Alkali Resistant Fiberglass Mesh Cloth Roll Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Roll Coating Alkali Resistant

Fiberglass Mesh Roll Coating Alkali Resistant is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

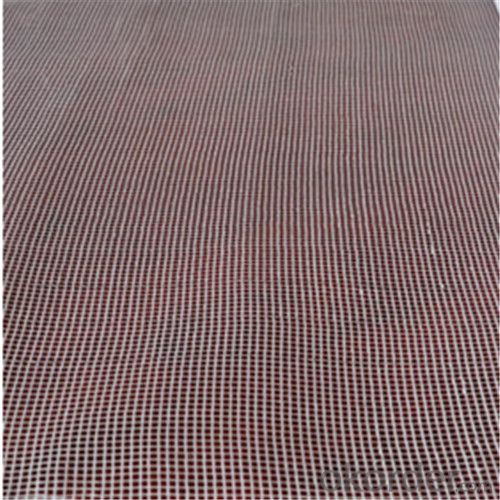

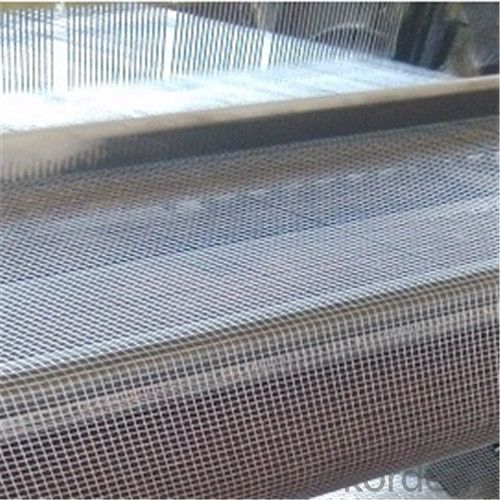

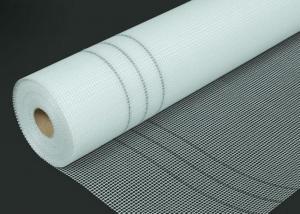

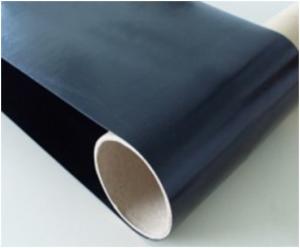

Image of Fiberglass Mesh Roll Coating Alkali Resistant

Specifications of Fiberglass Mesh Roll Coating Alkali Resistant

Place of Origin: China (Mainland)

Brand Name: CMAX

Application: Wall Material, Marble Slab Reinforcement

Width: 1M-2M

Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Weight: 40gsm to 200gsm

Length/ roll: 50m-100m, Special spec can be customized

Weave Type: Leno, Plain Woven

Yarn Type: C-Glass, E-Glass

Alkali Content: Medium Alkali

Standing Temperature: 500℃

Item Number | Yarm (tex) | Mesh Size | Density Count/625px | Finished Weight(g/m2) | Tensile StrengthX500px | Woven Structure | Content of resin% (≥) | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||||

TP5x5-70 | 45x2 | 200 | 5 | 5 | 5 | 5 | 70 | 550 | 850 | Leno | 16 |

TP5x5-80 | 67x2 | 200 | 5 | 5 | 5 | 5 | 80 | 700 | 850 | Leno | 16 |

TP5x5-90 | 67x2 | 250 | 5 | 5 | 5 | 5 | 90 | 700 | 1050 | Leno | 16 |

TP5x5-110 | 100x2 | 250 | 5 | 5 | 5 | 5 | 110 | 800 | 1050 | Leno | 16 |

TP5x5-125 | 134x2 | 250 | 5 | 5 | 5 | 5 | 125 | 1200 | 1300 | Leno | 16 |

TP5x5-135 | 134x2 | 300 | 5 | 5 | 5 | 5 | 135 | 1300 | 1400 | Leno | 16 |

TP4x4-135 | 100x2 | 250 | 4 | 4 | 6 | 6 | 135 | 1000 | 1300 | Leno | 16 |

TP5x5-145 | 134x2 | 360 | 5 | 5 | 5 | 5 | 145 | 1200 | 1300 | Leno | 16 |

TP4x5-150 | 134x2 | 300 | 4 | 5 | 6 | 5 | 150 | 1300 | 1300 | Leno | 16 |

TP5x5-160 | 134x2 | 400 | 5 | 5 | 5 | 5 | 160 | 1450 | 1600 | Leno | 16 |

TP4x4-160 | 134x2 | 300 | 4 | 4 | 6 | 6 | 160 | 1550 | 1650 | Leno | 16 |

TP4x5-165 | 134x2 | 350 | 4 | 5 | 6 | 5 | 165 | 1300 | 1300 | Leno | 16 |

Packing and Delivery of Fiberglass Mesh Roll Coating Alkali Resistant

Package: Each roll is wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order

Application/Usage of Fiberglass Mesh Roll Coating Alkali Resistant

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Roll Coating Alkali Resistant

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Roll Coating Alkali Resistant?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Roll Coating Alkali Resistant?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Roll Coating Alkali Resistant?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Roll Coating Alkali Resistant?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q: What are the transverse and longitudinal tensile forces of alkali resistant glass fiber mesh cloth?

- The reason: the current domestic weaving factory method or pre roll beam weaving, and net fabric warp yarn and weft yarn is usually, roving, the intensity is greater than the warp weft. Secondly, to weave is usually weaving, woven to the continued strength of more than.

- Q: Method for sampling alkali proof glass fiber mesh cloth

- The amount of cement, sand barrels after weighing pour the mixture iron grey trough, mix according to the mixture ratio and binder is added for mixing, stirring to be uniform, to avoid segregation, a gruel. Water can be added according to workability.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- What is more the incineration of waste mesh, which is of serious pollution damage behavior of soil air, acrylic mesh after high temperature can produce pungent odor, destroying the respiratory system and strong material, the core material is flame retardant fiberglass mesh product is burning up, so it is a serious pollution of soil caused by.

- Q: Self-adhesive fiberglass mesh

- Self adhesive mesh and EPS mesh than the general viscous grid has the characteristics and general mesh fabric. But than the general mesh more viscous soft, moderate viscosity, uniform coating, adhesive does not appear in some places, some places less adhesive at the time of construction, to avoid the "bulge" phenomenon.

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- Add a bit of gum, and the mesh will become harder

- Q: Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- This product and people engaged in the industry of external wall insulation pot imitation gold mesh fabric is very familiar, but exactly how this product is really not much here to explain imitation gold mesh pot is to be defined.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The inner wall heat preservation alkali resistant glass fiber net is made of alkali or alkali free glass fiber mesh cloth as base material, and then modified by coating acrylic ester copolymer liquid. It has the characteristics of light weight, high strength, temperature resistance, alkali resistance, waterproof, corrosion resistance, anti cracking and dimensional stability. It can effectively avoid the surface tension, shrinkage and cracking caused by external forces of the plastering layer, and the light mesh cloth is often used for wall renovation and internal wall insulation.

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Don't spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

Send your message to us

Alkali Resistant Fiberglass Mesh Cloth Roll Coating

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords