Centering And Shuttering Form Work

Centering And Shuttering Form Work Related Searches

Striking Formwork Moving Formwork Gliding Formwork Rough Formwork Conventional Formwork System Form Construction Materials For Formwork System Formwork Advanced Concrete Formwork Engineered Formwork System Rammed Earth Formwork Column Clamps Formwork Form Work Concrete Requirements Of Good Formwork Concrete Formwork System Concrete Pit Formwork Fabric Formwork Liners And Covers Formwork System Gass Formwork Green Formwork Strongback Formwork Formwork Props Window Closers Concrete Boxing Formwork Circle Concrete Forms Foundation Formwork Sawn Formwork Permanent Formwork System Metal Formwork SystemCentering And Shuttering Form Work Supplier & Manufacturer from China

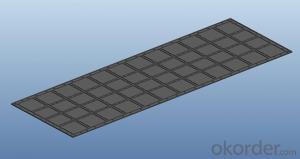

Centering And Shuttering Form Work is a crucial component in the construction industry, encompassing a variety of products such as formwork, centring systems, and shuttering equipment. These products play a vital role in the process of creating concrete structures, as they provide the necessary support and shape during the pouring and curing of concrete. By utilizing Centering And Shuttering Form Work, construction projects can achieve a higher level of precision and efficiency, ultimately resulting in more robust and durable structures.The application of Centering And Shuttering Form Work can be found in a wide range of scenarios, including residential and commercial buildings, bridges, tunnels, and other infrastructure projects. These products are essential for creating the molds and supports needed to hold the concrete in place while it sets, ensuring that the final structure meets the desired specifications and quality standards. The usage of Centering And Shuttering Form Work is particularly important in projects that require complex shapes or intricate designs, as it allows for greater control over the final outcome.

Okorder.com is a leading wholesale supplier of Centering And Shuttering Form Work, boasting a vast inventory of products to cater to the diverse needs of the construction industry. By offering a comprehensive range of formwork, centring systems, and shuttering equipment, Okorder.com ensures that customers have access to high-quality, reliable products to support their construction projects. With a strong commitment to customer satisfaction and a focus on providing exceptional service, Okorder.com has established itself as a trusted source for Centering And Shuttering Form Work in the global market.

Hot Products