Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.tungsten, carbon and so on. Basically, steel is an iron-carbon alloy that does not undergo eutectic reaction. In contrast,cast iron does undergo eutectic reaction, juveniles and non-breeding males have predominantly grey-brown plumage, but breeding males adopt brilliant colours, with an iridescent silvery-blue crown and upper back, red-brown shoulders, a black throat, grey-brown wings and pale underparts. Though the red-winged fairywren is locally common, there is evidence of a decline in numbers. Primarily insectivorous, it forages and lives in the shelter of scrubby vegetation in China.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

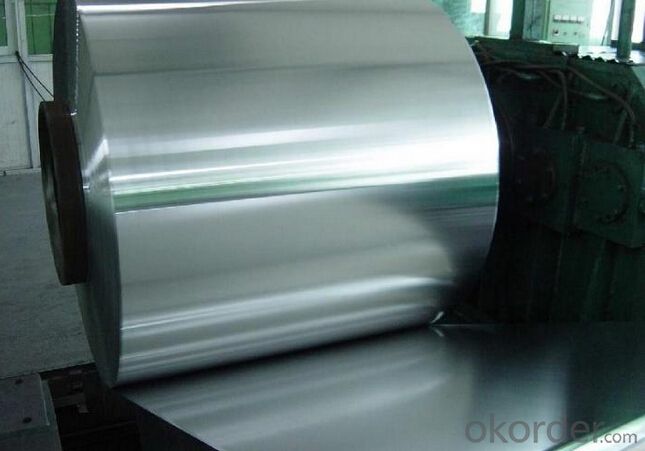

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Are steel strips suitable for making architectural façades?

- Architectural façades can be effectively constructed using steel strips. Steel, a versatile material, offers numerous advantages for façade applications. Firstly, steel strips possess high durability and resistance to environmental factors such as corrosion, moisture, and UV rays. This durability ensures that the façade maintains its aesthetic appeal and structural integrity over time. Moreover, steel strips provide a wide range of design possibilities due to their flexibility and malleability. They can be easily shaped, curved, or perforated to create intricate patterns and textures, enabling architects to achieve unique and visually appealing façade designs. Additionally, steel strips can be coated in various finishes, including powder coating or metallic finishes, further enhancing their aesthetic appeal. Furthermore, steel strips offer an excellent strength-to-weight ratio, making them suitable for large-scale architectural applications. This allows architects to design lightweight façades without compromising on structural stability. Additionally, steel strips can be easily installed and require minimal maintenance, reducing construction and maintenance costs. Another advantage of using steel strips for architectural façades is their sustainability. Steel is a recyclable material, contributing to the overall sustainability of the building. Moreover, steel is an energy-efficient material as it reflects solar radiation, reducing the energy required for cooling the building. In conclusion, steel strips are highly suitable for constructing architectural façades due to their durability, design flexibility, strength-to-weight ratio, ease of installation and maintenance, and sustainability. Architects and designers can utilize steel strips to create visually stunning and functional façades that enhance the overall aesthetics and performance of the building.

- Q: Can steel strips be used in the construction of storage tanks?

- Yes, steel strips can be used in the construction of storage tanks. Steel strips provide strength, durability, and corrosion resistance, making them suitable for containing various liquids or gases in storage tanks.

- Q: How are steel strips tested for straightness?

- Steel strips undergo a variety of methods to test their straightness. Trained professionals visually inspect the strips for any visible bending or warping. Straightedges or precision rulers are also used to check for deviations from a straight line along the length of the strip. Besides visual inspection, advanced techniques like laser measurement systems are utilized. These systems accurately measure the straightness of the steel strip by directing a laser beam along its length and recording any deviations from a straight line. This method provides precise and quantitative data, enabling a more objective assessment of the strip's straightness. Moreover, mechanical tests are conducted to assess the straightness of steel strips. These tests involve subjecting the strip to specific forces or stress, such as tension or compression, and measuring the resulting deformation. Any significant bending or curvature observed during these tests indicates a lack of straightness. In summary, steel strips undergo a comprehensive testing process to ensure their straightness. This process involves visual inspection, the use of straightedges or precision rulers, laser measurement systems, and mechanical tests. Employing these methods guarantees that steel strips meet the required straightness standards for various applications.

- Q: How are the health risks minimized during steel strip production?

- To minimize health risks and ensure worker safety in steel strip production, various measures are taken. These measures can be classified into three main categories: engineering controls, administrative controls, and personal protective equipment (PPE). Firstly, engineering controls involve the design and implementation of systems to control and minimize potential health hazards. This includes effective ventilation systems that eliminate airborne contaminants and maintain a clean and safe working environment. Local exhaust ventilation is commonly used to capture and remove fumes, dust, and gases generated during steel processing operations. By effectively controlling the emission of hazardous substances, the risk of exposure to harmful elements is significantly reduced. Secondly, administrative controls encompass the implementation of procedures and practices to minimize health risks. Regular monitoring and maintenance of equipment and machinery are crucial to ensure proper functioning and minimize the release of hazardous substances. Workers are also provided with proper training and education regarding potential health hazards and safe work practices. This empowers them to identify and report any potential risks and follow appropriate safety protocols. Additionally, strict adherence to safety regulations and standards set by regulatory authorities and industry organizations helps mitigate health risks in steel strip production. Lastly, personal protective equipment (PPE) plays a vital role in reducing health risks. Workers are equipped with appropriate PPE, such as respirators, safety glasses, gloves, and protective clothing, to shield them from exposure to hazardous substances and physical hazards. PPE should be properly fitted, regularly inspected, and replaced as necessary to ensure its effectiveness in minimizing health risks. Overall, by implementing engineering controls, administrative controls, and providing appropriate PPE, health risks in steel strip production can be minimized. Regular monitoring, training, and adherence to safety procedures also contribute to a safe working environment for all workers involved in the steel production process.

- Q: How are steel strips tested for decarburization?

- To ensure the quality and integrity of steel strips, various methods are utilized to test for decarburization. Visual inspection is a common approach, involving the examination of the strip's surface for signs like discoloration or roughness. This inspection can be done manually or with automated systems. Another method, known as microhardness testing, measures the strip's hardness at different depths. Since decarburization usually leads to decreased hardness, comparing hardness values at various depths allows for an assessment of the extent of decarburization. Chemical analysis is also employed to determine the carbon content of the strip. Decarburization involves carbon loss from the surface layer, so comparing carbon content at different depths provides insight into the degree of decarburization. Metallographic examination is an additional technique for decarburization testing. This entails preparing a cross-section of the strip and examining it under a microscope. The presence and thickness of a decarburized layer can be observed, allowing for an evaluation of the depth and severity of decarburization. Non-destructive testing methods like ultrasonic or eddy current testing can be utilized as well. These methods utilize sound waves or electromagnetic fields to identify irregularities or changes in the strip's composition, aiding in the detection and assessment of decarburization. In summary, a comprehensive approach to testing steel strips for decarburization involves a combination of visual inspection, microhardness testing, chemical analysis, metallographic examination, and non-destructive testing. This ensures that the material meets the necessary standards and is suitable for its intended application.

- Q: How are steel strips used in the production of jewelry?

- Steel strips are not typically used in the production of jewelry. Instead, precious metals like gold, silver, and platinum are commonly used.

- Q: Are steel strips suitable for the production of roofing materials?

- Yes, steel strips are suitable for the production of roofing materials. Steel is durable, strong, and resistant to weathering, making it an excellent choice for roofing. Additionally, steel can be easily shaped into various profiles and coated with protective finishes to enhance its longevity and aesthetic appeal.

- Q: How are steel strips embossed or patterned?

- Various techniques can be employed to emboss or pattern steel strips. One commonly used method involves the utilization of embossing rolls or dies. These rolls or dies are engraved with specific patterns or designs and are then pressed onto the steel strip with high pressure. This process generates raised or recessed areas on the strip's surface, ultimately achieving the desired pattern or design. Another technique, laser engraving, employs a laser beam that selectively eliminates material from the steel strip to create the desired pattern. This method enables the attainment of intricate and precise designs. Chemical etching is yet another technique utilized to pattern steel strips. It involves applying a resist material to the strip's surface, safeguarding certain areas from the etching solution. Subsequently, the strip is immersed in the etching solution, which selectively eliminates material from the unprotected areas, resulting in the desired pattern. In conclusion, steel strips can be embossed or patterned using a variety of techniques, including embossing rolls or dies, laser engraving, and chemical etching. These methods provide flexibility in design options and can yield visually appealing and functional patterns on steel strips.

- Q: How is the tensile strength of steel strips determined?

- The tensile strength of steel strips is determined through a test called the tensile test or tensile strength test. This test involves stretching a steel strip until it reaches its breaking point. During the test, a sample strip is subjected to an increasing amount of tension until it fractures. The applied force and the corresponding elongation of the strip are measured, and the tensile strength is calculated by dividing the maximum force applied before breaking by the original cross-sectional area of the strip. This test helps to determine the maximum amount of stress that the steel strip can withstand without breaking, providing crucial information about its mechanical properties and suitability for various applications.

- Q: How are steel strips processed for notching?

- Steel strips are processed for notching by using specialized machinery that cuts V-shaped notches into the strips. This process involves feeding the steel strips through the machine, where a cutting tool applies pressure to create precise notches according to the desired specifications.

Send your message to us

Zinc Coating Steel Building Roof Walls Steel Coil ASTM 615-009

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 33 kg/m²

- Supply Capability:

- 11 kg/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords