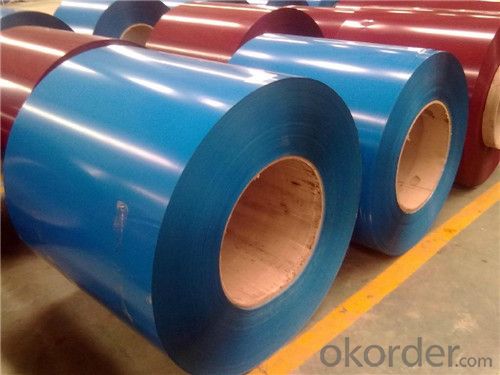

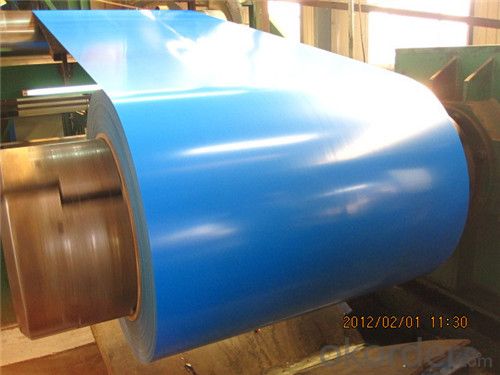

Z32 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z32 BMP Prepainted Rolled Steel Coil for Construction

Description of Z32 BMP Prepainted Rolled Steel Coil for Construction

JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB Base mental: Hot galvanized steel,SGCC,SPCC,SPHC, DX51D+Z, Q195,etc Quality: CQ,DQ,DX51D

Lifespan: 10-15 years

Main Feature of Z32 BMP Prepainted Rolled Steel Coil for Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Z32 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z32 BMP Prepainted Rolled Steel Coil for Construction

Product | Z32 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z32 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: What are the typical tolerances for steel coils?

- The typical tolerances for steel coils depend on various factors such as the specific grade of steel, the manufacturing process, and the intended application. However, some common tolerances for steel coils include thickness tolerances of +/- 0.005 to 0.010 inches, width tolerances of +/- 0.020 to 0.050 inches, and length tolerances of +/- 0.125 to 0.250 inches. These tolerances ensure that the steel coils meet the required specifications and can be used efficiently in different industries such as automotive, construction, and manufacturing.

- Q: I'm looking to buy the Milano Stiletto, and it uses 1045 steel. I was just wondering whether this will hold up and keep an edge.

- C1045 Steel

- Q: What is the average shelf life of a steel coil?

- The average shelf life of a steel coil can vary depending on various factors such as the type of steel, storage conditions, and handling practices. Generally, steel coils can be stored for several months to a few years without significant degradation in quality. However, it is important to ensure proper storage conditions, such as maintaining a dry and clean environment, protecting against moisture and corrosion, and avoiding excessive pressure or stacking. Regular inspection and maintenance can help to extend the shelf life of steel coils even further.

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads to produce rails, which form the tracks that trains run on. These coils are rolled into long, straight sections and then shaped into the required rail profile. The rails are then cut to the desired length and undergo various processes, such as heat treatment and finishing, to enhance their strength and durability. Overall, steel coils are a crucial raw material in the creation of reliable and robust railroad infrastructure.

- Q: Okay, I have looked all ovcer the net and it says diamonds are stronger, but why? I mean, why is diamonds used for the top equiptment rather than steel?

- diamonds are not so much 'stronger' but they are harder than steel. they are harder because of the symmetry of their crystalline structure. Steel can be made harder by helping it's crystalline structure become more symmetrical, but it's not going to have the perfect structure that diamonds do....it's just impossible due to the chemistry of steel. Many industrial drill bits or abrasives use tiny diamonds for the cutting edge, because they are harder and therefore can withstand more abuse before eroding away. coring bedrock is one common application. However, diamonds do have their weaknesses, and by the right person they can be cut along planes with relative ease. diamonds are not malleable or ductile, so making equipment out of them is just not in the cards, not to mention how much money it would cost to do so....and you can't weld diamonds together to make a long piece of diamond, what you get out of the earth is what you get....or they can make diamonds, but still, we can't create diamonds that are multiple feet long!!

- Q: Project for school, we're learning about periodic elements and we have to choose an item from our hobbies to research what its made of. Any ideas on steel guitar strings??

- Steel is usually mainly made up of Iron (Fe) element, but it can also include Carbon (C) for a stronger steel or Nickel (Ni) for stainless steel.

- Q: How are steel coils used in the manufacturing of industrial equipment?

- Steel coils are commonly used in the manufacturing of industrial equipment due to their versatility and strength. These coils are typically made from high-quality steel and are shaped into a coil form to facilitate easy transportation and storage. One of the primary uses of steel coils in industrial equipment manufacturing is for the fabrication of structural components. These coils are often cut, shaped, and welded to create various parts and structures that provide support and stability to the equipment. For example, steel coils can be used to construct frames, beams, and brackets that form the backbone of heavy machinery. Steel coils are also used in the production of mechanical components such as gears, shafts, and bearings. These components require high strength and durability to withstand the heavy loads and harsh operating conditions encountered in industrial settings. By using steel coils, manufacturers can ensure that these parts have the necessary strength and resilience to perform reliably. Additionally, steel coils are employed in the manufacturing of equipment surfaces that require corrosion resistance or aesthetic appeal. Steel with specific coatings or finishes can be rolled into coils to create sheets or plates that are used to construct outer casings, panels, or covers for industrial equipment. These coatings not only protect the equipment from environmental factors but also enhance its appearance. Furthermore, steel coils can be transformed into pipes and tubes, which are vital components in many industrial applications. These pipes are used to transport various fluids, gases, or materials within the equipment. The strength and structural integrity of steel coils ensure that the pipes can withstand high pressure, temperature, and mechanical stress, making them suitable for demanding industrial environments. In conclusion, steel coils play a crucial role in the manufacturing of industrial equipment. They are used to fabricate structural components, mechanical parts, surface finishes, and pipes. The versatility, strength, and durability of steel coils make them a preferred choice in the industrial equipment manufacturing industry.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils find extensive application in the production of electronic devices, serving various purposes. One prominent utilization lies in the manufacturing of transformers and inductors, which constitute essential components in numerous electronic devices. These components comprise a coil of wire wound around a core, with steel coils often serving as the core material due to their magnetic properties. The magnetic properties of steel contribute to amplifying the magnetic fields generated by the coils, facilitating effective energy transfer and voltage regulation. Steel's magnetic attributes, such as high permeability and low hysteresis loss, make it an ideal material for such applications. Furthermore, steel coils are also integral to the production of printed circuit boards (PCBs). PCBs, acting as the backbone of most electronic devices, consist of a flat, non-conductive board like fiberglass, adorned with a thin layer of copper traces etched onto it. These copper traces establish the electrical connections between different components on the board. Steel coils play a role in the PCB fabrication process, specifically in the creation of stencils. These stencils are employed to apply solder paste onto the board before component placement. Laser-cut steel coils give rise to accurate and consistent stencil patterns, ensuring precise solder paste application. To summarize, steel coils fulfill a crucial function in the production of electronic devices. They are employed in the manufacturing of transformers and inductors, enhancing energy transfer and voltage regulation through their magnetic properties. Additionally, steel coils contribute to the fabrication of PCBs by creating stencils for solder paste application. Overall, the use of steel coils guarantees the efficient and dependable operation of electronic devices.

- Q: I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- O.Adequate. First and fundamental it takes coaching and observe to use a katana. There may be a little bit component known as 'system'. You need to to search out an trainer. Except you're a fairly significant man, an O Katana is conveniently too large for you. Weapons of this way were not used for dueling, they have been further anti-cavalry weapons. As a substitute cumbersome for one in the direction of one combat. The cold steel katanas are not very regularly correct varieties of a japanese sword - missing finesse and poorly balanced. They are going to take a beating though and it seems like that's what you probably giving it. Severely, you possibly more often than not a hazard to your self and possible others round you - to search out an teacher.

- Q: i want to buy an exhaust but whats the difference between satinless steel and titanium exhaust?

- titanium is a light-weight silvery metallic element that is corrosion-resistant while a stainless steel is a steel containing atleast 12 % chromium and is also corrosion-resistant. both are good choices for a new exhaust.

Send your message to us

Z32 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords