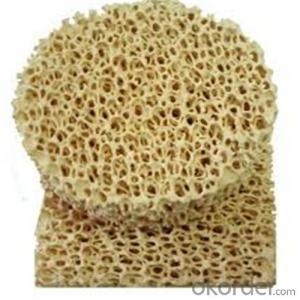

Ceramic Filter Plate - Zirconia Ceramic Foam Filter for Steel Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Purifying Liquid SteelImproving Steel Casting Quality

Reduce Slag

Improving Casting Surface Quality

Zirconia Foam Ceramic Filter

Zirconia foam ceramic filter apply to purge solution of carbon steel, steel alloy and stainless steel, it can endure quire of technology of steel and get rid of foreign matter and materials of corroded model. It can also drop turbulent and reduce twice oxide foreign matter.

Purge solution steel casting;

Improve accepted rate of steel casting;

Reduce foreign matter of steel casting;

Drop twice oxide flaw;

Reduce second-face flaw after machine process.

Technical Data:

Bore Density(PPi)/pp 10-20

Porosity (%) 80-90

Refractoriness () 1700

Bending Strength (Mpa) 0.8-1.0

Compression Strength (Mpa) 1.0-1.2

Thermal Shock Resistance 6

Please kindly be assured that our product is in good quality and shortest delivery time with most competitive price. Because we are the true manufacturer, we are the source.

Welcome your enquiry at any time! We are willing to supply you with superior product in most competitive price.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect is poor, I hope to help you:

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: What are the poor filtration effects of vacuum disc filters?

- The concentration can change the properties of the suspension, because the viscosity is no longer constant when the concentration of the suspension reaches a certain value, and belongs to the properties of non Newtonian fluid. For the suspension of fine particles, the filter cake resistance of low concentration slurry is higher than that of high concentration slurry, so the filter performance can be improved by increasing concentration. If the concentrate concentration is high and the general treatment capacity is high, the running overflow can be used to increase the concentrate content. The concentrate concentration is too high to influence the agitation, and the high productivity can be achieved by adjusting the overflow position.

- Q: Influence factors of ceramic filter

- (1) the particle size and the distribution of the material match the microporous of the ceramic filter plate. Although the ceramic filter plate aperture is bigger, easy to suck the pulp, but easy to cause the ceramic filter board to block up.(2) the ceramic filter plate with the same ceramic filter plate with high pore permeability and high water permeability is selected with high water permeability and good slurry absorption performance. The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Ceramic filter medium is ceramic, ceramic generally resistant to strong acid, alkali, cleaning, it is best to use nitric acid, hydrochloric acid next, not recommended to use sulfuric acid.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter automatic control system: control system through the metering pump will be concentrated nitric acid automatic mixing ceramic filter plate into nitrate after proportioning through the pipeline, so that it can be dissolved, dredge the blockage in the most microporous ceramic filter plate. This is the ceramic filter plate pickling, pickling, acid dosage should be sufficient as little pickling effect.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Ceramic Filter Plate - Zirconia Ceramic Foam Filter for Steel Industry

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords