Venta De Geomembrana Resistancia Negra HDPE Para Forro De Estanque Con Precio Asequible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Resistance Black HDPE Geomembrane for Pond Liner:

Our high density polyethylene (HDPE) geomembranes provide an impermeable barrier against a wide range

of solids and liquids. They exhibit excellent chemical and UV resistance, impermeability, and high yield and

welded seam strengths, which is widely used as the liner.

Main Features of Resistance Black HDPE Geomembrane for Pond Liner:

1.Long life, anti-aging, roof material can be more than 20 years, underground can be more than 50 years.

2. Good tensile strength, high elongation.

3. Good high/low temperature flexibility

4.Easy to construct, no pollution.

5. Good anti-corrosive ability, can be used in special area

6.Various colors are available

Specifications of Resistance Black HDPE Geomembrane for Pond Liner:

a) Density ≥ 0.94g/m²

b) Tensile Strength ≥25Mpa

c) Elongation at Break ≥ 550%

d) Right-angled Tear ≥ 110N/mm

e.)Puncture Strength ≥ 550N

f.) Permeability Coefficient ≤1.0xe-13g.cm/(cm2.S.Pa)

g.) -70oC Low Temperature Impact Brittle Property: good.

h.) Chemical Resistance: at 80oC, marinated in 5g/L Nacl for a long time, it will not erode or swell.

Applications of Resistance Black HDPE Geomembrane for Pond Liner:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

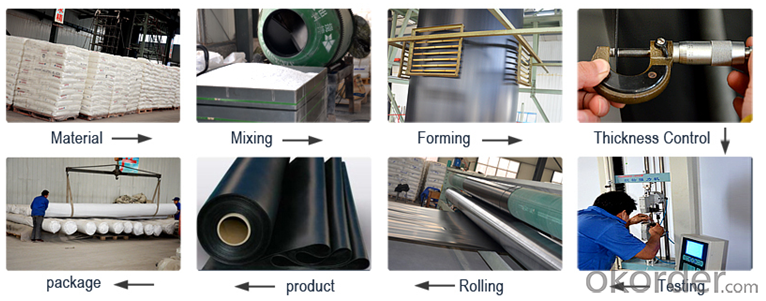

IMages of Resistance Black HDPE Geomembrane for Pond Liner:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Is the notebook protective film good?

- It is best to prepare an adhesive tape and fold it in the shape as the figure below (used for sticking to dust). Before pasting, first shut down the power. You'd better post some soft cushion in the bottom of the screen, because the screen of most computers may not be able to fold to 180 degrees. It is best to fix the screen well. First clean the screen, and it must be cleaned thoroughly, otherwise there is dust left and small bubbles will appear. First take out the screen film to make sure that its size is the same with that of the screen. And after confirmation, you will see there are stickers marked 1 and 2 on the protective film. First fold the sticker marked 2 as the figure below. Then turn over the screen film. The side marked 1 should be adhered to the screen and it is ok to first uncover it a little bit.

- Q: What's the stick membrane methods of waterproof mobile?

- Check your phone: Check whether the appearance of phone is damaged, power on, and check whether the phone is operating normally. Such as call, the phone volume buttons, play music, check the horn player ... and so if everything is normal. Registration Phone: before coating, register each phone model. 3 Cleaning Phone: before coating, you can use suction head to clean the dust in each gap, and clean the external phone with cleanser. drop the cleanser on the surface of phone, wipe the surface to clean, and clean the external parts Removing the back cover: the one that the rear cover can be removed, or must be removed, remove the SIM card, memory card, (Note: If the battery removed has serious eccentricity or too large gap, you can not remove the battery) Choose fixture: select the desired size in accordance to each phone's size,(check to ensure no gaps), the fixture can not be too tight so as not to crush the screen (note that the phone screen should be up), please notice all the keys on your phone, holes need to be avoided, can not be covered, avoid impacting the effect of coating, coating can be processed after finishing checking. launching switch: Press the start switch, lights up(as the figures in picture..), wait 3 seconds and machine starts to work, press OFF means to stop working, wait 3 seconds the machine starts to work, time of plating a mobile phone is about 3-4 minutes, the machine stops automatically after finishing coating, wait about 5 seconds air pressure drops, then open the sealed windows.

- Q: The methods for sticking mobile phone film?

- 1. The environment: the place that need to be pasted with film should be bright enough. And the ligh indoors is too weak, the table lamp should be prepared so as to look the details clear. 2. To wash hands: The dust and grease on your hands should be cleaned carefully.

- Q: Are geomembranes suitable for use in desalination plants?

- Yes, geomembranes are suitable for use in desalination plants. Geomembranes are impermeable and durable materials that can effectively contain and separate liquids, making them ideal for lining and sealing desalination plant basins, ponds, and reservoirs. They provide a reliable barrier against leaks, thereby preventing the loss of freshwater or contamination of surrounding soil and groundwater. Additionally, geomembranes are resistant to chemicals, UV radiation, and extreme temperatures, which are common in desalination plants. Overall, their versatility and performance make them a suitable choice for use in desalination plants.

- Q: What are the chemical resistance properties of geomembranes?

- Geomembranes are synthetic materials that exhibit excellent chemical resistance properties. They are designed to withstand exposure to a wide range of chemicals, including acids, bases, solvents, and other aggressive substances. The chemical resistance of geomembranes is primarily due to their composition, which often includes high-density polyethylene (HDPE) or other durable polymers. These materials are resistant to degradation, corrosion, and permeation, making geomembranes an ideal choice for containment applications in various industries, such as waste management, mining, and oil and gas.

- Q: which kind of imitation wood film is better?

- good imitation wood film materials include: PET, PVC, acrylic. characteristic: it can be lettering, bar cutting, photo printing, screen printing 1, light emitting film made by PVC materials can be photo printing, PET emitting film can be lettering, bar cutting, acrylic light emitting film is suitable for screen printing. 2, it has some salt water resistance, detergent resistance (it can be cleaned with detergent). 3, it has excellent heat resistance, cold resistance, suitable for the environment of -20 ~ 50 ℃. 4, the light emitting film has good phisical and mechanical properties. 5, the light emitting film is a sticky, it can stick to the general surface.

- Q: How do geomembranes handle differential settlement?

- Geomembranes are flexible materials that can accommodate differential settlement by conforming to the changes in the underlying soil or substrate. They are designed to distribute and absorb the stress caused by settlement, minimizing the risk of damage or failure. The flexibility and adaptability of geomembranes allow them to maintain their integrity and performance even in areas with significant settlement.

- Q: How to adhere film to the glass window?

- A. Preparatory work and installation of architectural membrane pasting: 1. Preparations before installation a) Learn the specific conditions of the window to be pasted membrane in detail, and estimate specific items for site cleaning, and the size and quantity of the window membrane needed cutting; b) Determine the construction?method according to the window membrane type chosen by the customer and characteristics of the the glass; c) Check whether the installation tools are normal, and check if the "blade" of the water wiper is flat and smooth, and if there is any gap existent. Check if the cleaning scraper knife is sharp, and if there is any gap or sawtooth existent; d) Check if the cleaning and installation towel is clean, if the waterproof membrane is clean and intact; e) Prepare the film-on and cleanout fluid well; 2. Installation of window membrane: A. Advance preparations for the construction site. a) In the construction site, remove the curtains, blinds, and all other objects near the window carefully, and make them go back to the original state when the window membrane installation is completed. Try to leave more space for equipment placement. If the construction site is located within an office or store, please make sure that the cleaning work in advance will not interfere with the customer's normal business operations; b) Do a good job in on-site waterproof and cleaning, laying of waterproof membrane, and work overalls and shoe covers wearing;

- Q: What are the advantages of using geomembranes in mining tailings ponds?

- There are several advantages of using geomembranes in mining tailings ponds. Firstly, geomembranes act as a barrier, preventing the leakage of potentially harmful chemicals and contaminants into the surrounding environment, thus protecting water resources and ecosystems. Secondly, they minimize the risk of groundwater contamination by creating a reliable containment system. Additionally, geomembranes offer increased durability and resistance to punctures, ensuring the long-term integrity and stability of the tailings pond. Finally, using geomembranes allows for more efficient management of tailings, reducing the required footprint of the pond and enabling easier monitoring and maintenance.

Send your message to us

Venta De Geomembrana Resistancia Negra HDPE Para Forro De Estanque Con Precio Asequible

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords