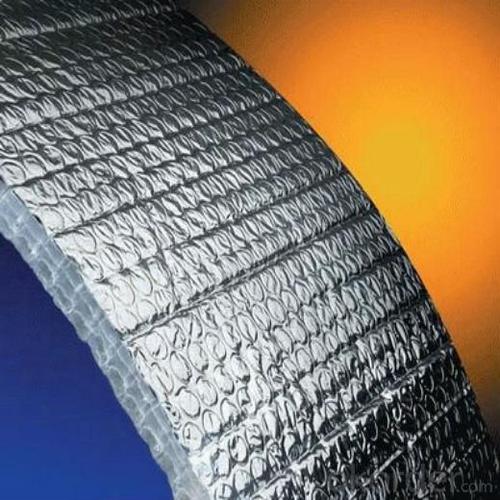

Aluminum Insulation Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Detials of Aluminium Foil for Insulation

Alloy: 1100 / 8011

Temper: O/H22/H24

Specifications of Aluminium Foil for Insulation

Thickness & Tolerance: 0.05 mm - 0.2 mm (+/-6%)

Width & Tolerance: 200 - 1650 mm (+/-1 mm)

Lacquer: Epoxy/piyurethane coating to stick with PU foam

Primer: Anti bacterial primer

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Aluminium Foil for Insulation

For air conditioning system

Packaging & Delivery of Aluminium Foil for Insulation

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a component in battery technology?

- <p>Yes, aluminum can be used in batteries. Aluminum-air batteries are a type of metal-air battery that uses aluminum as the anode. These batteries have a high energy density and are lightweight, making them suitable for certain applications. However, they also have challenges such as the need for a specific electrolyte and issues with aluminum corrosion, which limit their practical use compared to more common battery technologies like lithium-ion batteries.</p>

- Q: This question asks for methods to determine the presence of aluminum in an alloy.

- <p>To determine if an alloy contains aluminum, one can use various analytical techniques. A common method is spectroscopy, which can identify the presence of specific elements by analyzing the wavelengths of light absorbed or emitted. Another approach is the use of a spark test, where a sample is struck against a grinding wheel to produce sparks; the color and pattern of these sparks can indicate the presence of aluminum. Chemical tests, such as the reaction with sodium hydroxide, can also be used, as aluminum reacts with NaOH to produce hydrogen gas. Lastly, X-ray fluorescence (XRF) is a non-destructive technique that can accurately determine the elemental composition of an alloy, including aluminum content.</p>

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: What are the potential dangers of utilizing high-purity aluminum powders in industrial settings?

- <p>Yes, there are risks associated with using high-purity aluminum powders in manufacturing processes. These powders can be highly reactive, especially when in fine particle form, and pose a risk of dust explosions if they come into contact with an ignition source. Additionally, aluminum dust can be a respiratory hazard, potentially causing health issues if inhaled. Proper handling, storage, and safety measures are crucial to mitigate these risks.</p>

- Q: Is there any risk to health from consuming food wrapped in aluminum foil?

- <p>Eating food wrapped in aluminum foil generally does not pose significant health concerns under normal circumstances. Aluminum is a stable element and does not leach easily into food at room temperature. However, at high temperatures, such as during grilling or baking, small amounts of aluminum might migrate into food. Most studies suggest that the amount of aluminum ingested from food wrapped in foil is minimal and not harmful. Nonetheless, it's advisable to avoid wrapping acidic foods or using foil in direct contact with food at high temperatures to minimize any potential exposure.</p>

- Q: Explain the interaction between aluminum and water, including any chemical reactions or properties.

- <p>Aluminum and water do not react directly under normal conditions. Aluminum is a reactive metal, but it is protected by a thin layer of aluminum oxide that forms on its surface when exposed to air, which prevents further reaction with water. This oxide layer is stable and acts as a barrier, making aluminum resistant to corrosion. However, in certain conditions, such as when aluminum is in contact with water and an electrolyte, it can lead to a process known as electrochemical corrosion. Additionally, aluminum can react with steam at high temperatures to form aluminum oxide and hydrogen gas.</p>

- Q: This question asks for common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. Some applications include: 1) Food and beverage cans for preserving food and drinks. 2) Aluminum foil used for cooking and food storage. 3) Construction materials, such as window frames and roofing. 4) In transportation, like car parts and airplane components to reduce weight. 5) Electrical wiring due to its high conductivity. 6) Household items like pots and pans, and furniture. 7) Packaging materials for various products. 8) In sports equipment like bicycle frames and tennis rackets. These applications highlight aluminum's versatility and importance in everyday life.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional process?

- <p>Yes, aluminum can be recycled using different processes. While the conventional process involves melting and recasting, alternative methods include mechanical recycling, which involves shredding and reusing aluminum without melting, and chemical recycling, which breaks down aluminum into its base elements and reassembles them into new products. These methods can be more energy-efficient and environmentally friendly, depending on the specific circumstances and technologies used.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

- Q: Is there a more environmentally friendly method for recycling aluminum?

- <p>Yes, aluminum can be recycled in a more environmentally friendly way. The process of recycling aluminum is already quite efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. However, further improvements can be made by optimizing recycling processes, reducing transportation emissions, and increasing the use of recycled aluminum in new products. Additionally, implementing closed-loop recycling systems where aluminum is continuously recycled without loss in quality can minimize waste and environmental impact. Educating consumers about the importance of recycling and improving collection systems can also contribute to more sustainable aluminum recycling practices.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 250 Million |

| Main Markets | Mid East; North America |

| Company Certifications | ISO 14001:2004;FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Insulation Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords