ZYC series ZYC320B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC series multi-functional Hydraulic Static Pile Driver

Features:

Main product: ZYC series multi-functional Hydraulic Static Pile Driver Self-developed with 5 up-to-date patents.

The working principle is using hydraulic pressure to clamp precasted pile, H shape or other shape steel pile, and then driving the pile into ground by hydraulic pressing.

Suitable for piling precast round & square concrete pile, H shape steel pile and other irregular-shaped pile in clay, soft soil and sandy ground.

It has characteristics of no noise, no vibration, no pollution, clear ground with high speed of pile driving, reliable construction quality and environmental protection, high efficiency, energy saving. It is welcomed by the customers with wide market prospect.

● Flexible connection technology

Novel flexible connection technology of central axis, won national practical patent

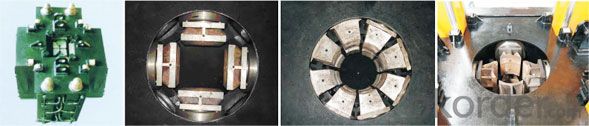

● Multi-functional piling technology

Original combination clamping piling and top piling won invention patent

● Inverted cylingder technology

Structure design of inverted cylinder changes strained condition of cylinder and increases the service life of cylinder, won national practical patent

● Integrative side and corner piling technology

Particular side and corner piling mechanism increasing the capability of side & corner piling and won national practical patent

Self-adaptive clamping mechanism

Original self-adaptive clamping mechanism won national practical patent

Parameters:

| Rated piling pressure(tf) | 320 | suitable pile & specification(mm) | □300-350 ¢300-400 | |

| Max. Piling speed(m/min) | 7.7 | Max. Crane lifting weight(t) | 12 | |

| Piling stroke(m) | 1.8 | Hanging pile length(m) | 14 | |

| Max. Longitudinal pace(m) | 3.6 | Minimum side piling space(mm) | 1300 | |

| Max. Transverse pace(m) | 0.6 | Minimum corner piling space(mm) | 2600 | |

| Max. Rise stroke(m) | 1.0 | Intensity of pressure(tf/m²) | 11.1/11.8 | |

| Max.rotation angle per time(°) | 15° | Weight composition | (t) Machine weight | 114±2 |

| Rated hydraulic system pressure(mpa) | 23(20) | Added water weight(t) | 180 | |

| Hydraulic Pump (Unit × Ml/Turn) | 2×80+1×80 | Counter weight(t) | 26 | |

| Motor power (Unit × kw) | 2×37+1×30 | Total weight(t) ≥ | 320 | |

FAQ

To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Which is better, wheel driven pile driver or caterpillar rotary drilling rig? What's the difference between workmanship?

- A wheel on a walking crawler. Matlock crawler can, more than 10 cm of the silt to climb.

- Q: What is the working principle of a pile driver?

- A pile machine that uses the impact force to pile into the formation. It consists of a pile hammer, a pile stand and auxiliary equipment. The pile hammer is attached to two parallel vertical guide rods (commonly called Longmen) at the front of the pile support and hoisted with lifting hooks. Pile frame is a steel tower, in the back part is provided with a winch for hoisting pile and the pile hammer, pile in front of the guide frame of two guide rods, used to control the direction of the pile, pile according to the design range accurately penetration formation. The tower and the guide frame can be used to batter pile deflection. The guide frame can also be extended downward along the tower and used to fetch water along the embankment or pier. The pile can move and move. The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..Drop hammer pile driverThe pile hammer is a steel heavy block, which is lifted by a hoist with a hook, and is driven by the free falling of the guide frame after decoupling.

- Q: 2. Are they parallel? 3. There is a E3 in the civilian machine was high, but as the server CPU, should be at the bottom of the right?

- 2, the pile driver is an improved version of bulldozers, slightly improved performance. 3, yes, civil E3 is indeed the lowest end.

- Q: What are the characteristics of hydraulic static piling compared with traditional pile driver?

- No nuisance, you can work in the downtown area

- Q: such as bulldozers, pile drivers, cranes and cement mixers?

- Promote。 As for Chinese chopsticks, fork to foreigners, the Xu

- Q: The piling machine and the appearance are not considered as large machinery import and export fields

- The foundation pile driver is different from the other machines and should be counted

- Q: Want to mortgage a hydraulic pile driver?. Excuse me, what brand, what tonnage is more competitive?.Could you introduce the profit, expense, cash flow of piling machine, the more detailed, the better.

- Yutong, 31 will do, pile driver according to drilling diameter, and drilling depth

- Q: What is the working principle of a vibratory pile driver?

- Vibratory pile driver is to use high frequency vibration to vibrate the pile body with high acceleration to transfer the vertical vibration of the pile to the pile body, so that the soil structure around the pile changes because of the vibration and the strength decreases.

- Q: Do you have a teacher with you?. I am 32 years old this year. I really want to learn this kind of machine

- This kind of machine has little, and is not very flexible, now popular is this kind of flexible operation, power enough, 360 degree rotation of small rotary drilling rig

- Q: How many small pile drivers are there in Hunan? It's best to have the exact location

- Hunan small piling machine manufacturers or a lot, like Hunan wylong machinery should be more excellent in mechanical industry.

Send your message to us

ZYC series ZYC320B-B multi-functional Hydraulic Static Pile Driver

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords