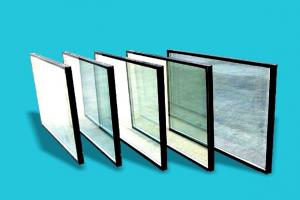

Insulating Glass 2-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulating Glass is made up of two or more pieces of glass which are separated by metal frames, its edge is sealed with the glue by way of jointing and welding.

Features:

1. Heat preservation and energy conservation

2. Anti-frost and anti-dewing

3. Sound insulation

4. The aluminum bar is bent automatically. Automatic molecular-sieve filling system, vertical coupling and vertical automatic sealing can guarantee the production of high-quality insulating glass technically.

5. Compared with common insulating glass, the sealing is reliable for homogenous coating with no bulbs between the layers.

6. good appearance, good dew point

Specifications:

Thickness: 2-19mm

Size:

2500*5000mm(Max)

250*300mm(Min)

Applications:

Insulating Glass is mainly used as building glass in curtain wall, glass doors and windows, etc.

- Q: The use of quartz sand

- Derived from various magmatic rocks, sedimentary rocks and metamorphic rocks, less heavy minerals, associated minerals are feldspar, mica and clay minerals. There are two kinds of sedimentary rock genesis and metamorphic origin, the former is not obvious between clastic particles and cement, and the latter refers to quartz rocks with deep metamorphic and pure quality. The quartz veins are formed by hydrothermal action, almost all of them are composed of quartz, and they are compact and massive structures.The mineral content of quartz sand varies greatly, mainly quartz, followed by feldspar, mica, cuttings, heavy minerals and clay minerals.

- Q: What kind of raw materials should be used in making FRP?

- The raw material of glass fiber reinforced plastic is divided into two kinds: reinforced material and base materialThe reinforced material of glass fiber reinforced plastic is composed of glass fiber and its fabric. It is the main load-bearing component material of glass fiber reinforced plastics, and has a direct impact on the strength and stiffness of FRP

- Q: Ask the glass making processWhat kind of material is the glass made of? What material is good?

- Glass: a liquid material is transparent, forming a continuous network structure in the melt, silicate nonmetalmaterials cooling process viscosity increases gradually and hardening without crystallization. The main ingredient is silica. Widely used in building, but to every wind light.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Because I work in the glass curtain wall project, only know raw materials to do a glass curtain wall material impact strength test before installing the unit model, in a special laboratory, no experimental requirements should be in the process of construction, the construction of the end of may do some water resistance experiment. Hope to be of help to you!

- Q: What are the raw materials for low dielectric glass fiber?

- Glass fiber is divided into different grades according to its composition, properties and uses. According to the provisions of the standard level (see table), E glass fiber is most widely used, widely used in electrical insulating materials; special fiber grade S, while the output is small, but very important, because it has super strength, mainly used for military defense, such as bullet proof box; C level more than E with chemical resistance in the battery isolation plate, chemical filter; a basic glass fiber reinforced materials used in the production.The main component of glass fibre and its main components are silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide, depending on the amount of alkali content in glass, can be divided into non alkali glass fiber (Na2O 0% ~ 2%, which belongs to the aluminum borosilicate glass), glass fiber (8% ~ sodium sodium calcium silicate glass 12%, a boron containing or not containing boron) and high alkali glass fiber (Na2O 13%, sodium calcium silicate glass).

- Q: Which is the best solar water heater tube?

- The color of the vacuum heat collecting tube is mainly blue and black, and the overall chromatic aberration is small. But black does not indicate the quality of vacuum heat collecting tube is good, because some manufacturers in order to cover up variegated, often made of pure black film. In fact, there is a certain error in the color of the vacuum heat collecting tube, which is unavoidable, and does not affect the heat collecting efficiency of the vacuum heat collecting tube.

- Q: How is glass made, raw material proportioning?

- There are many kinds of glass, different kinds, different uses, and different ingredients.

- Q: Who can tell me the raw material and function of the flashy glass?

- The roll of the roll is rotated, and the glass belt is pulled out of the tin groove into the annealing furnace. After annealing and cutting, the flat glass product is obtained.

- Q: What kinds of ingredients are the glass?

- Flint glass is a high density and high refractive index glass. It can be produced by lead instead of calcium in sodium glass in molten glass. It is suitable for making optical glass and carved glass products. The coefficient of thermal expansion of hard glass is very high

- Q: Failure reasons and solutions of insulating glass.

- The production of hollow glass raw material quality; key factors affect the service life of hollow glass sealant is ageing resistance and desiccant adsorption capacity, and the determining factor is the performance of sealant. Because no matter how much the desiccant adsorption capacity, inside the hollow glass after a certain limit, when the hollow glass desiccant completely saturated, again good desiccant also unable to water vapor adsorption, then the hollow glass is invalid. Only when the sealant has good sealing performance, moisture permeability coefficient is low, the amount of water vapor into the hollow glass rarely, and keep this state, only rarely can guarantee the hollow glass desiccant inside gas drying, so as to ensure the effect of hollow glass.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | Southeast Asia; Mid-East; Africa |

| Company Certifications | CE;RoHS;ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Insulating Glass 2-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches