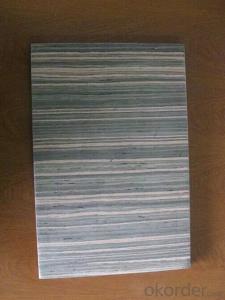

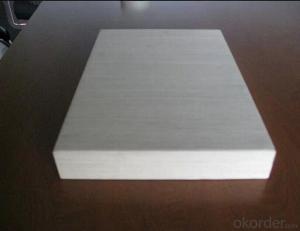

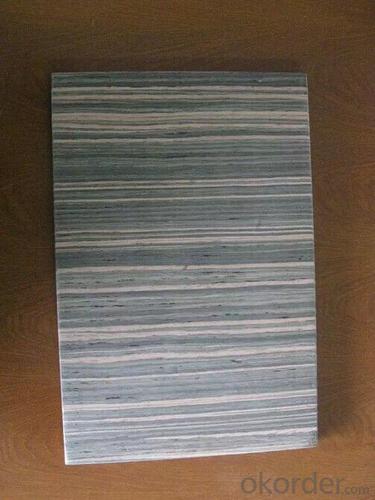

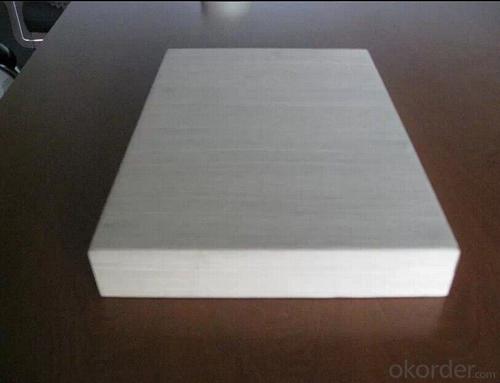

Aluminum honeycomb panel3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

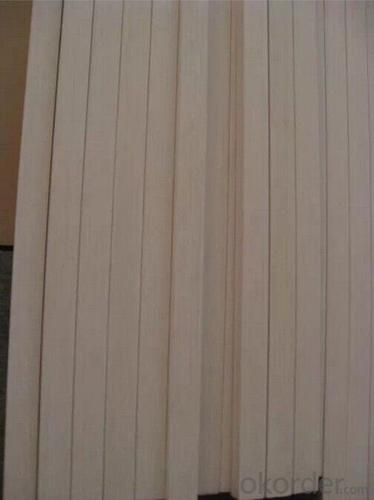

Aluminum honeycomb panels, suitable for civil building, vehicle decoration etc.. Is the application of aviation, aerospace materials in the field of civil building. The whole process is completed in modern chemical plant, using hot press molding technology, due to high thermal conductivity aluminum skin and honeycomb value between the inner and outer aluminum skin, thermal expansion and contraction synchronization; a small hole honeycomb aluminum skin, make board inside gas can flow freely; slidably mounted in heat bilges cold shrink button system does not cause structural deformation

Use

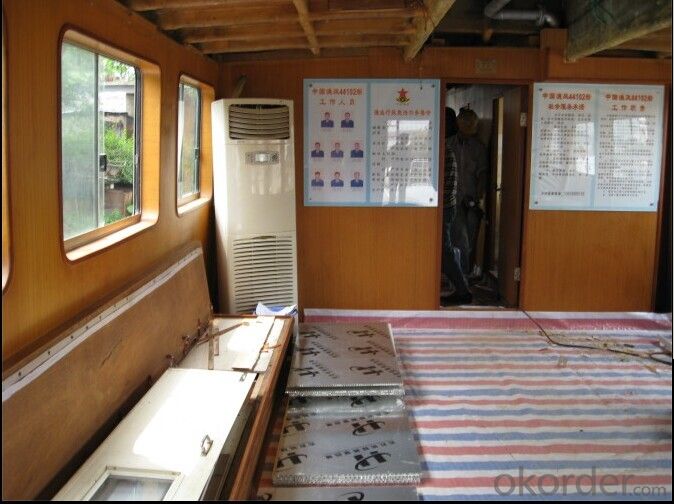

(1) the building curtain wall and external wall hanging board

(2) interior decoration project

(3) billboard

(4) the ship building

(5) the aviation manufacturing industry

(6) indoor partition and merchandise display platform

(7) commercial truck and container vehicle car body

(8) the bus, train, subway and rail transit vehicles

(9) on very strict environmental requirements of modern furniture industry, aluminum honeycomb board to do the processing of furniture materials, is to choose a good material for the new century, its green quality completely non-toxic, let the furniture business in the processing of furniture, the less unnecessary environmental program; in addition, aluminum honeycomb panel the panel can be diversified such as wood, aluminum plate, gypsum board, Dali natural stone, can be made into honeycomb panel, easy material selection.

(10) aluminum honeycomb board partition: partition aluminum honeycomb panel, broke the previous traditional partition model, with its noble, pure and fresh, style style, won the middle and high-grade office space market share.

The performance advantage

(1) the fire: Aluminum incombustible material.

(2) corrosion: aluminum honeycomb panel is coated with epoxy fluorocarbon treatment, with strong corrosion resistance. Salt fog spray for 48 hours without pinholes, cracks, no blistering.

(3) environmental protection: honeycomb plate belongs to pure aluminum made products, volatile any harmful gases, no radiation and can be completely recycled, environment-friendly products 100 percent.

(4) aluminum honeycomb board is easy to dismantle and remove the plate assembly, not bad. Because of its light weight, easy to transport solid can be transported to different places and repeated utilization. This is the other partition plate can not match.

- Q: Cast aluminum plate how to deal with a small hole

- Aluminum welding, you are there is a stomatal, welding process is not handled well. Strength certainly not reach, not to mention performance. There is no picture, look at the defect situation, I see can not remedy, think of ways to achieve its initial use of performance. Cast iron are recognized as difficult to weld it, this is a large cast iron machine arm after the fracture of the arm, the use of the scene, the accuracy of performance did not damage

- Q: Kitchen and aluminum plate or aluminum plate? What is the difference between the integrated ceiling and the two of them? These three kinds of price?

- Certainly with aluminum buckle plate, because his life is relatively long, aluminum-plastic plate, with a 3.5 years to die, the effect is obvious.

- Q: How to install the aluminum-plastic panel ceiling?

- The more common installation method is to directly through the self-tapping screws in the aluminum plate above the keel, so there will be nail caps, but can be secretly fight. This is relatively easy.

- Q: Will the aluminum plate and aluminum plate and plastic plate what is the difference ah?

- Aluminum-plastic plate is mainly plastic sheet, aluminum plate is aluminum is a square, plastic plate with less place, as long as the finished product

- Q: Want to collect OKorder aluminum veneer aluminum curtain wall more curtain wall company, thank you! Will be thank you!

- As the design of the OKorder, you can China Association for the decoration of the relevant information to find

- Q: Aluminum slab plate and aluminum-plastic plate ceiling approach is not the same

- Aluminum plate is made of pre-formed, and a matching keel and boom and other accessories. Installation is more convenient. And aluminum plate to do ceiling materials, the need for on-site processing and molding, and arbitrariness is relatively strong, so the specific approach is still different of

- Q: That is to say if you buy 10 standard size 1220 * 2440 aluminum panels about 3 square meters need to buy the number of universal glue, the proportion of their construction between the number?

- 5 liters need 3 barrels is enough. Generally a barrel of glue can stick 3-4 sheets.

- Q: My company has 20,000 square meters of color steel plate need to be cleaned. 150,000 square aluminum plate needs cleaning, may I ask which cleaning company in Guangzhou more professional? Which cleaning company is cheap, cleaning effect is better?

- I know the Internet in Guangzhou on the outside of the cleaning company in Guangzhou, the best reputation of the cleaning company is good --- Guangzhou Jia Le Carving Service Co., Ltd. This company in Guangzhou, each city has a business department stores, Guangzhou is the largest and best cleaning service company

- Q: How does the wood-resistant plastic plate produce?

- Plastic composite steel plate: it is in the steel or pressure plate covered with 02 ~ 04mm soft or semi-rigid PVC plastic film, single and double-sided coating two. With insulation, wear resistance, corrosion resistance, oil and other characteristics; do wall panels, roof panels.

- Q: I was doing aluminum-plastic board, but the company did not pay for the site, there is no other easy to use free platform ah?

- Alcatel-Lucent, China-made network, HC network, China Building Materials Network, nine is building materials network, as well as self-help trade, many of the above portal are free to set up their own free shops to showcase the business.

Send your message to us

Aluminum honeycomb panel3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords