Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

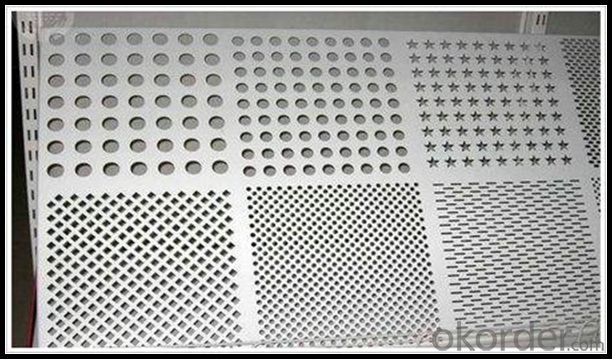

1. Structure of Mill Finished Aluminium Sheet for Punching Description

Mill Finished Aluminium Sheet for Punching is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Sheet for Punching

Mill Finished Aluminium Sheet for Punching | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Sheet for Punching

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Sheet for Punching

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Sheet for Punching

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

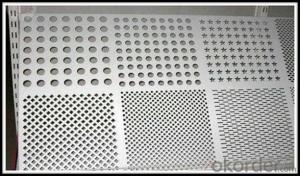

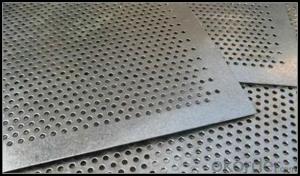

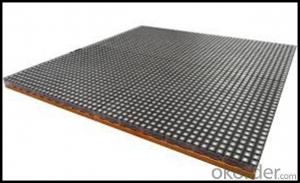

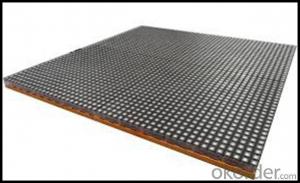

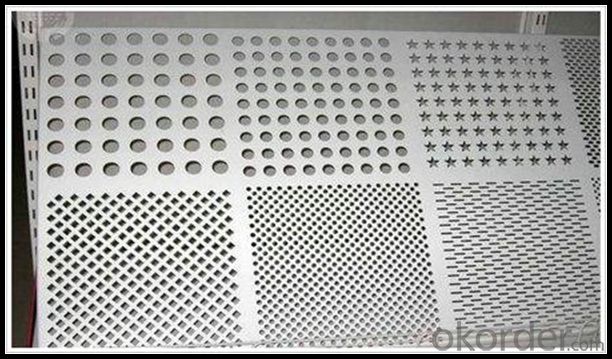

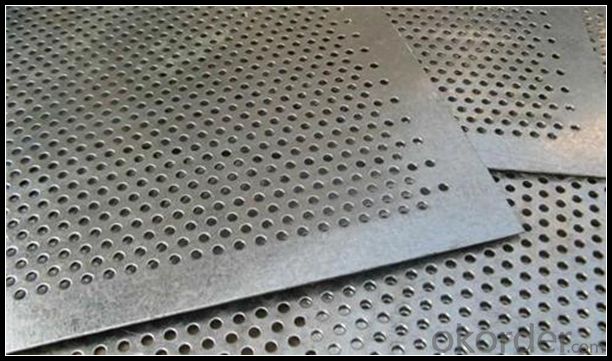

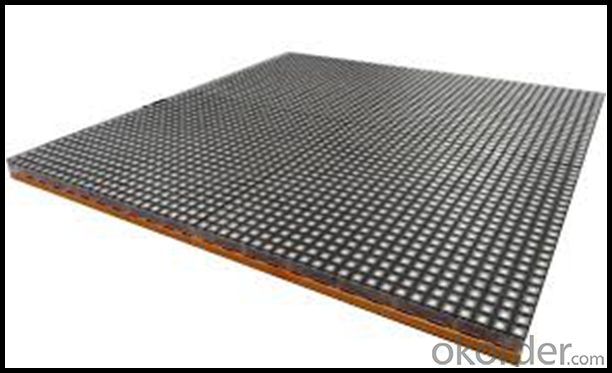

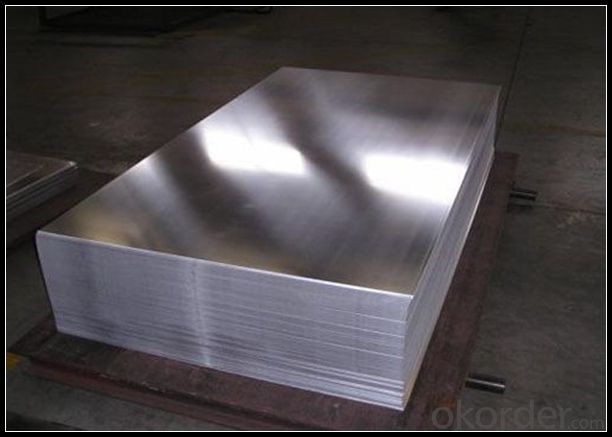

6. Image of Mill Finished Aluminium Sheet for Punching

7. Package and shipping of Mill Finished Aluminium Sheet for Punching

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the role of aluminum coils in the construction of ships?

- The marine industry heavily relies on aluminum coils for the construction of ships. These coils are essential in manufacturing various ship components and structures. The lightweight nature of aluminum coils is a significant advantage in ship construction. Compared to traditional steel, aluminum is much lighter, resulting in improved fuel efficiency and overall performance of the ship. This is particularly beneficial for larger vessels, as reducing weight helps minimize energy consumption and operating costs. Furthermore, aluminum coils offer outstanding resistance to corrosion, making them ideal for the harsh marine environment. Ships constantly face exposure to corrosive saltwater, which can deteriorate metal materials. By utilizing aluminum coils, shipbuilders can ensure that their vessels are well-protected against rust and corrosion, ultimately extending their lifespan and reducing maintenance needs. Additionally, aluminum coils are easily shaped and formed into various structures, providing shipbuilders with greater design flexibility. This versatility allows for the creation of intricate ship components like hulls, superstructures, and bulkheads. Aluminum's excellent weldability also simplifies the process of joining different sections of the ship, resulting in more efficient and streamlined construction. Moreover, aluminum is a highly sustainable material. It can be recycled without any loss in quality or performance, making aluminum coils an environmentally friendly choice for ship construction. This aligns with the increasing focus on sustainability in the industry. In conclusion, aluminum coils play a multifaceted role in ship construction. They offer lightweight, corrosion-resistant, and easily formable materials that contribute to improved fuel efficiency, durability, and design flexibility. Additionally, their recyclability makes them an environmentally conscious option. Overall, aluminum coils are a vital component in building efficient, durable, and sustainable ships.

- Q: Can aluminum coils be welded?

- Absolutely! Welding aluminum coils is indeed possible. Aluminum is a material known for its exceptional weldability and is widely utilized in various industries because of its lightweight nature and resistance to corrosion. There are numerous welding techniques available for joining aluminum coils, including TIG welding (tungsten inert gas), MIG welding (metal inert gas), and even laser welding. Nevertheless, it is crucial to bear in mind that welding aluminum can be more demanding compared to other metals due to its high thermal conductivity and low melting point. As a result, it is imperative to employ appropriate welding methods and equipment, such as specialized aluminum welding wire and shielding gases, to guarantee successful and top-notch welds.

- Q: Can the color coated aluminum roll be bent easily and won't break?

- Weathering resistance. The weight of a unit volume is the lightest of all metal materials. It is widely used in fields such as pigments, balcony packaging, and is not susceptible to corrosion. It is durable and beautiful in appearance. Specially applied to the interior of public places, colour coated aluminium rolls have become one of the most popular top decorative materials: polyester coated aluminum rolls (PE). According to the surface film forming structure, fluorocarbon coating can be divided into two kinds: traditional fluorocarbon and nano fluorocarbon coating. The biggest advantage is that the strength of the fluorocarbon coating is incomparable. It is a new type of material which has recently emerged in the field of doors and windows.

- Q: What are the different grades of aluminum used in coils?

- There are several different grades of aluminum commonly used in coils, including 1100, 3003, 5052, and 6061. Each grade has its own unique characteristics and properties, making them suitable for different applications. For example, 1100 aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it ideal for heat exchangers and fins. On the other hand, 5052 aluminum offers good formability and moderate strength, making it commonly used in automotive and marine applications. Lastly, 6061 aluminum is a versatile grade with excellent strength-to-weight ratio, making it suitable for structural components and aerospace applications.

- Q: Is it possible to utilize aluminum coils in the automotive industry?

- <p>Yes, aluminum coils are widely used in the automotive industry. They are employed in various applications such as engine parts, heat exchangers, and body panels due to their lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum's recyclability and energy efficiency in production also contribute to its popularity in vehicle manufacturing.</p>

- Q: Are there any limitations to the maximum coil diameter of aluminum coils?

- Yes, there are limitations to the maximum coil diameter of aluminum coils. The maximum coil diameter is determined by several factors including the type and thickness of the aluminum, the equipment used for coiling, and the intended application of the coil. Generally, larger coil diameters can be achieved with thinner and more ductile aluminum alloys. However, as the coil diameter increases, it becomes more challenging to maintain the structural integrity of the coil and prevent deformation, wrinkling, or damage during handling and transportation. Additionally, the equipment used for coiling may have limitations in terms of the maximum diameter it can handle. Therefore, it is important to consider these factors when determining the maximum coil diameter for aluminum coils.

- Q: How are aluminum coils used in the manufacturing of appliances?

- Aluminum coils find widespread use in the manufacturing of appliances because of their unique properties and versatility. Primarily, they are employed in the production of heat exchangers, which serve as essential components in appliances like refrigerators, air conditioners, and heaters. One of the key advantages of aluminum coils lies in their remarkable thermal conductivity. This attribute enables them to efficiently transfer heat from one area to another, making them an ideal choice for applications involving heat exchange. In appliances, aluminum coils assist in the cooling or heating processes by transferring heat between the refrigerant or coolant and the surrounding air or water. Additionally, aluminum coils offer superior corrosion resistance in comparison to other metals, rendering them highly suitable for appliances that come into contact with moisture or other corrosive substances. This property guarantees the durability and longevity of the appliances, as the coils are less likely to rust or corrode over time. Moreover, the lightweight nature of aluminum coils contributes to the overall efficiency of appliances. It reduces the energy required for transportation and installation, thereby making it a more sustainable option. Furthermore, the lightweight coils allow for more compact designs, maximizing space utilization in appliances. Another advantage of aluminum coils is their malleability. They can be easily shaped and formed into various sizes and configurations, enabling customized designs that cater to specific appliance requirements. This design flexibility empowers manufacturers to create efficient heat exchangers that fit within the limited space available in appliances. In conclusion, the excellent thermal conductivity, corrosion resistance, lightweight nature, and malleability of aluminum coils make them a preferred choice for use in appliances. These properties make them particularly well-suited for heat exchangers, which play a crucial role in appliances requiring efficient cooling or heating processes.

- Q: I need to write as many interesting facts as i can about aluminum for a thing for school, any help?

- Aluminum, Motorcycle engine aluminum radiator made by precise die casting

- Q: What is the typical lifespan of an aluminum coil?

- The typical lifespan of an aluminum coil can vary depending on various factors such as the quality of the coil, its usage, maintenance, and exposure to environmental conditions. However, on average, an aluminum coil can last anywhere from 20 to 30 years with proper care and maintenance.

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Yes, aluminum coils are generally more cost-effective compared to copper coils. Aluminum is cheaper and more abundant than copper, which makes it a more affordable option for various applications. Additionally, aluminum coils require less maintenance and have a longer lifespan, reducing overall costs in the long run.

Send your message to us

Mill Finished Aluminum Coil Plate for Punching

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords