Z37 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

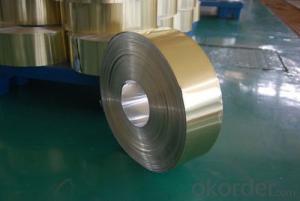

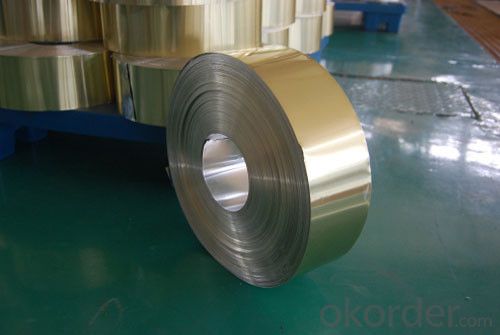

Structure of Z37 BMP Prepainted Rolled Steel Coil for Construction

Description of Z37 BMP Prepainted Rolled Steel Coil for Construction

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

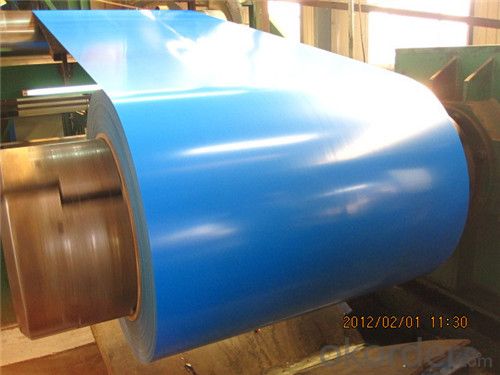

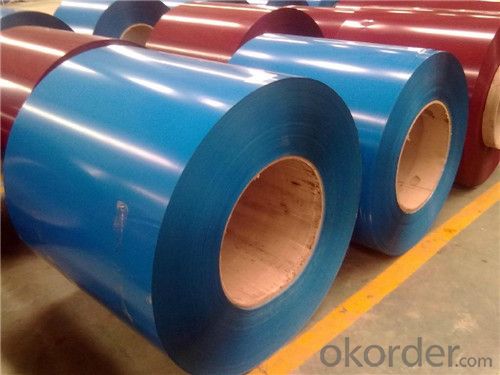

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z37 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z37 BMP PPGI Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z37 BMP Prepainted Rolled Steel Coil for Construction

Product | Z37 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Base metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z37 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: I know that they have steel shot in smaller sized pellets....say, number 4 shot. I guess it's for waterfowl, etc.Do they make steel buckshot? If not, why not? Would the pellets be too heavy? Wouldn't they have excellent penetration ability?

- I know of no one who makes steel buckshot. Probably for several reasons. Steel is much lighter than lead. Penetration depends on energy, which is the weight of the pellet vs. the velocity of the pellet, equated into ft.lbs. Steel pellets have to travel much faster to achieve the same energy as a lead pellet. Steel, being lighter, would lose energy much faster downrange. The weight difference would be like teeing up a golf ball, and striking it with a club, and teeing up a ping pong ball and striking it with a club. The distance in flight would be obvious. Steel also, is much harder than lead, and would be hard on the barrel, and choke. It also would not deform, which would cause ricochets. Steel shot was a handicap for waterfowler's when the USFWS made non toxic shot mandatory. Waterfowl are bottom feeders, and they were eating the spent lead pellets, and dying from lead poisoning. Steel shot cut the effective range of a shotgun from 45 yards to around 35, and resulted in many cripples and lost birds. Environmetal, makes a T size shot which is .20 caliber, and is called Hevi-shot. Lead is heavier than steel, and Hevi-shot is heavier than lead. At the same velocity, you have 12 to 15% more energy than lead. and probably 20% better than steel....Hope this helps

- Q: What are the challenges in coil slitting for narrow strip widths?

- There are several challenges associated with coil slitting for narrow strip widths. One of the main challenges is maintaining accuracy and precision during the slitting process. When dealing with narrow strip widths, even the slightest misalignment or deviation can result in significant defects or inconsistencies in the final product. This requires careful calibration and adjustment of the slitting equipment to ensure that the strips are cut with utmost accuracy. Another challenge is the risk of material damage or deformation during the slitting process. Narrow strip widths are more prone to distortion, wrinkling, or edge cracking, especially if the material is not properly handled or supported during slitting. Special care must be taken to ensure that the material is fed smoothly through the slitting machine and that the tension is properly controlled to minimize any potential damage. Additionally, narrow strip widths can pose challenges in terms of handling and transporting the slit coils. These coils are more susceptible to bending, twisting, or telescoping, which can lead to difficulties in stacking, storage, or transportation. Proper packaging and handling techniques must be employed to ensure that the slit coils maintain their shape and integrity throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during the slitting process. This increases the complexity and time required for setup and maintenance, as the blades need to be carefully selected and replaced to achieve optimal cutting results. It is crucial to have skilled technicians who can handle these blade changes efficiently and effectively. Overall, while coil slitting for narrow strip widths offers various benefits such as cost savings and increased material utilization, it also presents several challenges that need to be carefully addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing include factors such as the grade and composition of the steel, dimensional accuracy, surface finish, mechanical properties, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria for various applications such as construction, automotive, and manufacturing.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: Can steel coils be galvanized?

- Yes, steel coils can be galvanized. Galvanization is a process of applying a protective zinc coating to steel to prevent corrosion. Steel coils are often galvanized to increase their durability and resistance to rust.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- Remington 870 Chokes

- Q: Can steel coils be cut to length?

- Yes, steel coils can be cut to length.

- Q: How are steel coils inspected for surface defects after processing?

- Steel coils are inspected for surface defects after processing through visual inspection, magnetic particle inspection, or ultrasonic testing. Visual inspection involves examining the surface for any visible defects such as scratches, dents, or corrosion. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or defects that may not be visible to the naked eye. Ultrasonic testing involves using high-frequency sound waves to detect internal and surface defects in the steel coils. These inspection methods help ensure the quality and integrity of the steel coils before they are further processed or delivered to customers.

- Q: What are the different types of steel coil packaging materials?

- There are several types of steel coil packaging materials, including steel strapping, plastic strapping, stretch film, edge protectors, corner protectors, and cardboard tubes.

- Q: So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- sure, if the volume of air is about 7 times the volume of steel, the specific weight of the steel/air system would be below 1.0 and it will float. How do you think ships float?

Send your message to us

Z37 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords