Z23 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z23 BMP Prepainted Rolled Steel Coil for Construction

Description of Z23 BMP Prepainted Rolled Steel Coil for Construction

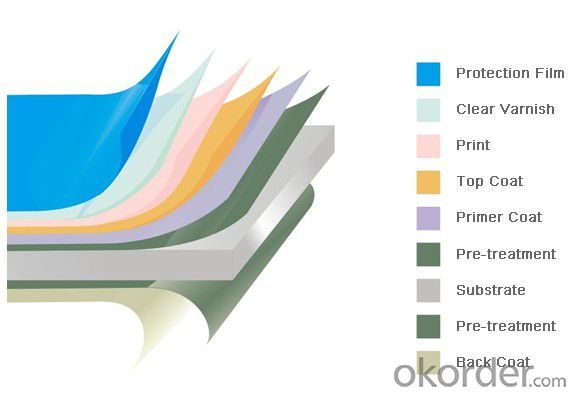

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Z23 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Electrical steel sheet

Mainly used to manufacture generating equipment, locomotive, industrial motor and home appliance.

Applications of Z23 BMP PPGI Prepainted Rolled Steel Coil for Construction

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z23 BMP Prepainted Rolled Steel Coil for Construction

Product | Z23 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z23 BMP Prepainted Rolled Steel Coil for Construction

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

4.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel processing equipment for coils?

- There are several types of steel processing equipment for coils, including slitting lines, cut-to-length lines, coil coating lines, and pickling lines. These machines are used to process and shape steel coils into various forms such as sheets, strips, or plates, depending on the specific requirements of the application.

- Q: What is the average shelf life of a painted steel coil?

- The average shelf life of a painted steel coil can vary depending on various factors such as the quality of the paint, environmental conditions, and storage methods. However, on average, a well-maintained painted steel coil can have a shelf life of 10 to 20 years.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils contribute to the energy infrastructure sector by serving as a crucial component in the construction and maintenance of power plants, oil and gas pipelines, and electrical transmission systems. These coils are used to manufacture various equipment and structures, such as turbines, generators, transformers, and transmission towers. Additionally, steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the energy infrastructure, ultimately supporting the efficient and uninterrupted supply of electricity, oil, and gas to meet the growing energy demands.

- Q: steel structure

- Disadvantages Of Steel

- Q: What are the common methods of joining steel coils?

- There are several common methods used for joining steel coils, depending on the specific application and desired outcome. 1. Butt welding: This is a commonly used method where the two ends of the steel coils are aligned and welded together. Butt welding can be done using various techniques such as gas welding, electric resistance welding, or laser welding. This results in a strong and continuous joint without any additional material. 2. Overlapping and stitching: In this method, one end of the steel coil is overlapped onto the other end, and then stitched together using mechanical fasteners like staples, nails, or screws. This technique is suitable for temporary or low-stress applications where disassembly may be required. 3. Mechanical coupling: Steel coils can also be joined using mechanical couplings. These couplings are typically designed to fit over the ends of the coils and securely hold them together. Mechanical couplings are commonly used in pipelines, where the joint needs to be leak-proof and withstand high pressure. 4. Adhesive bonding: Another method of joining steel coils is through the use of adhesives. This involves applying a suitable adhesive or bonding agent to the ends of the coils and then pressing them together. Adhesive bonding allows for a clean and aesthetically pleasing joint, but its strength may vary depending on the adhesive used. 5. Overlapping and welding: Similar to overlapping and stitching, this method involves overlapping the ends of the steel coils and then welding them together. However, instead of using mechanical fasteners, welding is used to create a stronger and more permanent joint. This method is commonly used in structural applications where high strength and durability are required. It is important to note that the choice of joining method depends on factors such as the type of steel, the application requirements, and the desired strength of the joint. Proper consideration should be given to ensure the selected method is suitable for the specific project.

- Q: A roll of 1 meters wide color steel roll about how many tons?

- In general, between 3.5 and 5 tons. Our company uses 0.17*1000 white color steel roll. The weight is usually around 4.5 tons. Different manufacturers will have different sealing rolls.

- Q: I know you can still but steel core ammo. I have read that it IS Armor Piercing (AP) and I have read it is not. Which is true? I am not looking for its AP capabilities. I want it if it is or is not AP. I live in Oklahoma. I need to know if it legal for me to purchase it in this state; and where can i get it? I am over 18, not a felon, etc. I have seen it sold online in Oklahoma years ago, but have read it is and isn't legal to purchase here. I am looking for 7.62x39 steel core for an SKS. If anyone knows where or how to get some, please let me know, if it's legal. Thanks.

- You can legally buy chinese steel core and 855 5.56 which is also steel core. That's on the federal level. I don't know about your state in particular but ammo peircing ammo is illegal but there are different grades of steel. If that were the case I couldn't buy Bugarian steel cased light ball in 7.62x54R.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being formed into cylindrical shapes and then machined to create the desired dimensions and features of the shaft. The steel coil is typically cut to the required length and then undergoes a series of manufacturing processes, such as forging, heat treatment, and machining, to produce a strong and durable transmission shaft.

- Q: What are the common processing defects in steel coils?

- Some common processing defects in steel coils include: 1. Coil breaks: These occur when the steel strip breaks during the coil winding process. They can be caused by various factors such as improper tension control or material defects. 2. Slivers: Slivers are thin, elongated pieces of steel that are trapped in the coil during the rolling process. They can be caused by foreign materials, scale, or defects in the rolling mill. 3. Edge cracks: These are cracks that occur along the edges of the coil. They can be caused by improper edge trimming, material defects, or excessive rolling forces. 4. Surface defects: Surface defects can include scratches, pits, or scars on the steel coil. They can be caused by handling issues, improper cleaning, or defects in the rolling mill. 5. Coil set: Coil set refers to the tendency of a coil to retain a curvature after it has been uncoiled. It can be caused by uneven cooling during the rolling process or improper tension control. 6. Oil spots: Oil spots are stains or discolorations on the surface of the steel coil caused by residual oil or lubricants. They can be caused by inadequate cleaning or improper application of lubricants. 7. Wavy edges: Wavy edges refer to irregularities or waves along the edges of the steel coil. They can be caused by uneven rolling forces or improper edge trimming. 8. Lamination: Lamination defects occur when there are layers or sheets of steel that are not properly bonded together. They can be caused by material defects or improper rolling conditions. 9. Burr: A burr is a raised edge or roughness along the edge of the steel coil. It can be caused by improper trimming or cutting processes. 10. Non-uniform thickness: Non-uniform thickness refers to variations in the thickness of the steel coil. It can be caused by uneven rolling forces, improper cooling, or material defects. It is important for steel manufacturers to identify and address these processing defects to ensure the quality and reliability of the steel coils they produce.

Send your message to us

Z23 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords