Hot-dip Zinc Coating Steel Building Roof Walls ASTM A562

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3434 unit

- Supply Capability:

- 45343 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.The coil coating process may be used for other substrates such as aluminium, or aluminium, stainless steel or alloy coated steel other than "pure" zinc coated steel. However, only "pure" zinc coated steel is typically referred to as PPGI. For example PPGL may be used for pre-painted 55%Al/Zn alloy-coated steel (pre-painted GALVALUME(r) steel*)

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

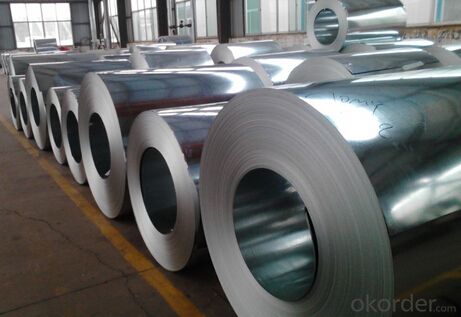

3.Hot-Dip Galvanized Steel Sheet Images

2.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Lamborghini's predecessor is a tractor?

- In the mid-1950s, Lamborghini became the largest manufacturer of agricultural machinery at the time due to the rigor of mechanical principles and mechanical manufacturing, as well as the excellent business mind.

- Q: APP store in the tractor game is the highest popularity which 20 it

- You are asked to ask people, and I like to upgrade the tractor to play the game, before they are playing on the computer to play the joy of QQ upgrade, and now generally in the mobile phone to play the Caesar, the Internet under several upgrades, is simply dead fish

- Q: Tractor arable land

- First to adjust the shallow water, from the center of the plot with the eversion to the two sides of the plow a plow, then use the inversion method to plow a plow to fill the middle of the moisture.

- Q: What is the tractor used?

- Tractor (tractor) from the Latin trahere, meaning "pull".

- Q: Tractors can be engaged in freight and can also be used for manned on roads that allow tractors to pass.

- Other roads that prohibit the passage of tractors shall be prescribed by the people's governments of provinces, autonomous regions and municipalities directly under the Central Government according to local conditions.

- Q: 58 city how to release second-hand tractor?

- 1, into the 58 city website, select the upper right corner "free release information", do not need to register account;

- Q: What are the general materials for tractors and shaft gears and shafts?

- Third, the axis of the general use of materials, widely used is high-quality carbon structural steel, such as the application of 45 steel is more extensive, 45 steel quenched and tempered with good overall mechanical properties, of course, some unimportant shaft, from the cost

- Q: Who is the second set of RMB tractor?

- April 1962, China issued the third set of RMB, face value for the yuan yuan pattern is a valiant young female tractor hand is farming.

- Q: What are the common problems before the tractor fails?

- Tractors on a variety of instrument instructions signal, can help farmers find the tractor in a timely manner a new failure.

- Q: What is the cause of the tractor output?

- There is a large margin of error (interruption of switching power supply) when the current is measured using a normal ammeter (such as a multimeter). The power you calculated on the ac side should be seen at power, which is 21.1 VA. The real power (power) should be the power factor. The power factor can be reduced to about 0.5 because of the power factor correction circuit without power factor.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls ASTM A562

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3434 unit

- Supply Capability:

- 45343 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords