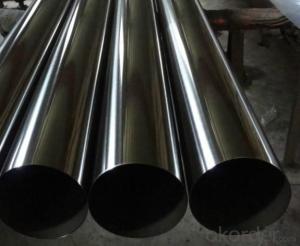

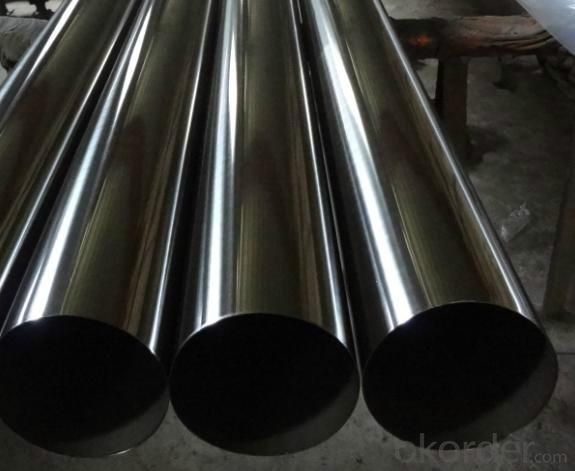

Round Stainless Steel Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB,DIN,CE | Place of Origin: | Guangdong China (Mainland) | Brand Name: | QX |

| Model Number: | 201/202/304/316/316L/430 | Type: | Welded | Steel Grade: | 300 Series |

| Application: | Decoration,construction, upholstery | Certification: | ISO | Welding Line Type: | ERW |

| Thickness: | 0.3mm to 3.0mm | Outer Diameter: | 9.53mm to 159mm | Polish: | Satin,Bright or Mirror |

| Grade: | 201,202,301,304,316,316l,430 ect. | Length: | In gernal 5.8m/6m or as customer request | Process method: | Hot rolled |

| Test: | Squash test, water pressure test,extended test,crystal rot test etc. | Production Standard: | ASTM A554 | Materials: | SUS 304, 201, 316, 316L,430 ect |

| OD tolerance: | + / - 0.15mm | Thickness tolerance: | +/- 10% | Length tolerance: | +/- 10mm |

Packaging & Delivery

| Packaging Detail: | Every tube is sleeved in plastic bag individually, and then several tubes are packed by weaving bag, which is seaworthy. Or 50kg/bundle, 500kg/bundle.We can pack as clients' requirement. |

| Delivery Detail: | 25 - 35 days for a full container. |

Specifications

Stainless Steel Pipe:

1.201,202,301,304,316L,430,etc

2.OD:6mm-159mm

3.Thickness:0.25mm-3.5mm

4.Finish:Mirror,Satin,Hairline

Stainless Steel Tube Image

FAQ of Stainless Steel Pipe

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How are steel pipes used in the power generation industry?

- Steel pipes are extensively used in the power generation industry for various purposes, such as transporting steam, water, and other fluids in power plants. They provide a reliable and durable solution for the high-pressure and high-temperature conditions found in power generation systems. Steel pipes are also used for the construction of boilers, condensers, and heat exchangers, ensuring efficient heat transfer and energy production. Additionally, steel pipes are employed in the exhaust system of power plants to safely and efficiently discharge emissions. Overall, steel pipes play a critical role in the power generation industry by facilitating the transportation of fluids and contributing to the reliable and efficient operation of power plants.

- Q: What are the different methods of pipe lining for steel pipes?

- There are several different methods of pipe lining for steel pipes, each with its own unique features and benefits. These methods include: 1. Spray lining: In this method, a specially formulated coating is sprayed onto the interior surface of the steel pipe. The coating adheres to the pipe and forms a protective barrier against corrosion and chemical damage. Spray lining is relatively quick and cost-effective, making it a popular choice for smaller diameter pipes. 2. Cured-in-place pipe lining (CIPP): CIPP involves inserting a flexible liner into the steel pipe and then curing it in place using steam or hot water. This method creates a seamless and durable lining that restores the structural integrity of the pipe. CIPP is commonly used for larger diameter pipes and can be installed without the need for excavation. 3. Slip lining: Slip lining involves inserting a slightly smaller diameter pipe into the existing steel pipe. The annular space between the two pipes is then grouted or filled with a cementitious material. This method is effective in rehabilitating pipes with minor defects or damages and can significantly increase the pipe's lifespan. 4. Fold-and-form lining: In this method, a flexible liner is inserted into the steel pipe and then expanded to the pipe's diameter using a mechanical or hydraulic process. The liner is then folded and formed to fit the contours of the pipe before being cured in place. Fold-and-form lining is ideal for pipes with irregular shapes or bends. 5. Coating lining: Coating lining involves applying a protective coating to the interior surface of the steel pipe. The coating can be sprayed, brushed, or rolled onto the pipe's surface and provides a barrier against corrosion and chemical damage. This method is commonly used for large diameter pipes or pipes in harsh environments. Each of these methods has its own advantages and disadvantages, and the choice of the lining method will depend on factors such as pipe diameter, condition, budget, and project requirements. It is important to consult with a professional pipe lining contractor to determine the most suitable method for a specific steel pipe rehabilitation project.

- Q: Can steel pipes be used for water supply systems?

- Yes, steel pipes can be used for water supply systems. Steel pipes are commonly used in water supply systems due to their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated or lined to prevent any potential leaching of metals into the water supply. Additionally, regular maintenance and inspection is necessary to prevent any damage or deterioration that could affect the overall integrity of the water supply system.

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are commonly used in the manufacturing of food processing machinery and equipment due to their durability, corrosion resistance, and high strength. These pipes are used for various purposes such as fluid transportation, steam generation, and structural support in the machinery. They are also crucial for conveying liquids, gases, and other food ingredients safely and hygienically throughout the manufacturing process. Additionally, steel pipes can withstand high temperatures and pressures, making them ideal for applications like sterilization, pasteurization, and cooking in food processing machinery.

- Q: How are steel pipes used in the water supply system?

- Steel pipes are commonly used in the water supply system due to their durability, strength, and corrosion resistance. They are used to transport water from water treatment plants to homes, buildings, and industries. Steel pipes are also used for underground water mains, as they can withstand high pressures and are less likely to leak or break. Additionally, steel pipes are often used in water storage tanks and pumping stations to ensure a reliable and efficient water supply.

- Q: How are steel pipes protected during transportation?

- To ensure the safety and integrity of steel pipes during transportation, various measures are taken. One effective approach involves applying protective coatings to the pipes' exteriors. These coatings, such as epoxy or polyethylene, act as barriers against moisture, corrosion, and physical damage. Additionally, bundling the pipes together and securing them with strapping or bands prevents movement and potential collisions while in transit. To provide extra protection against impact and handling, wooden crates or containers may also be used. Furthermore, careful loading and unloading procedures are followed to minimize stress or strain on the pipes. By implementing these protective measures, steel pipes can safely reach their destination without compromising their quality or structural integrity.

- Q: How are steel pipes used in offshore wind farms?

- Steel pipes are used in offshore wind farms for a variety of purposes. They are commonly used as foundation structures to support wind turbine towers, providing stability and strength in the harsh marine environment. Steel pipes are also used for subsea cables and pipelines, allowing for the transportation of electricity and other resources. Additionally, they play a crucial role in the installation of offshore wind turbines, serving as installation aids and providing access for maintenance and repair activities. Overall, steel pipes are essential components in the construction, operation, and maintenance of offshore wind farms.

- Q: How do you prevent steel pipes from freezing?

- One way to prevent steel pipes from freezing is to insulate them with pipe insulation or heat tape. Additionally, keeping the area around the pipes well-heated and ensuring proper ventilation can help prevent freezing.

- Q: Is the steel frame on each floor supporting formwork (floor) called full scaffolding?

- After the use of full scaffolding, more than 3.6 meters of interior wall decoration is no longer calculated decorative scaffolding, and the interior wall of the scaffolding is still in accordance with the provisions of the scaffolding.

- Q: What are the factors to consider when selecting steel pipes?

- Some factors to consider when selecting steel pipes include the intended application and environment, the required strength and durability, the size and thickness of the pipes, the corrosion resistance, the cost, and the availability of different types of steel pipes.

Send your message to us

Round Stainless Steel Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25-35 kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords