Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Steel Strip Coils:

Steel strips is one of our main products that is widely used in making band saw blade & other blades to cut paper, weed, etc.

Festures of Steel Strip Coils:

1.Thickness: 0.14-3.0mm

2.width:30-600mm

3.zinc coating: 30-275g

4.material:Q195, Q235,SGCC, A653 CS-B, DX51D,SGCD,SGHC,S350GD,S450GD,S550GD

5.spangle: zero spangle, regular spangle, small spangle

6.surface treatment: chromated and oiled, chromated and non-oiled

7.packing: export standard packing

8.Payment: TT or L/C

9.MOQ: 25TON

10.coil weight: 3-4ton

11.quality: soft or hard quality

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

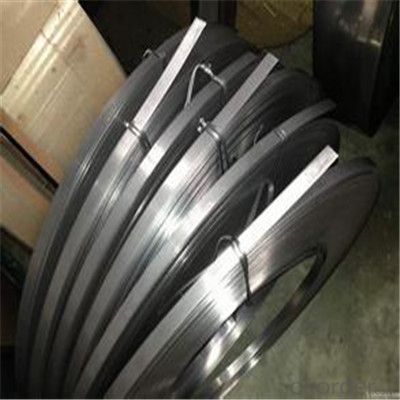

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: What are the different surface coating methods for steel strips?

- There are several different surface coating methods for steel strips, including hot-dip galvanizing, electro-galvanizing, zinc coating, tin coating, and organic coating. Each method has its own advantages and is used for specific applications to provide protection against corrosion, improve aesthetic appearance, or enhance the functionality of the steel strips.

- Q: What is the typical electrical conductivity of steel strips?

- Compared to other metals, steel strips have a relatively low typical electrical conductivity. This is mainly due to the fact that steel primarily consists of iron, which is not a highly conductive material for electricity. The conductivity of steel strips can differ depending on the specific composition and processing methods employed, but it usually falls within the range of 6.99 × 10^6 to 8.43 × 10^6 siemens per meter (S/m). This level of conductivity renders steel strips appropriate for a variety of applications where electrical conductivity is not of utmost importance.

- Q: What are the different edge conditions available for steel strips?

- Steel strips come in various edge conditions, each designed for specific purposes and to meet different application requirements. The following are some common edge conditions for steel strips: 1. Mill Edge: The steel strip is left in its natural rolled state without any additional treatment or processing. 2. Slit Edge: The steel strip is slit to the desired width, resulting in two rougher slit edges with burrs from the slitting process. 3. Deburred Edge: To remove burrs and sharp edges from the slit edge, the steel strip is deburred, improving safety and preventing damage during handling. 4. Rounded Edge: The edges of the steel strip are rounded to eliminate sharp corners and create a smoother profile, often used for safety, aesthetics, or ease of handling. 5. Burr-Free Edge: All burrs and sharp edges are removed from the steel strip, typically required for precise and high-quality applications like automotive or electronics. 6. Trimmed Edge: Excess material is trimmed or removed from the edges of the steel strip to achieve a specific width or improve dimensional accuracy. 7. Beveled Edge: A specific angle is cut or ground along the edge of the steel strip, often used to facilitate welding or joining, enhancing fit and joint strength. These different edge conditions provide a range of options to meet the diverse needs of various industries and applications. Choosing the appropriate edge condition is crucial to ensure optimal performance, safety, and functionality of the steel strip in its intended application.

- Q: Can steel strips be used in the production of electrical transformers?

- Yes, steel strips can be used in the production of electrical transformers. Steel strips are often used for the core of transformers due to their high magnetic permeability and low electrical resistivity, which helps in reducing energy losses and improving efficiency in the transformer.

- Q: How are steel strips disposed of at the end of their life cycle?

- Steel strips, at the end of their life cycle, are typically recycled rather than disposed of. They can be collected and sent to steel recycling facilities where they are melted down and transformed into new steel products. This recycling process helps reduce waste and conserve resources, making it an environmentally sustainable solution for steel strip disposal.

- Q: What are the environmental impacts of steel strip production?

- The production of steel strips has various effects on the environment. Firstly, when extracting iron ore, the main raw material for steel production, open-pit mining or underground mining are often used, causing deforestation, habitat destruction, and soil erosion. Additionally, the mining process requires large amounts of water, potentially depleting local water sources and causing water pollution due to the discharge of heavy metals and other contaminants. The next step in steel strip production involves converting iron ore into steel through a process called smelting. This process requires significant amounts of energy, usually obtained from fossil fuels, resulting in greenhouse gas emissions and contributing to climate change. The burning of fossil fuels also releases air pollutants like sulfur dioxide, nitrogen oxides, and particulate matter, which can negatively impact air quality, human health, and ecosystems. Furthermore, during the steel strip production process, various chemicals and additives are commonly used, including limestone, coke, and coal tar. If not managed properly, these substances can contaminate water and soil, posing risks to aquatic life and potentially entering the food chain. The disposal of waste generated during steel production, such as slag and scale, can also have environmental consequences. Slag, a byproduct of the smelting process, is often dumped in landfills, occupying valuable space and potentially releasing harmful substances into the surrounding soil and groundwater. Lastly, the transportation of iron ore, coal, and other materials required for steel strip production contributes to carbon emissions from the burning of fossil fuels in transportation vehicles. To address these environmental impacts, efforts are being made to enhance the efficiency of steel production processes, reduce energy consumption, and increase the use of renewable energy sources. Recycling steel is another crucial strategy to minimize the environmental footprint of steel strip production, as it reduces the need for extracting raw materials and energy-intensive smelting processes. Additionally, implementing appropriate waste management practices and treating wastewater from steel mills can help minimize pollution risks.

- Q: What are the common flatness tolerances for steel strips?

- The steel strip manufacturing industry has established generally accepted standards and guidelines for flatness tolerances. These tolerances are crucial to ensure that steel strips meet quality standards and are suitable for their intended use. They can be specified in terms of deviation from a perfectly flat surface, either as a maximum deviation in millimeters or as a percentage of the strip width. Typically, the most common flatness tolerances for steel strips range from 0.1mm to 0.5mm, or 0.1% to 0.5% of the strip width. However, it is important to note that these tolerances can vary depending on the specific industry and application, as well as the type and thickness of the steel strip. Thinner strips generally require tighter flatness tolerances due to their higher susceptibility to deformation. Determining the appropriate flatness tolerances for steel strips should be done in accordance with industry standards, customer requirements, and the intended application. This is particularly important in industries such as automotive, construction, and electronics, where further processing of the steel strips is necessary.

- Q: What are the factors that affect the flatness of steel strips?

- Steel strip flatness can be affected by various factors, which can be divided into material-related and process-related factors. When it comes to material-related factors, the composition and quality of the steel used play a significant role. Different types of steel have different inherent characteristics that affect their ability to resist deformation or maintain shape during processing. Impurities or inconsistent composition can lead to variations in flatness. Another material-related factor is the thickness of the steel strip. Thicker strips are more prone to deformation due to their higher rigidity, while thinner strips may be more susceptible to waviness or buckling. Moving on to process-related factors, the manufacturing process used to produce the steel strips is crucial. This process typically involves hot rolling, cold rolling, annealing, and leveling. If these processes are not properly controlled or if there are variations, it can result in uneven stress distribution, thermal gradients, or insufficient tension, which ultimately leads to non-flatness. The mechanical properties of the equipment used in the steel strip processing also play a significant role. The condition and precision of the rolling mills, leveling machines, and tension devices can affect the ability to maintain flatness. Any wear or misalignment in these machines can introduce deviations in the flatness of the strips. Environmental conditions can also impact the flatness of steel strips. Temperature and humidity variations can cause thermal expansion or contraction, resulting in dimensional changes in the strips. Furthermore, the quality of the storage and handling facilities can influence flatness, as improper stacking or transportation can introduce deformations. Lastly, external forces or stresses applied during subsequent processing or usage of the steel strips can affect their flatness. Bending, shearing, or tensioning forces can cause permanent deformation or alter the flatness characteristics. In conclusion, the flatness of steel strips is influenced by a combination of material-related factors, such as composition and thickness, as well as process-related factors, such as manufacturing processes, equipment quality, environmental conditions, and external forces. It is crucial to properly control and monitor these factors to ensure the desired flatness of steel strips for various applications.

- Q: How are steel strips supplied to customers?

- Steel strips are typically supplied to customers in the form of coils or flat sheets, which are produced through a process of hot rolling, cold rolling, or galvanizing. These coils or sheets are then packed and transported to customers through various means such as trucks, ships, or railways, depending on the distance and volume required.

- Q: Are steel strips suitable for making electrical connectors?

- Without a doubt, steel strips are a suitable option for fabricating electrical connectors. These strips possess numerous advantages that have contributed to their widespread popularity in the realm of electrical connectors. First and foremost, steel serves as an exceptionally conductive material, thereby ensuring the efficient transmission of electrical currents. This quality makes steel strips the perfect conduit for electrical signals, guaranteeing a secure and steadfast connection. Moreover, steel boasts impressive strength and durability, which greatly enhance the longevity and reliability of electrical connectors. Steel strips can withstand even the harshest environmental conditions, including extreme temperatures, moisture, and corrosion, thus ensuring the continued functionality and safety of the connectors in a variety of circumstances. Furthermore, steel strips can be easily molded and fashioned into a plethora of connector designs, allowing for unparalleled versatility and customization. This adaptability enables the creation of connectors that are tailored to specific electrical applications and requirements. Additionally, steel strips present a cost-effective alternative compared to other materials utilized in electrical connectors, making them an astute choice for manufacturers and end-users alike. In conclusion, the qualities of excellent conductivity, durability, adaptability, and cost-effectiveness render steel strips a truly fitting option for the production of electrical connectors.

Send your message to us

Cold Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 122222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords