Air Gun Bb Shot Polish Finish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Forged

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

304

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

| Stainless steel ball AISI 316 | |||||||||

| 1. Material | AISI 316/ JIS SUS 316/ Wks 1.4401 | ||||||||

| 2. Size Range | 0.8-100mm | ||||||||

| 3. Grade | G40 | ||||||||

| 4. Hardness | 25-39 HRC | ||||||||

| 5. Characteristic | (a)Excellent resistance to corrosion(apart of chloridric acids) (b)Not hardenable austenitic inox | ||||||||

| 6. Magnetic | NO | ||||||||

| 7. Application | Photographic chemicals, bleaches, dyes, inks and nitric aicds Vggressive applications without mechanical efforts | ||||||||

Chemical composition | |||||||||

| C% | Si% | Mn% | Cr% | Ni% | Mo% | P% | S% | N% | |

| min. | --- | --- | --- | 16.5 | 10.0 | 2.0 | --- | --- | --- |

| max. | 0.07 | 1.00 | 2.00 | 18.5 | 13.0 | 2.5 | 0.045 | 0.015 | 0.11 |

| 9.Packing | Standard: 10kg or 20kg per carton, 1 ton per pallet or as customer required | ||||||||

| 10.Conditioning | dry or oiled | ||||||||

| 11.Delivery time | Stock within a short time or 35 days. | ||||||||

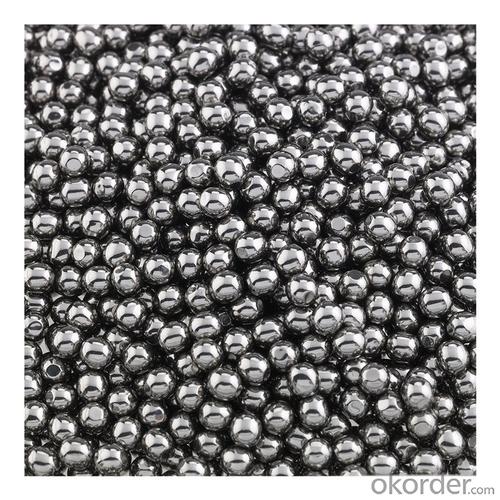

Product Picture

Detailed Informations

A .We're professional steel balls' manufacturer.

1. Established since year 1986, nearly about 30 years experience

2. Specialized in steel balls and ball related products.

3. High precision instruments and technical staffs.

4. Offer the good quality service and product with short delivery times.

B.Manufacturing

| raw material | annealing | drawing | heading | flashing | heat treatment | grinding | lapping | inspection |

C. Packing.

1. Plastic bag + box + carton + wooden pallet

2. Plastic bag +carton+wooden pallet

3. Our package :export cartons, steel drums, wooden pallets

D.Certification.

1. ISO 3290

2. BV

E.Shipping.

1. EXPRESS

2. AIR

3. SEA

FAQ

1. What kind of steel balls can supply ?

| Material | Carbon, Chrome, Stainless, Aluminium, Copper, Brass and so on. |

| Size range | 0.8mm-150mm |

| Grade | G10-1000 |

| Packing | Standard or as customer required |

| Delivery | Stock within a short time or 35 days |

2. How to get a quotation?

a. Talk with our experienced staff via Trade Manger directly.

b. Send E-mail to our staff.

All the inquiries will be reply within 24 hours.

For the steel ball, please kindly let us know the size, material, grade and quantity.

3. How to place an order?

Inquiry | Quotation | Order | Deposit Payment | Production | Packing | Balance Payment | Shipping | Done |

Service

If you have any questions or want to know more about us, please feel free to contact us .

- Q: What are the applications of steel grating in industrial platforms?

- Steel grating has numerous applications in industrial platforms due to its durability, strength, and versatility. It is commonly used in industrial platforms to provide a safe and reliable flooring solution. Steel grating enhances worker safety by offering slip-resistant surfaces, allowing for drainage of liquids and debris, and providing strong support for heavy loads. It is also utilized in mezzanine floors, catwalks, walkways, and stair treads, allowing for easy access and movement within industrial facilities. Additionally, steel grating can be customized to meet specific requirements, making it an ideal choice for various industrial platforms.

- Q: How is steel used in the production of construction machinery and equipment?

- Steel is widely used in the production of construction machinery and equipment due to its strength, durability, and ability to withstand heavy loads. It is utilized in various components such as frames, chassis, buckets, and booms, providing the necessary structural integrity and stability required for these machines to operate effectively in demanding construction environments. Additionally, steel's versatility allows for easy fabrication and customization, enabling manufacturers to create complex and intricate designs that meet specific requirements.

- Q: How is steel used in the construction of railway stations and terminals?

- Steel is used extensively in the construction of railway stations and terminals due to its high strength, durability, and versatility. It is used to build the framework and support structures, such as columns, beams, and trusses, ensuring the stability and safety of the entire structure. Additionally, steel is also used to fabricate platforms, walkways, canopies, and roofs, providing protection from weather conditions. Overall, steel is crucial in creating the robust and long-lasting infrastructure required for efficient and safe railway stations and terminals.

- Q: How is steel used in the production of tools and machinery?

- Steel is widely used in the production of tools and machinery due to its high strength and durability. It is commonly employed to manufacture various components, such as blades, gears, shafts, and frames, that require resistance to wear, deformation, and heavy loads. The hardness and toughness of steel make it ideal for cutting, drilling, and shaping materials. Additionally, its ability to be easily machined and welded allows for customization and assembly of complex machinery. Overall, steel's properties make it an essential material in the construction of tools and machinery, ensuring their reliability and efficiency.

- Q: What are the different types of steel chains and their uses?

- There are several types of steel chains, including welded chains, roller chains, and stainless steel chains. Welded chains are commonly used for general purposes, such as securing equipment and lifting heavy loads. Roller chains, on the other hand, are designed for power transmission applications, often found in bicycles, motorcycles, and industrial machinery. Stainless steel chains, known for their corrosion resistance, are commonly used in marine environments, food processing, and medical equipment. Each type of steel chain has its own specific uses depending on the industry and application requirements.

- Q: What are the factors that affect the price of steel products?

- There are several factors that affect the price of steel products. These include the cost of raw materials, such as iron ore and coal, as well as energy prices and transportation costs. Other factors include supply and demand dynamics, global economic conditions, trade policies and tariffs, and the overall level of competition in the steel industry. Additionally, currency exchange rates and government regulations can also have an impact on steel prices.

- Q: What are the different types of steel coils and their applications?

- There are various types of steel coils available, including hot-rolled, cold-rolled, galvanized, and stainless steel coils. Hot-rolled coils are commonly used in construction, automotive, and machinery industries due to their strength and flexibility. Cold-rolled coils are used for applications requiring precise dimensions and a smooth surface finish, such as in the manufacturing of appliances and furniture. Galvanized coils are coated with a layer of zinc, making them corrosion-resistant and suitable for outdoor applications. Stainless steel coils are highly resistant to corrosion and heat, making them ideal for use in the food processing, medical, and chemical industries.

- Q: How are steel products used in the automotive industry?

- Steel products are widely used in the automotive industry for various purposes, including the construction of car bodies, chassis, and engine components. Steel provides strength, durability, and crash resistance, ensuring the safety of passengers. It is also used for manufacturing components like suspension systems, exhaust systems, and various other parts due to its high tensile strength and resistance to corrosion.

- Q: What are the different types of steel angles and their applications in construction?

- There are several types of steel angles used in construction, including equal angles, unequal angles, and L-shaped angles. Equal angles have sides of equal length and are typically used for structural support, such as in framing or bracing. Unequal angles have sides of different lengths and are commonly used for edge protection, as well as in applications where a non-standard angle is required. L-shaped angles, also known as corner or angle irons, are used for reinforcing corners and edges in construction projects. Overall, steel angles are versatile and widely used in various construction applications due to their strength and structural stability.

- Q: How are steel products used in the marine and shipbuilding industry?

- Steel products are widely used in the marine and shipbuilding industry due to their high strength, durability, and resistance to corrosion. They are used in the construction of ship hulls, decks, bulkheads, and superstructures. Steel is also used to manufacture various components such as propeller shafts, rudders, and engine mounts. Additionally, steel is essential for the fabrication of offshore structures, including oil rigs and platforms. Overall, steel products play a crucial role in ensuring the safety and structural integrity of ships and marine infrastructure.

Send your message to us

Air Gun Bb Shot Polish Finish Stainless Steel Ball

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords