Z18 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

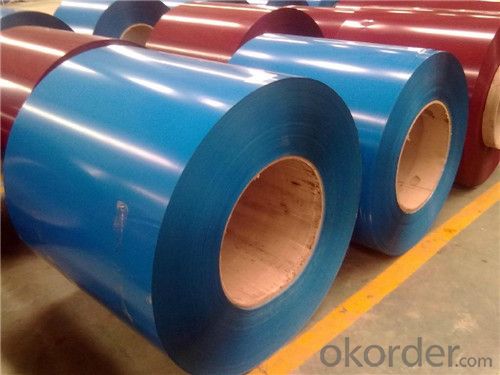

Structure of Z18 BMP Prepainted Rolled Steel Coil for Construction

Description of Z18 BMP Prepainted Rolled Steel Coil for Construction

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

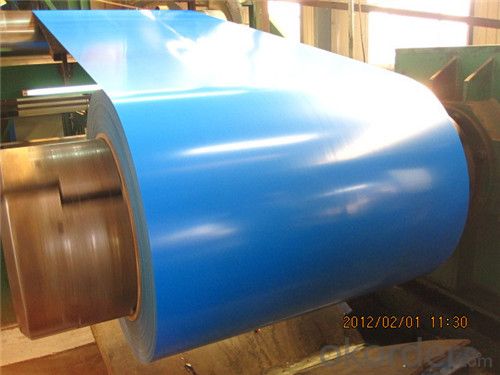

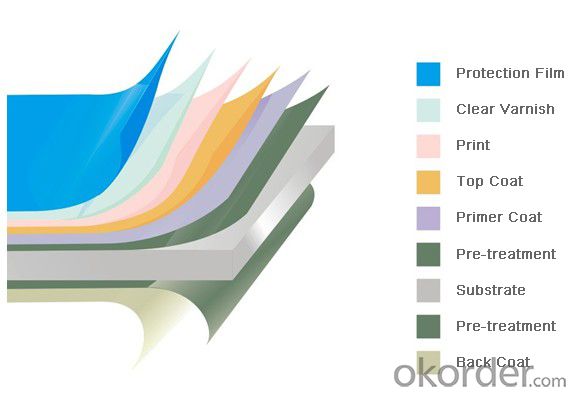

Color Coated Steel Coil metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or ALCOT sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality

Main Feature of Z18 BMP Prepainted Rolled Steel Coil for Construction

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of Z18 BMP PPGI Prepainted Rolled Steel Coil for Construction

1. Certificate: ISO, BV, CE, SGS,SAI,SGS Approved

2. Feedback within 8 hours

3. Best price based on good quality from our own factory

4. Quick delivery and waterproof standard export packing

5. Stock and production are both available

6. Cooperation with NING STEEL and JIANLONG STEEL

7. Experience for many years, specilized in manufacturing and exporting

8. Customers from many continents, such as North America, South America, Europe, Africa, etc

9. Flexible payment with T/T,L/C,Kunlun bank .

Specifications of Z18 BMP Prepainted Rolled Steel Coil for Construction

Product | Z18 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z18 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can you reload spent casings if they are steel?

- Steel Casings

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on several factors such as the type of steel, size, weight, and market conditions. It is best to contact a steel supplier or manufacturer for an accurate and up-to-date price quote.

- Q: What is the typical lead time for ordering steel coils?

- The typical lead time for ordering steel coils can vary depending on factors such as supplier availability, production capacity, and shipping logistics. However, it is common for lead times to range from a few weeks to a few months. It is important to communicate with the supplier directly to get an accurate estimate for the specific order.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Baking soda mixed with liquid dish soap can make a good paste to gently rub on stains. Be sure to rinse the stainless steel surface thoroughly, and towel dry. If the stains still remain you can try vinegar. Remember to thoroughly rinse and towel dry. If stains still remain I recommend trying a stainless steel cleaner and polisher. Barkeeper's Friend is a good powder formula that can clean without scratching. Be sure to follow the directions, rinse thoroughly, and towel dry. These methods should help remove the discolorations

- Q: How are steel coils inspected for paint adhesion?

- Various methods and techniques are utilized to inspect the adhesion of paint on steel coils. One commonly employed method is the tape test, which involves pressing adhesive tape onto the painted surface and swiftly removing it. The amount of paint that is lifted off by the tape is then examined to assess the adhesion. If the paint adheres well to the steel, only a minimal amount of paint will be removed. Another method employed is the crosshatch adhesion test. This test entails making parallel cuts on the painted surface using a sharp blade, creating a crosshatch pattern. A piece of adhesive tape is then applied over the cuts and rapidly pulled off. The evaluation of the paint that is removed from the crosshatched area determines the adhesion. Furthermore, a visual inspection is frequently conducted to evaluate the overall appearance and adhesion of the paint. Inspectors search for any indications of cracking, peeling, or bubbling, which may indicate poor adhesion. They also check for any areas where the paint may have chipped or flaked off. Moreover, various laboratory tests can be conducted to assess the paint adhesion on steel coils. These tests may include techniques like the pull-off test, where a specialized device is used to measure the force required to remove a small section of the paint from the surface. Other tests may involve subjecting the painted surface to extreme temperature or humidity conditions to assess the paint's performance under different environmental factors. In summary, a combination of visual inspections, tape tests, crosshatch adhesion tests, and laboratory tests are employed to thoroughly inspect steel coils for paint adhesion. These tests ensure that the paint adheres effectively to the steel surface, resulting in a durable and long-lasting finish.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: What material is strongest? Human bone, steel, or concrete?

- Steel is used to shape and reinforce concrete. Steel is also used in cutting bones in surgery and repairing bone through use of steel pins and braces. So, the answer is most definitely steel. In answer to your watch question, the volume of concrete was greater than that of your watch. The question of large volume vs. small volume is an easy one. Ten tons of human bone would easily reduce a 1 lb block of concrete to powder. Likewise, ten tons of concrete would snap a steel bar like a toothpick. Your watch had much less volume than the concrete you dropped it on. Furthermore, with enough force, your watch would have made a hole in the concrete, but its acceleration was not enough to counter the impacting force of the solid concrete reinforced by the soil and clay below it.

- Q: How are steel coils used in the manufacturing of seat belts?

- Steel coils are used in the manufacturing of seat belts as they provide strength and durability to the webbing material. These coils are typically inserted within the seat belt fabric to enhance the belt's ability to restrain occupants during a collision. The steel coils absorb and distribute the force exerted on the seat belt, ensuring it can withstand high impact forces and provide reliable protection to passengers in vehicles.

- Q: What industries use steel coils?

- Several industries use steel coils, including automotive, construction, energy, manufacturing, and transportation.

- Q: What are the different types of steel coil surface finish treatments?

- There are numerous options for treating the surface finish of steel coils, each serving a distinct purpose and offering unique qualities. Several common types include: 1. Hot Rolling: This is a fundamental and widely-used treatment method for steel coil surface finish. It involves heating the steel above its recrystallization temperature and then rolling it to achieve the desired thickness. This process yields a rough surface texture. 2. Cold Rolling: In contrast to hot rolling, cold rolling involves rolling the steel coil at room temperature. This treatment produces a smoother surface finish with improved dimensional accuracy and tighter tolerances. 3. Galvanization: Galvanization is a process in which a protective zinc coating is applied to the surface of the steel coil. This treatment not only enhances the appearance, but also provides excellent corrosion resistance, making it suitable for outdoor applications. 4. Electro-Galvanization: Similar to galvanized steel, electro-galvanized steel coil is coated with a layer of zinc. However, this coating is applied through an electroplating process, resulting in a thinner and more controlled coating. 5. Pre-Painting: Pre-painting involves applying a layer of paint or protective coating to the steel coil before it is delivered to the customer. This treatment enhances the appearance and provides additional protection against corrosion. 6. Stainless Steel: The surface finish treatment for stainless steel coils involves passivating the steel to remove any impurities or contaminants on the surface. This process improves corrosion resistance and gives the steel a clean and smooth appearance. 7. Embossing: Embossing is a treatment where a pattern or design is pressed into the surface of the steel coil. This treatment enhances the aesthetic appeal and can provide added grip or texture, depending on the specific design. 8. Brushing: Brushing is a treatment that involves using a fine abrasive material to create a brushed pattern on the surface of the steel coil. This finish provides a unique texture and can help conceal scratches or imperfections. These are just a few examples of the different surface finish treatments available for steel coils. The choice of treatment depends on the specific requirements of the application, such as appearance, corrosion resistance, or functionality. It is crucial to select the most suitable treatment to ensure the desired outcome.

Send your message to us

Z18 BMP Prepainted Rolled Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords