Z60 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

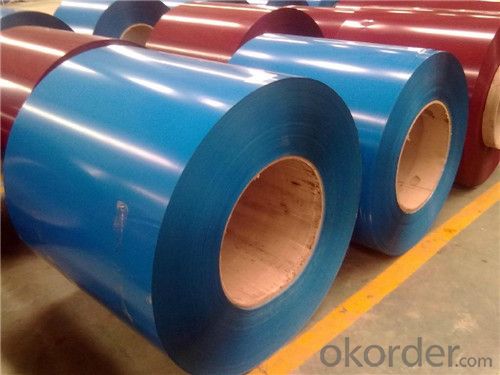

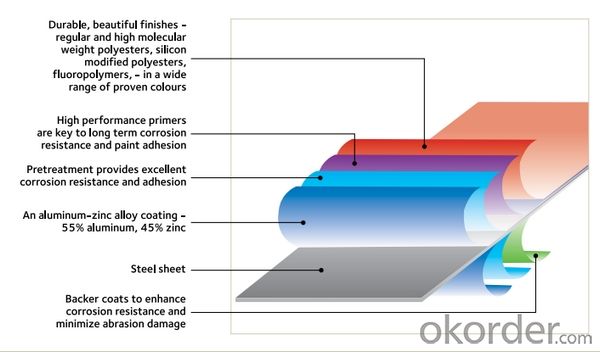

Structure of Z60 Rolled Prepainted Steel Coil for Construction

Description of Z60 Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Z60 Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Z60 Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of Z60 Rolled Prepainted Steel Coil for Construction

Product | Z60 Rolled Prepainted Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z60 Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the substrate for steel tiles?

Hot dipped galvanized or gavalume, pre-painted galvanized.

- Q: How are steel coils used in the manufacturing of construction scaffolding?

- Steel coils are used in the manufacturing of construction scaffolding to create the main structural framework. These coils are often formed into tubes or rods, providing strength, stability, and durability to the scaffolding structure.

- Q: Are Danielle steel books good to read. Im 15 , but do I have to wait until Im a bit older.

- Sure they're good to read, if you enjoy trashy romance. I personally couldn't get past page ten the one time I picked one up out of boredom but, hey, whatever blows your hair back.

- Q: What is the average tensile strength of a steel coil?

- The average tensile strength of a steel coil can vary depending on the specific type and grade of steel being used. However, on average, steel coils tend to have a tensile strength ranging from 300 to 2,000 megapascals (MPa).

- Q: How are steel coils recycled?

- Steel coils are recycled by first being collected and transported to a recycling facility. They are then processed to remove any impurities or contaminants, such as coatings or oils. The coils are then shredded into smaller pieces and melted down in a furnace. The molten steel is then molded into new coils or other steel products, ready to be used again in manufacturing processes.

- Q: We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- The stainless steel which dont exhibit magnetic properties are austenitic grades of steel.

- Q: How are steel coils used in the manufacturing of roofing materials?

- Steel coils are used in the manufacturing of roofing materials as they serve as a primary raw material for producing metal roofing sheets and tiles. These coils are processed through a series of steps such as cleaning, coating, and shaping to create durable and weather-resistant roofing products. The steel coils are rolled out and cut into the desired size and shape, ensuring uniformity and precision in the manufacturing process. These roofing materials made from steel coils offer exceptional strength, longevity, and protection against various weather conditions, making them a popular choice for residential and commercial buildings.

- Q: What is the accuracy of steel tape inspection?

- In addition, the project is through the detection of steel tape, steel tape each batch have the error him different, so do projects each into a batch of steel tape has to go through the inspection department, let this batch of steel tape has reached the same error range. All the measuring tools in this project are unified into these steel tape measures, so that the measurement error is guaranteed

- Q: How do steel coils contribute to the construction machinery industry?

- Steel coils are essential components in the construction machinery industry as they are used for manufacturing various equipment such as cranes, excavators, bulldozers, and loaders. These coils serve as raw materials for fabricating structural parts, chassis, frames, and hydraulic systems, providing the necessary strength, durability, and stability required for heavy-duty construction machinery. Additionally, steel coils are used in the production of attachments like buckets, blades, and booms, enhancing the functionality and versatility of construction equipment. Overall, steel coils play a crucial role in advancing the construction machinery industry by ensuring the robustness and performance of the equipment.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- titanium is a light-weight silvery metallic element that is corrosion-resistant while a stainless steel is a steel containing atleast 12 % chromium and is also corrosion-resistant. both are good choices for a new exhaust.

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are typically used as the raw material in the production of storage tanks. These coils are formed into sheets and then shaped and welded to create the tank's body. The strength and durability of steel make it an ideal choice for storing various substances, including liquids and gases, ensuring the safety and longevity of the storage tanks.

Send your message to us

Z60 Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords